Site sections

Editor's Choice:

- Expansion joints in buildings

- Shaber - what is it and its purpose

- Sharpening wood mills: manual work using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriki in architecture

- Surface scaling - metalwork

- Maximum load on a balcony slab: how much can a balcony withstand in a panel house?

- Projects: legend on drawings for water supply and sewage

- Marking and marking parts How to mark parts with curved contours

- Slotting Tools Slotting Tools

- Mortising tools mortising tools

Advertising

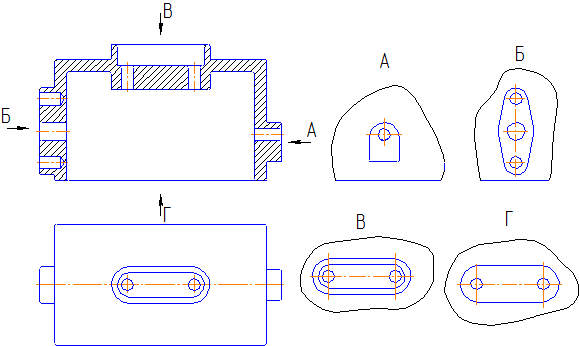

| The number of images in the drawing should be. Select images and lay out a sketch or drawing. What image in the drawing is called the main |

|

All this depends on many factors, but first of all it is determined by the complexity of the geometric shape of the product, its size, as well as the requirements for it. We should strive for a minimal number of images and their simplicity, without prejudice to the ease of reading the drawing - the most important production requirement. So, the geometrical shape of a part limited by surfaces of revolution or the simplest combinations of them can be determined by one image (see Fig. 7.5 and 7.86). The question may arise: what is appropriate to apply - a section, a connection of a part of a view with a part of a corresponding section, a view with drawing lines of an invisible contour?

Practice shows that the most understandable, but also the most time-consuming, is the complete section (Fig. 7.87, a), the less understandable, but also the less time-consuming - to connect part of the species with the corresponding part of the section (Fig. 7.87,6,0), even less clear , but also less time-consuming - a view with invisible contour lines plotted on it (Fig. 7.87, d). The wider use of plotters makes drawing design according to Fig. 7.87, d is acceptable, but it should be used, in particular, in cases where it is possible to avoid the use of lines of the invisible contour for drawing dimensions, signs of roughness, designating bases, etc. (Fig. 7.88).

Perhaps wider should be used local (partial) species (Fig. 7.89), external elements and sections (see Fig. 7.19), cliffs (Fig. 7.90), half of symmetrical images (Fig. 7.91).

However, it is impractical, for example, symmetrical top views in Fig. 2.56 and 7.91 replace them with halves, as this will make it difficult for the designer to understand the drawing.

The rational decision of the drawing largely depends on the correct choice of the main image. But the main image (correctly selected) can be differently oriented on the plane of the drawing. Therefore, when orienting it, you need to think about other necessary images so that, if possible, they do not need to draw lines of an invisible contour (Fig. 7.92, a, b), so that it is convenient to put down the dimensions and put roughness signs.

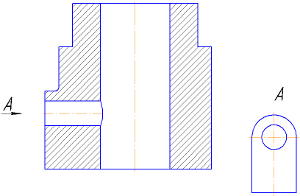

In fig. 7.93, two solutions are given for drawing a roller: on A4 format and A3 format. Both decisions do not contradict clause 1.3 of GOST 2.305-68. Solution "a" may even be preferable to solution "b" if the roller is made on a vertical lathe. The implementation according to the scheme "a" of educational drawings of parts bounded by the surfaces of rotation is quite acceptable if this can significantly reduce the consumption of drawing paper. However, we must remember that long drawings are more convenient to read when the main inscription is located along the larger side of the format.

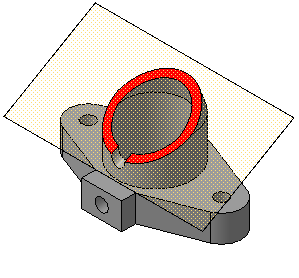

Covers, bearing housings, racks and other similar parts made by casting are usually depicted so that the main machined plane (design base) gets a horizontal position in the drawing. From this base affix dimensions (taking into account auxiliary design bases) to surfaces formed with the removal of a layer of material (machining). The dimensions that determine the casting prior to its processing are affixed from its foundry bases - main and auxiliary.

In fig. 7.91 the main design and foundry bases are conditionally marked with black triangles for clarity. To increase the strength of castings, in order not to increase the wall thickness, stiffeners are used (in Fig. 7.91 there are two of them, right and left, with a thickness of b mm). Technical requirements placed on the drawings parts manufactured by casting (the main part of them for cast iron is shown in Fig. 7.91), in educational drawings, they are usually limited by the requirements of paragraphs 2 and 3. Molding slopes are given to surfaces, if castings do not have structural slopes, weight printing easy model extraction from the mold. Instead of referring to GOST 3212-80 *, they can be set in the drawing in degrees (10 ... 30) depending on the size of the surface height and the casting method. As a rule, only structural slopes are shown in the drawings (as, for example, for a cone 0 34 in Fig. 7.91), noting the requirements for molding slopes in the CT. For molded parts, smooth gradual transitions from one surface to another are also characteristic (Fig. 7.94). The image of the sweeps on the drawings of the parts obtained by the flexible, as well as instructions on the dimensions of the part in expanded form do not give. The development drawing, if necessary, can be produced by a technological document and is not included in the design documentation. However, if the image of the part made by flexible does not give an idea of the shape and size of its individual elements, a full or partial scan is placed on the drawing indicating those dimensions that it is impossible to indicate on the image of the part (Fig. 7.95, a). If all three holes are cut down during stamping, then a full scan is required (Fig. 7.95,6). It is allowed to combine the image of a part of the scan with a view (see Fig. 2.8, a and 7.96). When choosing the scale of images, one should be guided by the convenience of their reading, not to allow thickening of dimension lines, designations of surface roughness and other signs, given that the larger the format of the drawing, the less convenient it is to use. 7.97 is a working drawing. The anchor wheel is depicted in M 20: 1, the teeth in M 200: 1, format A3. The drawing is user friendly. (Record HV 460-510 indicates the required Vickers hardness.) The inscriptions and signs applied to the flat surface of the object, regardless of how they are applied, are depicted in full on the corresponding form (Fig. 7.98). If inscriptions and signs should be applied to a cylindrical or conical surface, then the drawing is placed on the drawing image of the inscription as a scan. Indicate the method of applying inscriptions and signs (engraving, stamping, stamping, etc.), covering the background, inscriptions and signs and other information (Fig. 7.99).

In fig. 7.100 is a drawing of a stamped part having bends, flanges (holes with concave sides) and extrusions (rifts). When making drawings of such details, it is necessary to use GOST 17040-80 *, which contains the dimensional series of these elements (D, R, etc.). So, the question of the number of images, their content, relative position, scale, etc., is decided comprehensively on the basis of from the terms of ease of use of the drawing. \u003e\u003e Drawing: Views. The number of views in the drawings You already know that projection drawing images are called projections. Images used in technical drawings are called views. View- This is an image of the visible part of the surface of the object facing the observer. The standard establishes six main types that are obtained when projecting an object placed inside a cube on all its faces (Fig. 130). Six faces of a hollow cube unfold to align with the frontal plane of projections (Fig. 131). The following species names are established: The names of the species in the drawings do not label. As the main view, the image obtained on the rear face of the cube, which corresponds to the frontal plane of projections, is taken. The subject is located relative to the frontal plane of the projections so that the image on it gives the most complete picture of the shape and size of the subject. The number of views in the drawing should be selected as minimal, but sufficient to understand the shape of the depicted object. In views, it is allowed to show the necessary invisible parts of the surface of the object using dashed lines (Fig. 132).

In the drawing, the distance between the views is chosen arbitrarily, but in such a way that it was possible to apply dimensions. The drawings are not allowed to affix the same size twice, as this clutters the drawing, makes it difficult to read and use in work. Views, as well as projections, are located in projection communication.

If the local view is not located in a projection connection, then in the view it is indicated by an arrow and a letter of the Russian alphabet, and the image of the local view is inscribed with the same letter (Fig. 134).

Local species are allowed to affix dimensions. Questions and Tasks

4. What does the dashed line in the left view mean (Fig. 136)?

N.A. Gordeenko, V.V. Stepakova - Drawing., Grade 9 A correctly executed drawing has clarity and carries a large amount of information that is understandable to a specialist. Therefore, all drawings are carried out in accordance with the established and applicable rules in all areas of activity. They are based on the combined achievements of science, technology and practical experience. The result of this work is standard. In engineering graphics, standards are presented in the form of documents containing a number of requirements and norms established for universal and repeated use. In our country, state standards (GOST) apply, established for all products, as well as for norms, rules, requirements, concepts, designations, etc. To perform this calculation and graphic work, it is necessary, in addition to knowing the standards for the design of drawings, to study and be able to apply standards for the rules for depicting objects and applying dimensions to drawings, the rules for hatching and axonometric projection images. The rules for the depiction of objects in the drawings are established by GOST 2.305-68 "Images - views, sections, sections." Images of objects are performed according to the method of rectangular (orthogonal) projection. In this case, the object is located between the observer and the corresponding projection plane. For the main planes of the projections take six faces of the cube, aligned with the plane in accordance with Figure 6. Figure 6 - Location of the main views in the drawing The number of images should be the smallest, but providing a complete picture of the subject when applying the symbols, signs and inscriptions established in the relevant standards. To reduce the number of images, it is allowed to show the necessary invisible parts of the surface of the object with dashed lines in views in accordance with Figure 7.

Figure 7 - Image of an item indicating invisible parts Kinds View - called the image facing the observer of the visible part of the surface of the object. The following are installed the main views obtained on the main planes of projections: Image on the frontal plane of projections - front view (main view); Image on the horizontal plane of projections - top view; Image on the profile plane of projections - left view; Right view; Bottom view; Back view. The image of an object on the frontal plane of projections is called main view. This image should give the most complete picture of the shape and size of the subject. The names of the species in the drawings do not indicate if they are made in projection communication If the projection connection is broken or the view is not located in the appropriate place, the projection direction should be indicated by the arrow of the corresponding view. Above the resulting image and arrow, the same capital letter of the Russian alphabet should be applied in accordance with Figure 8.

Figure 8– Views and simple sections, and their symbols on the drawing If any part of the subject cannot be shown on the main planes of the projections without distorting the shape, apply additional typesthat get on planes that are not parallel to the main planes of the projections. Additional views are denoted similarly to views on the main projection planes. An additional view located in direct projection connection with the corresponding image is not indicated, and the projection direction is not indicated. It is allowed to rotate the additional view to the position accepted for the subject in the main image. In this case, the type designation should be supplemented by a conventional graphic designation - the “rotated” sign (Fig. 9). If necessary, indicate the value of the angle of rotation.

Figure 9 - Designation of an additional view Local viewcalled the image of a separate, limited surface area of the subject. The local view can be limited by the cliff line or not, if it is necessary to read the shape of the protruding part of the object (Fig. 8). A local view should be indicated on the drawing like an additional view. 28.1. Selection on the drawing of the main image. When constructing drawings, it is important to choose a number of images that allows you to obtain sufficient information about the product. At the same time, one should strive for the smallest number of images giving the necessary characteristics to the depicted object. The number of images in the drawing depends on the complexity of the constructive shape of the object. Often, to provide a complete picture of the shape of a part, a single image is sufficient — a type or section using established signs and inscriptions (for example, signs of diameter, square, indicating the thickness and length of the part, etc.). Examples of such images were given in the manual earlier. To identify the shape of the parts in the drawing is of great importance the correct choice of the main image. Such an image can be a view, a slit or their connection. The main image should give the most complete picture of the shape of the part, the shape of its parts and their sizes, that is, the most complete information. From the correct choice of the main image depends on the number of images in the drawing. For this purpose, the object is tried to be positioned relative to the projection planes so that most of its elements are depicted as visible on the main view. Usually in the drawing, the detail is shown in the position that it occupies during processing. For example, the axis of the parts obtained on the machine turning, in the drawing have horizontally (bushes, shafts and other parts).

28.2. Incomplete images. When making views and cuts in the drawing, it is allowed to use incomplete images. So, if a view or section is a symmetrical figure, then it is allowed to draw half of the part to the centerline (top view in Fig. 173, a) or slightly more than half with drawing a break line (Fig. 173, b). Fig. 173 Instead of the full view, it is allowed to show only the individual elements of the detail in the drawing, if its shape is well read. Figure 174 instead of the top view shows an image of only the keyway.

Fig. 174 If there are symmetrically or evenly spaced elements on the part (for example, holes), then it is allowed to show one or two of them in the drawings, and for the others, only centers should be marked (Fig. 175 and 176). Before the size number indicate their number.

Fig. 175

Fig. 176 Figure 177 shows a drawing in which only a few elements (teeth) of a gear are conventionally shown, and the rest are not shown.

Fig. 177 When depicting an object in one projection, it is allowed to conditionally designate its length. In this case, a Latin lowercase letter l is written in front of the size number (fig. 178).

Fig. 178 Long parts that have a constant (Fig. 179, a) or regularly changing (Fig. 179, b) cross-section can be shown with a gap. The dimension line is not interrupted, the dimension number must correspond to the actual size of the part. It should be borne in mind that partial images with a gap are limited either by a solid wavy line (as in Fig. 179, a and b), or by a solid thin line with a break that extends beyond the contour of the image by a length of 2 ... 4 mm (Fig. 179, c).

Fig. 179

28.3. Additional views. The standard allows to use, besides the main planes of the projections (the faces of the cube) and additional ones, to depict such detail elements that are projected onto the main planes with distortion (Fig. 180, a). An additional plane is placed parallel to the surface of the part element, the image of which must be executed (Fig. 180, b). Then it is combined with the main plane of projections. The image obtained on this plane is called additional view. In Figure 180, to the left of the part in the top view it is conventionally not shown, since when projected on a horizontal plane it is depicted distorted. The additional view gives an undistorted view of the shape and size of this part of the part.

Fig. 180 In the drawing, an additional view is marked with type A inscription, and the direction of the sight is indicated by an arrow with the same letter designation in the drawing. It is allowed to rotate an additional view (Fig. 180, d). In this case, the sign is added to the inscription - "turned", placing it next to the letter. In the case when the additional view is located in the projection connection, as it is done in Figure 180, c, it is not designated and not signed.

28.4. Image smooth transitions. The lines of mutual intersection of the surfaces (Fig. 181, a) on technical drawings are allowed to be shown in a simplified way (unless their exact construction is required). Thus, the line of intersection of two cylinders in the drawing can not be built by points for carrying it along the curve, but can be performed using a compass (fig. 181, b). In this case, the curve curve is replaced by an arc of a circle. In some cases, the curved lines are replaced by straight lines (Fig. 181, c).

Fig. 181 In the drawing, a smooth transition of one surface to another can be represented by a solid thin line, not bringing it up to the contour of the surface (see. Fig. 181, c). A smooth transition can sometimes not be shown at all (Fig. 182).

Fig. 182

28.5. Text and sign information on drawings. The drawing, as established earlier, is a collection of graphic and iconic components that provide complete information about the product. In addition to the image, the dimensions of the part, the names of the material on some drawings put and data on its processing. It is known that in any method of manufacturing parts its surface will not be completely smooth. The combination of all the irregularities that form the surface relief is called roughness. The degree of surface roughness in the drawing is indicated by special signs. Together with the sign indicate the value of the parameter or the numerical value of the roughness (see Fig. 2). On the technical drawings, you can notice the dimensional numbers with additional entries: +0.5; Ø60 ± 0.02, etc. What do they mean? To manufacture a part with absolutely accurate dimensions is almost impossible. As a result, the dimensions will be slightly different than the specified. Therefore, in the drawing, next to the dimension number, indicate the deviation of the size from the given or limiting numbers between which the dimensions may vary. GOST also establishes other signs that give the characteristic details or explaining its geometric shape.

The rules for depicting objects (products, structures and their constituent elements) in the drawings for all industries and construction are established by GOST 2.305 - 2008 * “Images - views, sections, sections”. Images of objects should be performed using the method of rectangular (orthogonal) projection. In this case, the object is placed between the observer and the corresponding projection plane. When constructing images of objects, the standard allows the use of conventions and simplifications, as a result of which the indicated correspondence is violated. Therefore, the figures obtained when projecting an object are called not projections, but images. The faces of the hollow cube are taken as the main projection planes, into which the object is mentally placed and projected onto the inner surfaces of the faces. The faces are aligned with the plane (Figure 2.1). As a result of such projection, the following images are obtained: front view, top view, left view, right view, rear view, bottom view. The image on the frontal plane is taken on the drawing as the main one. The object is positioned relative to the frontal plane of the projections so that the image on it gives the most complete picture of the design features of the object and its functional purpose. Will consider main image selection on the example of such an object as a chair. We depict its projections schematically: We speculate: the functional purpose of the subject - the subject serves to sit on it. In which of the drawings this assignment is most understandable - probably this is Figure 1 or 2, the 3rd is the least informative. The design features of the object - there is a seat, a back, for the convenience of sitting on a chair, located at a certain angle relative to the seat, legs, having the seat at a certain distance from the floor. On which of the figures are these features most clearly presented? Obviously, this is Figure 1. Conclusion - as the main view, we select the projection number 1, as the most informative and most comprehensive information about the functional purpose of the chair and its design features. Similarly, it is necessary to argue when choosing the main image of any object! Images in the drawing, depending on their content are divided into types, sections, sections. View - image of the visible part of the surface of the object facing the observer. Views are divided into basic, local and optional. Main types — images are produced by projecting an object on a projection plane. There are six of them, but most often I use the main three for getting information about the item: horizontal π 1, frontal π 2 and profile π 3 (Figure 2.1). With this projection receive: front view, top view, left view. The names of views on the drawings are not inscribed, if they are located in a projection connection (Figure 2.1). If the top, left and right views are not in projection connection with the main image, then they are marked on the drawing with an “A” type lettering. The direction of sight is indicated by an arrow, indicated by the capital letter of the Russian alphabet. When there is no image on which the gaze can be shown, the name of the species is labeled.

Figure 2.1 Formation of the main species Local view - the image of a separate limited place on the surface of an object on one of the main projection planes. The local view can be placed on any free space of the drawing, marking type “A”, and the associated image should have an arrow indicating the direction of gaze, with a corresponding letter designation (Figure 2.2 a, b).

Figure 2.2 - Local species The local view may be limited by the line of breakage, if possible in the smallest size (Figure 2.2, a), or not limited (Figure 2.2, b). Additional views - images obtained on planes that are not parallel to the main projection planes. Additional views are performed in those cases if any part of the item cannot be shown on the main views without distorting the shape and size. An additional view is marked on the line with an “A” type inscription (Figure 2.3, a), and an arrow associated with an additional image of the subject is marked with an appropriate letter designation (Figure 2.3, a) indicating the direction of sight. When the additional view is located in a direct projection link with the corresponding image, the arrow and the inscription above the view are not applied (Figure 2.3, b). The additional view can be rotated while maintaining the position adopted for the item in the main image. At the same time, a sign (“Rotated”) is added to the inscription “A” (Figure 2.3, c). Basic, local and additional types are used to image the shape of the external surfaces of the object. The successful combination of them allows you to avoid the dashed lines, or reduce their number to a minimum. To reduce the number of images, it is allowed to display the necessary invisible parts of the surface with the help of dashed lines. However, identifying the shape of the internal surfaces of the subject with the help of dashed lines greatly complicates the reading of the outline, creates the prerequisites for its incorrect interpretation, complicates the size and symbols, therefore, their use should be limited and justified. To identify the internal (invisible) configuration of the item, apply conditional images - sections and sections. Figure 2.3 2.2 CutsThe section is the image of the object mentally dissected by one or several planes.. On a section showing what is located in the cutting plane and what is located behind it. 2.2.1 Classification of cutsDepending on the the number of cutting planes Sections are divided into (Figure 2.4):

Figure 2.4 - Classification of cuts The position of the cutting plane is shown on the main image with a thick open line (1,5 s, where s- thickness of the main line). The length of each stroke is from 8 to 20 mm. The direction of the view is shown by arrows perpendicular to the strokes. Arrows depict at a distance of 2-3 mm from the outer ends of the strokes. The name of the cutting plane is indicated by capital letters of the Russian alphabet. The letters are applied parallel to the horizontal lines of the main inscription, regardless of the position of the arrows (Figures 2.5, 2.6, 2.9, 2.10, 2.11). If, when making a simple section, which is in projection connection with the main image, the section plane coincides with the plane of symmetry, then the section plane is not drawn, and the section is not signed.

Figure 2.5 - Designations of cuts in the drawing

Figure 2.6 - A simple section: a) - frontal; b) - local Depending on the cutting plane positions relative to the horizontal plane of the projections, the sections are divided into:

Figure 2.7 a - model details "Crank"

Figure 2.7 b - Simple horizontal section Vertical the sections are called:

Figure 2.7 c - Simple frontal section

Figure 2.7 g - Simple profile section

Figure 2.8 - Inclined cut Challenging Sections are divided into:

Figure 2.9 - Complicated - Step cut

Figure 2.10 - Difficult - Broken incision Sections are called:

Sections that serve to clarify the device of an item only in certain, limited places are called by local .

Figure 2.11 a - Examples of cuts

Figure 2.11 b - Examples of cuts combined with species 2.2.2 Making cutsHorizontal, horizontal and profile cuts can be located at the site of the respective main species (Figure 2.11, a, b). A part of the species and a part of the corresponding section can be joined by separating them with a solid wavy line or a line with a break (Figure 2.11, b). It should not coincide with any other image lines. If half of the view and half of the section are joined, each of which is a symmetrical figure, then the separation line is the axis of symmetry (Figures 2.11, b; 2.12). It is impossible to combine half of the view with half of the section, if any image line coincides with the axial one (for example, ridge). In this case, the majority of the species is connected with the smaller part of the species, or most of the species with the smaller part of the species. It is allowed to separate the section and the type of fine-punched thin line that coincides with the trace of the plane of symmetry of not the whole subject, but only its part, if it represents the body of rotation. When half of the species is joined with half of the corresponding section, the right side of the vertical axis and the bottom of the horizontal one are located (Figure 2.12).

Figure 2.12

Figure 2.13 Local The sections are highlighted in the form of solid wavy lines. These lines should not coincide with any other image lines (Figure 2.13). Section shapes obtained by different cutting planes when performing complex Split, do not separate one from the other by any lines. A complex stepped section is placed on the site of the corresponding main view (Figure 2.9) or in any place of the drawing. For broken sections, the cutting planes are conventionally rotated to fit into one plane, while the direction of rotation may not coincide with the direction of gaze. If the combined planes turn out to be parallel to one of the main projection planes, the broken section is allowed to be placed in the place of the corresponding type (Figure 2.10). When the cutting plane is rotated, the elements of the object located behind it are drawn as they are projected onto the corresponding plane with which the combination is made. It is allowed to connect a stepped section with a broken line in the form of one complex section. 2.3 SectionsCross section the image of the figure, which is obtained when the object is thought to be intersected by the section plane, is called (Figure 2.14). On the cross section, only that which falls directly into the cutting plane is shown. The secant planes are chosen so as to obtain normal cross sections. Sections are divided into:

Not included in the section are divided into:

The removed sections are preferable and are allowed to be arranged in a gap between parts of the same type, along the trace of the section plane with a symmetrical figure of the section, anywhere on the field of rotation, as well as rotation (Figures 2.14, a, c; 2.15, b; 2.16, a; 2.17, a; 2.18, a). For the image of the trace of the section plane, the thick open line with the arrows indicating the direction of gaze is used on the image, and the cutting plane is designated by written letters of the Russian alphabet. The section is accompanied by an AA-type inscription (Figure 2.14). The ratio of the dimensions of the arrows and the breaks of the open line must correspond to Figure 2.14. The initial and final touch should not cross the contour of the image. The letter designations are given in alphabetical order without repetition and, as a rule, without permissions. The size of the font of letters should be larger than the size of the dimensional numbers approximately two times. The letter designation is parallel to the title block, regardless of the position of the section plane. In the general case, when the section is located on any free space in the drawing, the position of the trace of the section plane is depicted as above, and the section image is accompanied by an inscription corresponding to the name of the section plane (Figure 2.14, a; 2.15, b). In the cases shown in Figures: 2.14, b, c; 2.17, a, b; 2.18, a (superimposed sections; sections made in a type break; sections made on the continuation of the section of the section plane) - for symmetrical sections the trace of the cutting plane is not shown and the section is not accompanied by an inscription.

Figure 2.14 but

Figure 2.14 b

Figure 2.14 at For unbalanced sections , located in a gap, or superimposed, the trace of the section plane is depicted, but not accompanied by letters (Figure 2.16). The section is also not accompanied by the inscription. The contour of the removed section is made with a thick solid line (the main line), and the contour of the superimposed section with a thin solid line, while the contour of the view is not interrupted.

Figure 2.15

Figure 2.16

Figure 2.17 but,b

Figure 2.18 For several identical sections of the same item, the section lines are denoted by one letter and one section is scribed. If in this case the cutting planes are directed at different angles, then the “Rotated” sign is not applied (Figure 2.19).

|

|||||||||||||||||||

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners