Site sections

Editor's Choice:

- Expansion joints in buildings

- Shaber - what is it and its purpose

- Sharpening wood mills: manual work using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriki in architecture

- Surface scaling - metalwork

- Maximum load on a balcony slab: how much can a balcony withstand in a panel house?

- Projects: legend on drawings for water supply and sewage

- Marking and marking parts How to mark parts with curved contours

- Slotting Tools Slotting Tools

- Mortising tools mortising tools

Advertising

| The device of flights of stairs and platforms. Installation of flights of stairs and platforms: general information. Progress on installing sites and flights of stairs |

|

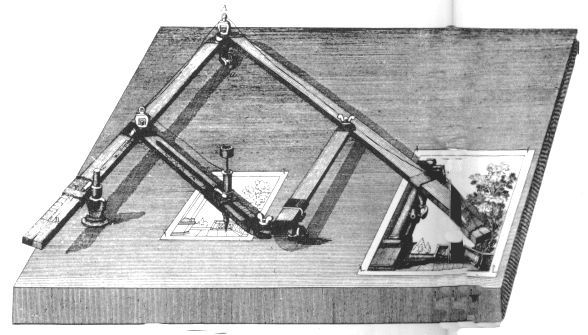

INSTALLATION OF STAIRS AND MARCHES Tools, fixtures, equipment: mounting belt (2 pcs.), Platform for a welder and installer (2 pcs.), Stairs for climbing to the next floor, steel mounting scrap (2 pcs.), Four-branch sling with two shortened branches, mortar shovel , a metal brush, a box with hand tools, a metal meter (2 pcs.), a container box with a solution, a trowel (2 pcs.), a bucket of water, a broom, a metal brush, a ladder to climb to the next floor, a template for reconciling the site , universal load gripping device, 2 m long wooden rail. The scheme of the organization of the workplace when installing stairwells and flights of stairs: 1 - assembly scrap, 2 - a box with hand tools, 3 - a platform for a welder and installer, 4 - a mortar shovel, 5 - a container box with a solution, 6 - flights of stairs, 7 - a template for aligning the site, 8 - a ladder for lifting to the next floor, 9 - mounted platform Preparation of the element for installation (Fig. 1) Rigger 1. Approaches the design lying in the warehouse and inspects it, checking the condition of the cladding, mounting loops and embedded parts. 2. If necessary, cleans the surface with a metal brush. 3. Gives a signal to the crane operator to submit to the design of the load gripping device 2. 4. Alternately leads the hooks of the slings 2 into the mounting loops and allows the slings to be pulled. 5. After checking the correctness of the sling, it moves to a safe area. 6. Instructs the crane operator to lift the structure 1 by 200 ... 300 mm from the surface. 7. Approaches the suspended element, once again checks the reliability of the slings and gives permission to supply the structure to the installation site. Preparation of the installation site for the landing, site installation (pic Installers 1st, 2nd 1. Lay out tools, equipment and accessories. 2. Then they roll up the platforms for the welder and installer 4 to the installation site of the landing on the wall and climb them (Fig. 2).

Fig. 1. The scheme of lifting the site: 1 - platform, 2 - universal load gripping device, 3 - rigging 3. Metal meters mark the installation site of the structure. one 4. The 1st installer checks the accuracy of the installation of the site according to the marking and, if there are deviations, gives the command to the 2nd installer to shift it in the desired direction. 5. The 2nd installer with the crowbar shifts the platform to the required distance. 6. Then he takes the template and rises to the previously installed platform, which is lower than the set (Fig. 4).

Fig. 4. Scheme of reconciliation of the landing: 1 - lower platform, 2 - 2nd installer, 3 - template for reconciling the site, 4 - 1st installer, 5 - installation site 7. The 1st installer rises to the mounted platform by a ladder. 8. The 2nd installer submits to the 1st installer one end of the template 3. 9. The installers simultaneously apply the template to the sites at two points: to the site adjacent to the support points on the wall panels and in the middle of the site.

Fig. 5. Layout of the landing: 1 - 2nd installer, 2 - stairs to the upper floor, 3 - sling, 4 - 1st installer, 5 - site 10. In case of deviations, the 1st installer crowbar shifts the site in the right direction. 11. The installers again check the position of the site with a template. 12. The 1st installer gives a signal to the crane operator to loosen the slings 3 (Fig. 5). 13. The 2nd installer rises to the installed site and removes the hooks of the sling from the mounting loops of the structure. 14. The 1st installer allows the crane operator to lift the slings and take them to the side. 15. The 2nd installer at the time of lifting the slings ensures that his hooks do not catch on the hinges and projections of the structure. Preparation of the installation site for the flight of stairs (Fig. 6), Installers 1st, 2nd 1. The 2nd installer with a shovel delivers the solution from the container box to the place of support of the upper and lower ends of the flight of stairs. 2. The 1st installer trowels 2 to level the solution with a uniform layer on the upper platform. 3. Then level the solution on the lower platform. Installation of a flight of stairs (Fig. 7 ... 9) Installers 1st, 2nd 1. The 1st installer, being on the upper landing, gives a signal to the crane operator to file a flight of stairs 3 to the installation site (Fig. 7). 2. Then it takes a march at a height of 200 ... 300 mm from the level of the upper platform (relative to its end of the march) and orientates in the desired direction. 3. After it gives permission to the crane operator to continue lowering the structure, keeping it from swaying. 4. When the element is lowered to a height of 300 ... 400 mm from the level of the lower platform, it gives the crane operator a signal to stop lowering. 5. Installers press the march against the wall panel, the 1st installer gives a signal to the crane operator to slowly lower it. 6. First, the 2nd installer places the lower end of the march on the mortar bed, and then the 1st installer puts the upper one. 7. Installers determine the accuracy of the installation by leaning the wooden rail against the surface of the site and one step of the march. With a metal ruler, the gap between the bottom of the rail and the plane of the installed structures is measured. If the gap does not exceed 5 mm, then the installation is considered complete. As you gain the skill to determine installation accuracy visually, the need for rail is no longer needed. https://pandia.ru/text/77/506/images/image007_6.jpg "width =" 510 height = 279 "height =" 279 "\u003e Fig. 7. The scheme of installation of the flight of stairs: 1 - 2nd installer, 2 - four-branch line with two shortened branches, 3 - installed flight of stairs, 4 - 1st installer

Fig. 8. Schematic reconciliation of the flight of stairs 1,5 - assembly scrap, 2 - 2nd installer, 3 - flight of stairs, 4 - 1st installer 8. If there are large deviations, the installers with the crowbars correct the position of the march and re-check (Fig. 8). 9. The 1st installer gives a signal to the crane operator to loosen the slings (Fig. 9). 10. Installers release the sling hooks from the mounting loops. 11. The 1st installer permits the crane operator to lift the slings. 12. The 2nd installer holds the slings while lifting.

Fig. 9: Layout of a flight of stairs 1 - 2nd installer, 2 - 1st installer Electronic text of the document prepared by Codex CJSC and verified against materials provided (VITU) Stairs and landings are one of the most important elements of many residential buildings. They have many important features. Firstly, they allow you to climb or go down. Secondly, the stairs give the interior design a unique look, with their help you can refine any room.

A march is a series of steps that connect two landings or two floors. They can be oblique, straight and curved depending on their shape. If the staircase has several marches, then the lowest one is called the starting one, and the upper one is called the weekend. If you draw a line in the middle of the march (shoot line), then it should be located no closer than 30 cm to the edge of the span, respectively, the minimum width of the stairs should be at least 60 cm. If the flight of stairs is not next to the wall, then it should be designed for two-way movement and equipped with handrails on both sides. A staircase is a horizontal section located between two flights. They can be quadrangular or polygonal, as well as arbitrary shape. Their sizes are designed based on the human step. Moreover, their length corresponds to the span, and the width is equal to the width of the march. If marches are located perpendicular to each other, then the site usually has a square shape, but if they are parallel, then it is rectangular or semicircular.

The functionality of the sites and marches is preserved only if they are performed in compliance with all building codes and rules. In addition, their installation must comply with safety precautions. Therefore, it is necessary to pay a lot of attention and observe all the rules for their installation. As a rule, the installation of marches and platforms is carried out using a crane, which gives confidence that the installed stairs will be strong and durable, with high performance and compliance with all modern building requirements. When installing stairs, it is necessary to take into account the layout of buildings and the designed features of the premises where the flights of stairs will be located. Progress on installing sites and flights of stairsWooden structures can be installed without using special construction equipment, since wooden elements can always be changed in size, and their installation is not particularly difficult. It is much more difficult to install concrete structures. Installation is usually carried out in several stages. Back to the table of contents Minimum size deviationsThe first step in the installation of platforms and flights of stairs is to prepare the place for their future location. As practice shows, both platforms and marches are installed parallel to the process of erecting the building itself, that is, when the construction of the next floor is completed, all the stairs on this floor should already be installed. Accordingly, before the start of construction, it is necessary to determine the size and exact placement of future spans.

The most important thing is to observe the dimensions of the finished products. The difference between the finished and planned sizes should be minimal. So, the length of the landing should be no more than eight millimeters more than the design. At the same time, the deviation in the smaller direction (less than the design dimensions) cannot be more than five millimeters. The width of the landing, similarly to the length, cannot exceed or be less than the design width by more than five millimeters. The same applies to spans, for them a deviation of five millimeters both in length and in width is allowed. It should be remembered that following the project is not only a guarantee of the durability and reliability of the staircase construction, but also the safety of the people who will use this staircase. It is necessary to carefully and carefully approach the direct installation process. Before starting installation work, a site should be broken down directly at the installation site. Marks made must be transferred to the walls using a flexible level. After the marks, the coincidence of the marks of the future nests is checked, in which the supporting parts of the stairs will be installed. Back to the table of contents Installation of sites

Installation of sites is the second stage of work. To begin with, a significant layer of the solution is applied to the lower plane of the nest, which was calibrated at the previous stage. Thus, the socket is prepared for direct installation. After laying the solution using the mounting mechanism, staircases are fed. They are fixed in the wall blocks with support ends, which are inserted into the prepared nests and fixed with a solution. After the installation of the supporting ends, the entire site is checked by the level for correct installation horizontally. After the site is installed and leveled, the compliance of the location of the installed site with respect to the designed places is checked. If the deviation is greater than the standards, then the site is dismantled and reinstalled. If the location of the site coincides with the design, then the installation of the next site. Back to the table of contents Preparing for the installation of flights of stairsWhen all the landings are mounted and leveled, the third stage of work begins - the installation of flights of stairs. Like stairwells, they must be installed in compliance with all building codes and safety regulations. At the same time, they must accurately rely on previously established sites and be firmly fixed. Before starting the installation of flights of stairs, it is necessary to pay attention to the correspondence of the configuration of their cuts to the prepared profiles, which will be a support for them. Verification is carried out by specialized inventory of design templates. In addition, a breakdown of the installed sites with marks on the wall blocks is carried out.

After the preparatory work is completed, the marches are directly installed using the mounting mechanism. Future flights of stairs are hung on hooks using traverses (special supporting devices), which have balancer slings for this. The length of the lines can be adjusted, which makes it possible to quickly and efficiently install stairwells to prepared places. First of all, the upper end of the march is lifted to provide reliable support for the structure with the lower end. If both ends of the span are raised simultaneously, then problems may arise associated with the rotation of the raised structure, which can lead to jamming of the flight of stairs between the platforms. In addition, you can not install the structure if it rests only on the upper end, as this can lead to its disruption and the collapse of the entire structure. Safety during installation is strictly regulated. When installing the march, workers should be at the same time at the upper and lower ends to simultaneously fix the entire structure, which will help to avoid unnecessary problems. Operations and controls

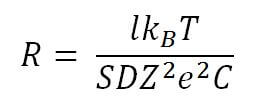

Technical requirements SNiP 3.03.01-87 pp. 3.6, 3.7, tab. 12 Limit deviations: Steps from the horizontal - 2 mm; Protective grilles from the vertical - 3 mm; Marks of the top of the landing from the design - 5 mm; Stair areas from the horizontal - 5 mm; From symmetry (half the difference in the depth of support of the ends of the site) in the direction of the span to be blocked with a length of the platform up to 4 m - 5 mm; Dimensions of the depth of support of the sites in the direction of the overlapping span - according to the project. Not allowed: The use of a solution, the setting process of which has already begun; restoration of the plasticity of the solution by adding water. GOST 9818-85 *. Marches and stairs are reinforced concrete. Technical conditions GOST 13015-2003. Reinforced concrete and concrete products for construction. General specifications. Rules for acceptance, labeling, transportation and storage. The maximum deviations of the sizes of marches and platforms from those specified in the working drawings should not exceed the following values: In length for marches and platforms up to 4000 mm long - ± 5 mm; The same, with a length of over 4000 mm - ± 6 mm; Thickness - ± 3 mm; Width - ± 5 mm; By the size of the ribs, shelves, protrusions, holes and channels - ± 5; According to the position of the protrusions, recesses and holes - ± 5 mm. Deviations from the design position of steel embedded products shall not exceed, mm: In the surface plane for embedded products with sizes up to 100 mm - 5; The same for embedded products in the size of St. 100 mm - 10; From the surface plane - 3. Limit deviations of the sizes of laid on treads should not exceed, mm: In length - ± 5; In width - ± 3; In thickness - ± 2. Deviations from the straightness of the profile of the front surface should not exceed, mm: The steps of the march, platforms or overhead treads up to 2500 mm long in the area of 1000 mm - 2; St marches or sites 2500 mm to 4000 mm over the entire length - ± 3; The same, the length of St. 4000 mm over the entire length - ± 4. The quality of surfaces and the appearance of structures must meet the requirements given in the table. Marches and staircases placed for installation shall not have: Grease and rust spots on the front surface; Cracks, with the exception of shrinkage and other surface technological cracks on the lower and end surfaces of the elements, the width of which should not exceed 0.2 mm; The influx of concrete on the open surfaces of steel embedded products and mounting loops. Work Instructions SNiP 3.03.01-87 pp. 3.3, 3.5 Installation of flights of stairs and platforms is allowed only after the acceptance of supporting elements, including a geodetic check of compliance with their planned and high-altitude position with the preparation of a geodetic executive scheme. In order to ensure the stability of the stairwell and its connection with the floor drive, the installation of stair flights is allowed only after the complete filling of adjacent spans with floor slabs. Before lifting each flight of stairs, it is necessary to verify compliance with its design mark, to clean the supporting surfaces of crossbars, stiffness diaphragms and flights of stairs from debris, dirt, snow and ice. Stair flights are fed to the installation site in the design position and laid on a cement mortar layer up to 30 mm thick. The brand of the solution should be indicated in the design. The mobility of the solution should be 5-7 mm. Marching staircase construction can both include platforms and consist only of a march. The latter is possible if the span is small. In the case when the number of steps on the march exceeds 16, the construction of a horizontal section is mandatory.

Building standards for direct marching stairs. A march is a sequence of steps arranged in a straight line, oblique, and curved. A direct march is a structure in which steps are erected in a straight line.

The landing is a horizontal section between the marches. Dimensions and shape are determined taking into account the average length of a human step.

Installation of stairs in a residential building: requirementsFor multi-story residential and office buildings, concrete or reinforced concrete structures are used. Work on their installation is carried out using special equipment. Before installation, a product quality check is carried out: both visual and measuring. If garbage, dirt, ice and the like are detected, cleaning work should be carried out. If the geometric parameters of the design do not match, the product is not accepted and installation is not carried out.

According to SNiP, the permissible deviations are as follows:

Deviations in the sizes of elements are from 3 mm for thickness, up to 5 mm for length. In this case, cracks, sagging, spots of rust or grease on the surface of metal elements are not allowed. DIY staircase installationThe manufacture and installation of a staircase in a private house is often done independently, especially if the owner has experience with wood, or even metal. This option is feasible in the case when the weight of the product does not reach half-tones. The construction of a concrete staircase will require a different technology. Since it is impossible to make and install a flight of stairs without construction equipment, a different method is used: formwork is made, that is, a wooden model, and then concrete is poured into it. Not only apartment buildings, but also private buildings often have more than one floor of height. To move between levels requires the installation of flights of stairs and platforms. This article gives basic ideas about the structural elements of stairs, their characteristics and GOST standards.

Elements of staircase constructionWhen choosing a transitional structure between floors, the layman most often gives priority to the beauty and aesthetics of the stair elements, however, we should not forget that the device of the staircase should first of all provide regulated by GOST utilitarian requirements, among which safety is paramount.

Staircase Design ElementsThe following are the definitions of the main staircase elements:

Materials for stairsDepending on what materials the staircase is made of, both the price of the product and its characteristics depend.

Main characteristics of marches and sitesAccording to GOST, the slope of the march is 1: 2 - 1: 1.75 ratio of height to the length of the step, for auxiliary - no steeper than 1: 1.25. The steps in the march are made the same, comfortable for walking, their number is not less than three and not more than 18. The most common marches with 10 - 13 steps - this number is considered the most convenient when climbing or descending. The width of the steps should ensure the production of a full foot (at least 250 mm), the height should be in the range of 130-200 mm. The fencing of platforms and marches is performed with a height of 0.9 m. The width of marches according to GOST is not less than 800-1000 mm, and the width of the platform is not less than the same size chosen for the march. Preparation for installationDepending on the material, the work done for the construction of the staircase differs. They can be divided into two stages: the preparation of elements and installation.

Based on the technical documentation, elements of the required dimensions are purchased or manufactured: kosouri, steps, platforms and fences. They mark up the place of their fasteners and, if necessary, pre-assembly. At this stage it is important to comply with the requirements of GOST for the size and configuration of stairs. Installation of basic elements

The fasteners of the staircase elements also depend on the type of material, which determine what characteristics kosour and other components should have. Invariably one thing - the installation should provide a rigid fixation of the staircases and platforms to the bearing walls. Such is the price of security. Installation of fencesFencing marches and platforms - one of the important components of the stairs. Its primary task is to ensure safety (to protect against a possible fall) and ease of movement (to serve as a support when climbing or descending). Main elements:

Requirements for stair railings are governed by the standards of GOST, according to which their height for internal stairs is at least 90 centimeters. Fences must be free of sharp corners and protrusions and have a refractory treatment.

Special requirements are imposed on stairs in institutions where children are located (schools or kindergartens). Here, the execution in accordance with GOST should be such as to protect the little ones: it is necessary to install additional handrails with a height of 50 centimeters. The maximum clearance between the balusters is 10 cm. If there are children in a private house, these GOST requirements should be observed when building a staircase fence. There are various methods of fastening balusters fences to marches and platforms: welding, concreting, fixing with screws - for each material there is its own, most correct, solution. The main condition: the design of the stairs must be safe. The collected information describes the main milestones of the staircase. Those who wish to study the “narrow” questions in more detail, we invite you to find answers on our Internet resource or leave a comment with your wishes on the disclosure of the topic of interest. For example, more details about the requirements are already written in the corresponding article. |

||||||||||||||||||

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners