Site sections

Editor's Choice:

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

- Surface grit - tooling work

- Maximum load on the balcony slab: how much can a balcony withstand in a panel house?

- Projects: symbols on drawings for water supply and sewage

- Marking and marking details How to mark the details with curved contours

- Tools for slotting Tools for slotting

- Tools for chiseling Slotting tools

Advertising

| Engraving copy milling machine with pantograph 6461. DIY pantograph for router. Blueprints. The process of creating the machine with your own hands |

|

In the modern world, in the community of people who love to do things with their own hands and at the same time do not shy away from technology, such a thing as a desktop CNC machine is extremely popular. Although these devices have become quite affordable, they are still expensive. The cheapest Chinese version, today, will cost you 700-800 American money and it probably will not work out of the box right away, but will require an effort to bring it to mind. The manufacture of a CNC machine can cost less on its own, but usually requires access to various types of woodworking and metalworking equipment and the ability to use it to produce parts with high precision. But people are always looking for ways to achieve goals with affordable means.

The classic pantograph consists of two vertices, in one of which is fixed a pen-pointer, with the help of which a copied drawing is circled. In the second, a writing instrument is fixed, which, through a system of levers and hinges, repeats the movements of the first vertex by drawing a copy on the second sheet. Often in the pantographs incorporated the function of scaling the original image. A simple and ingenious idea. Now, and how to copy a certain volume object? To do this, add a Z-coordinate to the pantograph and replace the pencil with a drill, or rather a high-speed spindle, and we will get a 3D pantograph.

Machines for copying wooden products on such a principle are produced for example by the American company Gemini and only the prices for them are such that with this money you can buy a good CNC machine from China. Therefore, what the DIY community has achieved in this area is more interesting.

Frank Ford makes acoustic guitars. In doing so, he has to make many identical guitar parts, such as string holders. Charter to do it manually, but not wanting to bother with the purchase and adjustment of the CNC, he made a duplicator for himself. Because he was important high accuracy of copying, his tool is made entirely of metal. The stylus is removed and the spindle is fixed on a common frame that moves only along the Z axis. The X and Y axes are moved using the table on which the workpieces are fixed. Another original in its design is that it uses a pneumatic drive operating at 40,000 rpm as a spindle. Nevertheless, even though it is a self-made, but still expensive version of the 3D pantograph. There are cheaper.

For example Adran (Adran), dreaming about his own CNC machine, but not having the means to do so. He designed himself a duplicator from a Dremel drill, three metal guides and wooden slats of standard sizes from the store. A standard screwdriver is used as a probe. Its design can be easily repeated, because He posted the drawings and all the manufacturing steps on the Instructables website.

However, the manual drill, not the most successful tool for such work, the speed of removal of material from her is too small. Here Matthias Wandel from Canada used a hand mill in his 3D pantograph. What gave him enough power to quickly copy objects in the tree. As an example of working with such a duplicator, here is his video, where he makes a copy of the form of an old dial telephone (English). Its design can also be repeated, because He posted the blueprints and manufacturing instructions on his website Woodgears.ca. Even if you are not friends with English, there you can easily understand the whole process through numerous photographs. If the topic of 3D pantographs interested you, then on English-language resources examples of such devices can be found by tags: carving duplicator, duplicarver, pantorouter. The equipment of copy type is used in cases when it is necessary to carry out the manufacture of parts on a specific pattern within a small batch. In some cases, a copy-milling machine is used under high-volume production conditions, like a CNC type. This is due to the fact that the machine in question is capable of creating products whose shape most closely matches the original sample, just like CNC machines, the movement of the milling cutter is automatically set. The main feature that has a copy-milling machine - high speed processing. PurposeOften a copy milling machine is used to perform processing on the volume and on the plane, its work is similar to the options on which the CNC system is installed. At the same time, special models allow processing on the tree by volume, when a three-dimensional model is used as a copier. In the woodworking industry, processing by volume allows:

The considered machine for wood is often used in the production of furniture. Many decorative pieces that have a complex shape are created using a similar machine tool. Principle of operationThe possibility of a significant acceleration of the production process of complex products is due to the peculiarities of the work that the copy milling machine has. As with metal processing, a cutting tool called a “milling cutter” is used in woodworking. The main points of work include:

The copy milling machine works as follows: a sample of various types is installed, a tracking device is brought to it, which, through a certain type of connection, transfers the necessary force to the cutting tool. Classification

Also machines for wood vary in the level of automation of the production process. The CNC is installed in this case quite rarely, since the template processing method does not require a Numerical Software Control system to indicate the path of the cutting tool. Making a machine by yourselfThere is a huge number of machines on the copy-type tree, which are known as a pantograph, have a CNC system (a universal version that allows processing by copy or program). However, not everyone can acquire such equipment, which is connected with its very high cost. The addition of CNC makes the equipment available only for large manufacturers, when the payback period of the equipment is less than 5 years. That is why many are wondering - how to make a machine with your own hands? Before committing to work, it is worth remembering that self-made machine tools are significantly inferior to industrial models. At the same time, it is impossible to make a CNC option yourself. Many people also note that it is also very difficult to convert an ordinary milling version into a do-it-yourself copier, and it is often easier to start from scratch. It is easy to make a pantograph yourself, but there are still some difficulties in this process.

There are many schemes in which you can create a copy milling machine with your own hands. Typical option, as a rule, consists of the following elements:

To implement the procedure for changing the cutting mode, the height of the table is changed, the head with the cutter is electrically driven, which drives the cutting tool, often including a transmission mechanism to change the speed in the system. The pantograph itself can be made as follows:

When creating a machine with your own hands, it should be noted that many details may have flaws and discrepancy sizes. This situation is associated with vibration and ground tremor, which is difficult to avoid. While changing the direction of movement of the cutter, errors are also possible. Due to the internal stress of the wood workpiece, the workpiece can be bent. Therefore, it is recommended to create such equipment only for narrow-profile production, when the machine will be designed to create one piece. It is almost impossible to avoid the problems under consideration, however, subject to processing the same part, a gradual improvement in the design is possible. Nowadays, there is often a need to create a copy of some object. For these purposes, modern enterprises use special copying machines, the shape of which most closely matches the desired sample. Such milling copiers make it possible to manufacture parts of various complexity and shape. In this case, the equipment must, in a short time, process and manufacture the required element. Factory or homemade machine?The modern market offers to purchase milling and copying machines of various levels of complexity and design. But it is not always possible to make such a purchase, and the cost of such equipment for wood is quite tangible. That is why folk craftsmen often have a question about a self-made milling and copying machine, the production of which is less expensive compared to self-assembly. Now, in the case of the availability of relevant drawings, materials and skills, such equipment can also be made by hand. It is clear that such a variety of home-made equipment cannot compete with factory-made equipment in terms of its parameters and usability. But with a reliable version with a machine-made with their own hands, you can make enough high-quality copies of certain objects made of wood.

That is why you can make a copying machine on wood with your own hands only “from scratch”, using the systems of the electric motor and a special cartridge in which the mill will be engaged in processing the workpiece. What is a copy milling machine?

The constructions of self-made equipment of such purpose exist in our time quite a lot depending on the drawing used and the tasks that will be performed on this technique. A typical tree copier consists of the following basic elements:

The milling head must be equipped with a transmission mechanism with an electric motor, which can provide several speeds of a homemade milling and copying machine for wood. A large number of national craftsmen, who made such a machine by their own hands according to the drawings, note that as a result of copying the finished part has a sufficient number of flaws. They appear during the change of direction of the cutter, shake and vibrations of the whole structure. In addition, inconsistencies also occur due to the curvature of the workpiece, which occurs when the internal stress increases as a result of the production of a wooden piece.

Features self-create copier

Thus, the copy milling machines in the manufacture of their own hands must be optimized for the processing of specific parts that will be produced on it. Otherwise, there may be various side effects that are often very difficult to correct. Quite an important factor that must be taken into account when hand-made production of the machine-copier is its size and total weight. The larger products will be processed on it, the more massive the whole structure should be. This will allow the equipment to absorb vibrations that occur during the operation of the cutter. The guide axes must be made so that they have a significant margin of safety, without bending under increased loads. The optimal properties of the copy-milling machine for wood in the manufacture of his own hands can be chosen empirically, since it depends on the design of the equipment and the purposes for which it will be used. What you need to consider when developing a machine?

Also the power of the electric motor necessary for high-quality work, which provides the cutter rotation, depends on the parts produced and copied on the machine. But in most cases, 150-220 W of a DC motor can be sufficient for processing wooden parts. To ensure maximum accuracy of copying parts, the device holding the router and copying probe should be as securely fastened as possible. At the same time, their planes, along with the height above the working surface, must coincide in full.

Thus, it is not very difficult to make a copying machine for the manufacture of various parts from wood, so many can handle this work. But we must remember that in the case of the manufacture of such equipment with their own hands, it is suitable only for the production of products of a particular type. Otherwise, only modern factory-made universal equipment will do.

Information about the manufacturer of the engraving copy-milling machine 6L463Manufacturer of engraving copy milling machine 6L463 - Lviv factory of milling machines, LZFSfounded in 1952. 6L463 engraving copying and milling machine with a pantograph. Purpose, scopeThe machine is designed to perform engraving and small copying and milling works in the contour mode. The machine can engrave inscriptions and patterns on stamps, tablets, boards, panels, inscriptions on limbs, rulers, as well as the milling of shallow molds for plastics, rubber, etc. The ability to work on a machine using a counter pattern allows using a flat-plate copier to engrave various inscriptions and patterns on spatially complex surfaces. Main characteristics of the engraving copy milling machine 6L463Manufacturer: Lviv plant of milling machines LZFS.

Fixing the spindle motionless using a special bracket, you can perform milling work on the machine by moving the product table manually. Copying movement on the machine is carried out manually by moving the tracer groping device along the contour of the copier. The machine can be equipped with a wide range of devices and accessories, expanding its technological capabilities: for building arcs, circles, and ovals, for fixing plates for engraving, dividing device, vise, swivel vise, tilt-swivel table, alphabetic and numeric templates, sharpening engraving cutters, etc. Work on the counter pattern using a flat-plate copier allows engraving of various inscriptions and patterns on spatially complex surfaces. Copying movement on the machine is carried out manually by moving the tracer groping device along the contour of the copier. The machine can be used in mechanical, mechanical assembly and tool shops of machine-building enterprises. Accuracy class H according to GOST 8-77. The roughness of the treated surface R and 2.5 microns. The average LA sound level should not exceed 71 dBA.

Overall dimensions of the working space of the machine 6L463 General view of the copy-milling engraving machine 6Л463

Photos of the engraving machine 6l463

Photo milling machine on the base 6l463

Photos of the engraving machine 6l463

The location of the components of the engraving machine 6l463 The list of components of the engraving machine 6L463

The location of the controls engraving machine 6L463

The location of the controls engraving machine 6L463 The list of controls engraving machine 6L463

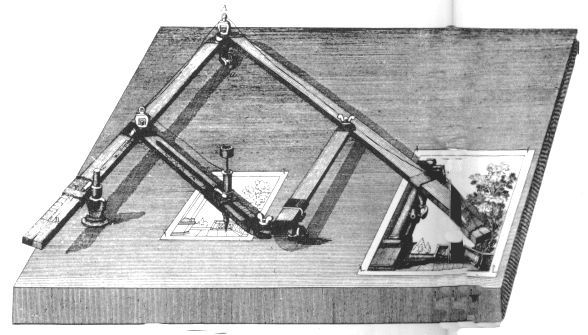

Kinematic diagram of the engraving machine 6l463 Description of the nodes of the engraving machine 6L463The engraving copy-milling machine with a pantograph model 6L463 is made in the form of a single-column construction with a vertical spindle axis and horizontal arrangement of the product and copier tables. The bed is equipped with vertical guides, which moves the console, carrying the desktop of the machine. Regarding the console, the desktop can move in the longitudinal and transverse directions. A carriage is installed on the upper horizontal guides of the bed, carrying a pantograph and a copier table. The pantograph of the machine is made in the form of light levers and serves only to transfer movement from the tracer to the spindle. The spindle of the machine is mounted in a special bracket connected by means of levers to the frame. The spindle motor is driven by an electric motor and a belt drive. Changing the speed of rotation of the spindle is made using stepped pulleys. The overall layout and principle of operation of the machine 6L463The layout of the machine is characterized by a vertical spindle arrangement and a horizontal arrangement of the working surfaces of the tables. Machine knots are mounted on a rigid bed. On the vertical guides of the bed moves the console, carrying on the slide and the table products. On the horizontal guides of the bed moves the stand of the pantograph. Suspension and spindle drive are fixed on the frame. The workpiece is fixed on the table of the product, and the copier, which is being processed, is fixed on the table of the copier. Forming movements are movements of the pantograph. Moving tables - installation. BedThe bed and the base are the main body parts on which the machine components are mounted. On the left wall of the bed there are vertical guides along which the console moves with the product table. On the rear wall of the frame is installed bracket that holds the spindle arms and drive. In addition, a drive motor is mounted on the back wall, and electrical equipment is mounted in a niche. Copier tableCopier table 10 (Figure 10) is designed to install the copiers, which are processed. The copier table is mounted on the pantograph stand. The rotation of the table around the vertical axis is carried out manually. Setting the value of the angle of rotation of the table of the copier is carried out on the limb, fixing - handle. The copier table is provided with dovetail grooves, which serve to set the font. In addition, it has T-shaped grooves that can be used to install various fixtures. The stand together with the copier table and the pantograph can move along the horizontal guides of the frame, which allows you to install the spindle within the plane of the table of the product at different copying scales. Fixing the rack is carried out with two bolts. PantographThe pantograph (Fig.10) performs a copying movement on the machine. Copying using a pantograph (articulated parallelogram) is built on the principle of geometric similarity of triangles and is carried out according to the scheme below;

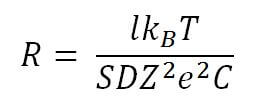

Pantograph of the engraving machine 6l463 The copying movement on the machine is carried out by a hinged four-stage pantograph (Fig. 10). Using carriages 43, 46 with dovetail grooves, the pantograph is connected to the spindle body and the carriage 47. The pantograph articulated joints and the suspension of the carriages 43, 46 are assembled on preload-loaded radial bearings, which increases the pantograph’s accuracy and accuracy. . The change in the gear ratio of the pantograph (copy scale) is made by moving the carriages along the shoulders 51, 52 of the pantograph, on which divisions are applied. Tracer (groping finger) 48 slides in the hole of the head and with the help of a spring pressed against the template. Tren-ser, depending on the height of the template, is set at a different height from the plane of the copier table. The copier table 49 is installed on the plane of the carriage 47. With respect to the carriage, the table can be rotated at any angle within ± 30 °, or turned to 90. The table is provided with dovetail grooves, which serve to set the font. In addition, it has T-shaped grooves that can be used to install various fixtures. The carriage together with the pantograph and the copier table can be installed in different positions on the frame, moving along its upper guides. This allows you to install the spindle within the plane of the table of the product at different scales of copying. Adjustment, adjustment of the engraving machine 6l463Getting started on the machine is necessary 1. Set the copying scale: for this, it is necessary to squeeze the screws 53 (Fig.10) of the mounting of the carriages to the pantograph and set both risks so that they coincide with the corresponding scale risks applied on the shoulders 51, 52 of the pantograph and clamp both screws 53. To obtain a scale copying, not specified on the shoulders, it is necessary to use the formula: x = 300- (300 / M); y = 107.5 (M-1) / (M = 1) where M - copy scale (ratio of copier size to part size). x - the distance from the risks corresponding to the scale of copying 1: 1 on the shoulder 52 to the risks on the movable carriage 43. at - the distance from the risks corresponding to the scale of copying 1: 1 on the shoulder 51 to the risks on the carriage 46. Example: It is necessary to obtain a scale of 1: 1.2 reduction. x = 300 - 300 / 1.2 = 50 mm Therefore, we postpone the 50 mm segment from the mark “1” on the shoulder 52 and set the carriage risk at this point. = 107.5 (M-1) / (M + 1) = 107.5 (1.2 -1) / (1.2 + 1) = 9.77 mm In the same way, we set aside from the “1” mark on the right shoulder 51 segments of 9.77 mm and set carriage 46 at this point at risk. So that the tracer does not go beyond the copier's table when the copy scale is changed, the latter can be rotated around an axis, within ± 30 °. If necessary, the copier table can be rotated 90 °. To do this, unscrew the nut 50 and raise the table so that the pin comes out of the carriage hole. Then, rotate the table 90 ° and put everything in reverse order. 2. On the copier table, set and clamp the template, and on the product table the part blank. 2. Set and clamp the template on the copier table, and a part blank on the product table. 3. Insert the cutting tool into the spindle. When engraving works, it is necessary to provide a certain pressure of the tracer (groping finger) on the template. This is achieved by installing the tracer at the required height. 4. Place the part on the product table and set it relative to the cutting tool. Installation of the workpiece is made by moving the product table in the longitudinal and transverse directions. Rough installation of the workpiece height is also made by moving the table product. Fine adjustment of the depth of processing is carried out by the spindle handle. 5. The machining modes (cutting speed, speed, feed) are set in each case and depending on the material being processed and the tool material. Product tableThe table of the product (fig. 11) is intended for fastening the processed parts on it. On the table can also be installed vise or rotary table. The product table can be moved manually in three mutually perpendicular directions.

Electric circuit of the engraving machine 6l463

6L463 engraving copying and milling machine with a pantograph. The video.Technical characteristics of the engraving machine 6L463

|

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners

Creating a drawing machine for wood copying and designing it, you must do everything depending on the parts that will be made on it. So, in order to mill long workpieces or to perform engraving works, a completely different way of securing workpieces and the type of desktop are required.

Creating a drawing machine for wood copying and designing it, you must do everything depending on the parts that will be made on it. So, in order to mill long workpieces or to perform engraving works, a completely different way of securing workpieces and the type of desktop are required.