Site sections

Editor's Choice:

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

- Surface grit - tooling work

- Maximum load on the balcony slab: how much can a balcony withstand in a panel house?

- Projects: symbols on drawings for water supply and sewage

- Marking and marking details How to mark the details with curved contours

- Tools for slotting Tools for slotting

- Tools for chiseling Slotting tools

Advertising

| How to make a standing seam. Installation of a faltsevy roof the hands: the step-by-step instruction. Installation of self-snap folded roof |

|

Actual, stylish and reliable roofing material, which is perfectly combined with various architectural styles. Thanks to the classic lines, this material will appeal to even the most conservative individuals. The main feature of the double standing seam is its versatility, not only because of its appearance, but also its technical characteristics and methods of fastening. This roofing material is suitable for sloping roofs and comes in a wide color palette. Specifications- * The cost of a double standing seam is calculated from the width of 625 mm (width of the workpiece) Fold seam and its typesA variety of seam seam guarantees the quality of the roof, its tightness and strength. Double standing seam is one of the most reliable, representing a longitudinal connection between adjacent seam paintings. The edge of the seam has a double bend. There is very little chance that water will somehow penetrate the seam, or the steel sheets will start to diverge over time. In this case, the fold can be rolled up either manually using special tools, or with the help of a folding machine. Clickfaltz is also very durable. Two pictures fasten with each other without the use of special tools. This saves a lot of time installing a folded roof. At faltsevy roofs a huge variation in price. Since the seam is not a material, but a technology. The material can be any - budget (galvanized), elite (copper), intermediate options. Consider what it is, profitable or unprofitable, what is the price per m2 of folding roof and how much it justifies itself. What is the fold?Fold is the connection of two sheets of metal, in which the edges are bent together in the same direction once (single fold) or twice (double). Double fold is more reliable and more tight, at all critical places (ridge, knots) perform it. The seam is formed in two steps: bending of the fold (if you work with sheet / roll material, and not with the finished picture) and crimp. The electric machine performs everything in one go.

Two or more sheets that connect on the ground and as such are raised to the roof are called a painting. Pictures are also called blanks with already curved edges. Some materials (galvanized, copper) are not sold in sheets, but in rolls: on a small roof, the picture may not have a single fold, the slope is covered with a whole stripe along the entire length. Locks will only be on the combination of the paintings between themselves. The fold can be standing or lying down (the lock is bent parallel to the sheet). Lying horizontal stripes connect the metal, the castle looks down the line of the weir. Perpendicular to the ridge (along the slope) make standing. There are also paintings with self-snap folds, they are connected to each other on the principle of the groove / crest.

Advantages and disadvantages of seam roofsPluses of a faltsevy roof:

Durability and cost can not be attributed to the advantages or disadvantages: they depend on the material. The more expensive the material, the more durable the roof: simple galvanization serves no more than 10-15 years, copper and zinc-titanium - more than half a century. They look the most elegant. Related ArticlesBasic rules for folding roofingYou can lay the roof on a continuous or sparse crate. In the second case, it is necessary to carefully observe the design step so that the coating does not sag. For the manufacture of sparse crates used:

If the crate is continuous, a vapor diffusion film is placed on top of it, directly under the coating. If sparse - then under it.

In the presence of insulation the structure of the cake is:

Our workThe price of metal for a faltsevy roofEstimated cost of material in Moscow:

Prices are for sheet and roll materials. Metal for a faltsevy roof can be released in the form of preparations with already bent edge. In this case, the price is not much higher. But the cost depends strongly on the manufacturer. 400-600 rubles for steel with polymer coating is the price of Russian brands. Imported more than 2 times. For example, paintings with Ruukki self-latching folds from polyester cost from 900 rubles per square, pural - from a thousand. It should be noted that the acquisition of expensive metals on the roof justifies itself: they are almost eternal, because they are not afraid of corrosion. The interaction with air and water produces a patina on the surface. It does not reduce the strength of the material (like, say, iron oxide), but on the contrary, it prolongs: the patina layer reliably protects the sheets from corrosion. And it looks noble. As for steel roofs - they, alas, do not last forever. In simple galvanizing, the resistance to external factors decreases as the zinc is washed off.

To extend the service life, the roof is regularly painted with oil paint (at least once every 2-3 years). Non-galvanized metal on the roofs (and generally for street work) cannot be used. Polymer-coated steel is safer than simple galvanizing, but the coating itself is very capricious. It is easy to scratch it during installation, and if you do not immediately paint over the scratch with polymer paint, corrosion will begin to develop at the site of damage. For comparison, other popular roofing coatings should be mentioned. Metal tiles on average cost about 300 rubles per square, the service life - up to half a century.

It also has a polymer coating, but there are advantages over the folded roof:

Flexible tiles also cost about 300 rubles. Serves depending on the brand and model from 20 to 50 years. Absolutely sealed. There are no metal cons: heat / sound / electrical conductivity. You will not cut the curvilinear roof with metal tile, but you can flex it. In contrast to the folded roof (the slope of the roof is 7–30 degrees, the optimum is 10–15) with bitumen tiles it is possible to cover slopes of any steepness, up to negative surfaces.

Ceramic tiles to the budget cover does not apply, from 1000 rubles. Lifetime is practically unlimited: in Europe there are houses with ceramic roofs built two years old and older. But, unlike all the listed roofs, pottery is heavy. Need a reinforced truss system.

Price for folding roof workThe territory of Russia is characterized by harsh climatic conditions in which cold and high humidity prevail. This explains the high demand for metal roofing of the country's inhabitants. It is roofing steel that can be called an ideal protection of a structure against the effects of various atmospheric phenomena. Fold roofing is considered to be one of the current technologies, due to which the joints of metal sheets are completely sealed. Fold roof deviceFold is a special type of joining of sheets of metal, which was the basis for the name of the roof. Fold connection is a special seam created by a self-snapping edge. Vertical folds are most popular, but horizontal joints are also encountered. Specialists in roofing work distinguish several types of folded roofs:

Types of metal for the manufacture of rolled faltsevoy roofThe quality and performance characteristics of the folded roof are determined by the material for the folded roof. Modern manufacturers offer several options:

Sheet metal with curved edges for folded connection is called a picture. In addition, roll materials are produced, they are most often ready for laying, it suffices to cut them into certain segments and fix them on the crate. Copper and titanium-zinc coatings require careful handling to prevent damage to expensive material. It is also not recommended to step on the cover, scratch it or throw it. Careful handling contributes to the extension of the service life of the folded roof. Main advantagesThe main advantage of the faltsevoy technology is the possibility of operation in the harsh winter conditions that prevail in Russia. In addition, sloping seam roof has the following advantages:

Installation of a cattle roof with a double foldNot everyone can install or repair a folded roof independently, most often this work is transferred to experienced roofers. In general, the laying of such a roof is carried out according to the following scheme:

Installation of a rolled faltsev roof not only simplifies the process, but also reduces the time for its implementation. From the rolls can be cut into strips corresponding to the length of the slope. At the same time horizontal joints are completely excluded, which minimizes the risk of leakage and increases the service life of the roofing material. A modern folding machine is used to create blanks for different types of folds. I will talk in stages about the principle of operation, types and popular models of machines, as well as explain how to make a folder with your own hands. Production technologyThe faltserokatny machine is irreplaceable both at arrangement of the faltsevy roof itself, and for production of auxiliary roofing accessories. These include elements of the gutter system, frontal and end overhangs of the roof, as well as using it to make ventilation boxes made of galvanized. Types of foldsThe folded joint is a twist between two adjacent sheets of metal, and in order to equip this twist, you need to bend the seam on the edge of the sheet, and this is exactly what the folding machine needs to bend in this fold. Folded connections exist 2 - this is a single and double fold, plus folds can be standing and recumbent.

As for recumbent connections, they are exactly the same as standing ones, only wrapped on their sides.

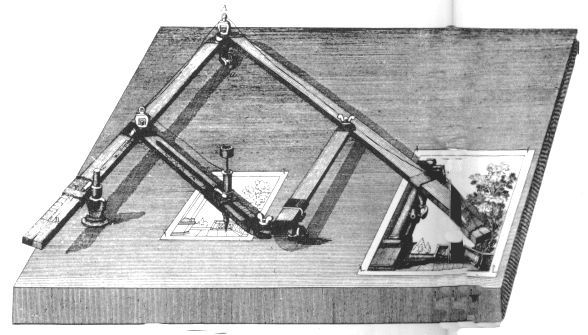

General information about the machinesThe main advantage of a faltsevy roof is that the covering turns out monolithic, without any fixing or connecting openings. But the roofing metal itself is quite thin and making blanks in production, and then transporting them to the object is inconvenient, and often unrealistic. A small folding machine radically changes the situation. With such equipment, you can make blanks directly at the facility, moreover, there are models that can be installed directly on the roof. There is one more important nuance: a folding machine is needed to bend the edges of the sheets, and a folding machine is used to make a double fold and pressurize the connection, bringing it to the final result.

Often the thickness of the metal for roofing fluctuates around 0.5-1 mm, with a maximum of 1.2 mm. But a good machine for a folded roof is calculated for work with metal from 0.3 to 1.5 mm. Such equipment is closer to the professional one, and it is possible to make not only roofing pictures on it, but also to bend the workpieces for various kinds of drainpipes or ventilation pipes, plus to make end gutters and ridges.

The principle of operation of the unit is simple: any faltserokatny machine has a number of crimp curly rollers, which actually bend the edges of the sheet. Crimp rollers are installed in pairs on the crimp rollers.

The number of such crimping shafts can be different, but, no matter how many, they are driven by a gearbox, and the gearbox itself rotates due to an electric motor. There is, of course, equipment with a manual drive, but the performance there is very low and such devices are rare. Most popular models

How to assemble the machine yourselfNot every master can afford a folding machine, so quite often people assemble such devices manually. A homemade folder certainly does not have such a wide range of functions, but it will cost only 2-3 thousand rubles.

Folding roof - a great option for roofs with a slight slope. The German masters invented the folded roofing (perhaps you guessed it by name). In translation, "fold" means only a gutter, and from such simple connections the installation of a folded roof also consists - snapped or squeezed, and that was that. But why then, with such simplicity, a folded roof occurs infrequently? The problem is that before the fold was made from sheets only by hand. The process was laborious, the joints were not very smooth and it was difficult to speak about the tightness of such a roof. And only with the advent of professional equipment, the folded roof opened itself anew: straight joints, any length and speed of installation did their job. Want to know more? The roof, which is made of individual metal sheets, called folding. In Russia, the folded roof appeared a little over 100 years ago, and quickly gained its popularity. And with the production of mechanical and electrical sealing tools (before the seam was connected only by hand) its installation became available to all. See for yourself: Of the benefits:

And still quite simple installation: We note immediately that all the flaws that are usually attributed to the folded roof come from the wrong installation.

And now look what else you can do to get rid of the noise:

The choice of design and materialTo be comfortable, we offer to start a little to understand the concepts. Pictures - These are rectangular metal elements with folds, which are mounted on the roof. The standard form - steel sheets in the form of a rectangle with carved corners. From the paintings and spread seam roof. Falts - this is a specific seam, which is obtained due to the bond between different metal webs. The advantage is that with such a connection the density is quite high, and neither sealants nor adhesive compositions are needed to ensure complete tightness. And, besides its main task, folds play the role of more ribs for the entire roof. Clammer- This is a special piece of fasteners, which are nailed directly to the base of the roof. A simple clamp has the same shape as the future billet of the fold, and the movable one provides the future thermal expansion of the metal (compression and stretching at different times of the year). As you can see, everything is simple and you don’t have to bother about anything. Material for making paintingsMake a faltsevy roof both from galvanized steel, and from different non-ferrous metals. Here are the materials from which most often make a folded roof: Option # 1 - steelThe most common option. The steel faltsevy roof can be galvanized, not galvanized or in addition covered with polymer. Of the benefits - corrosion resistance, low cost and durability (60 years of service). But over time, steel, unfortunately, noticeably tarnishes. And therefore for the device of a faltsevy roof steel pictures need to be taken only such which are covered with a color multilayered covering. And when buying one, make sure that there is a special protective film on them - only this way the material is not scratched during transportation. But in any case, even a high-quality polymer coating on the roof will not be durable: due to sunlight, acid rain and the most important enemy - a humid maritime climate. Option # 2 - copperThis is the most beautiful roof that just burns on a sunny day. Its main advantage is that no biological animals will take root on it, especially moss. But there are a lot of minuses - such a metal is a bit soft, it requires careful handling and is quite expensive. With time, copper is also covered with a patina - a layer of oxides, and becomes dark brown. And after that - green, and nothing needs to be restored. And precisely because of oxides, copper cannot be combined with other materials on the folded roof. Copper faltsevoy roof is also valuable for its flexibility - it is easy to make roofing architectural masterpieces by it, not to mention simple roofs: Option # 3 - ZincZinc rebate roofing is additionally covered with a protective layer - zinc carbonate. Over time, this roof gets a chic silver-gray color. Zinc roofing is about 50 years old, which is relatively short, and therefore in Europe such material is not used for making paintings. Option # 4 - AluminumSuch a roof is the most resistant to mechanical damage and corrosion, and can last more than 100 years! A pleasant silver shine will only please the eye. In addition, this material is lighter than steel and more resistant to corrosion. But aluminum is bad because it expands and shrinks much more when temperature drops. That is why the installation of such a roof has its own characteristics:  Option # 5 - zinc-titaniumIt is a strong, successful alloy of zinc and titanium: zinc is not susceptible to corrosion, and titanium has both strength and ductility. This sleep is also valuable for designers, because over time it is covered with a noble patina. The roof looks great! Option # 6 - aluzincAluzinc is an aluminum-zinc-coated steel painting that has valuable self-healing properties and perfectly protects scratches and cuts from corrosion. Option # 7 - an alloy of three metalsTitanium-zinc-copper alloy. There is not much copper here, only 0.005%, but this is enough to give the roofing material plasticity, thanks to which profiling is facilitated. Special coatingIf your home is located in a seaside area or in a zone with a poor environmental situation, or simply with a hot and humid climate, then purchase folded paintings covered with purals. Only this polymer is capable of protecting at a high level from sea air, rains with acid impurities and scorching ultraviolet radiation. Production technologyThe folded roof is also divided according to the production technology - cast and rolled. It has long been used in Russia was cast roof, and its reliability has already been tested. It is easy to assemble such a folded roof with your own hands and without special tools, there are no transverse joints, and the surface is complete and durable. But rolled seam roof - this is a new technology with its own advantages and disadvantages. These are metal strips for the entire length of the slope, and immediately with the prepared edges on a special machine. The fold is formed double. And according to the width of the paintings and the presence of stiffeners, the folded roof is divided into the following types:

And still fold panels can also be privates and starting, trapezoid and parallel:  Market offersIf we talk about brands, in Russia, as well as abroad, the most popular Finnish folded roof from the company Ruukki, with self-snapping folds. More pleasant prices - for the materials of the domestic plant "Insi". It has been on the market for more than 16 years, and is quite pleased with the quality of its products. In the production there are both ordinary glossy and matte paintings, as well as unique ones, for creating a special design of the roof. Installation technology faltsevoy roofFor the installation of such a roof, neither special supports, nor expensive lifting equipment, nor additional consumables are needed. Stage I. Preparing the FoundationIt is possible to arrange faltsevy roofs both on an obreshetka, and on the continuous basis. Both bars and metal hat profiles are suitable. It is only important to adhere to the step between the rafters of no more than 2.5 meters - otherwise even the strongest steel sheets risk bending and the seams will immediately disperse:  And here is how to bend the lining sheet by yourself:  Stage II. We work with picturesYou can bring both finished paintings and rolled steel to the workplace, which you will cut off on the spot. As soon as the steel paintings are ready, they are raised to the roof. Lay out along the eaves directly on the batten and begin installation from the middle. Stage III. We harvest additional itemsFor roofing the edges of the roof, valleys, ridges, and such elements as the chimney, the roof joint and the dormer window, it is necessary to pre-fabricate ready-made paintings from rolled steel - but already in figure form. Here is a detailed master class on how to make yourself a drip for a folded roof:     Stage IV. Bend foldsSo, we have come to the most important technological question: how to make folds? Types of compoundsThe folds in such paintings are single and double, standing and recumbent. If to simplify, then all horizontal folds are called lying and vertical ones standing as standing:  A single standing seam is the easiest to install:  Double rebate is a double bend edge. It must be done in the most problematic areas of the roof, where snow and water usually accumulate - valley, troughs and other complex compounds. It is the strongest and most airtight, which is why the most popular abroad. A double standing rebate is recommended for roofs with a slope angle of less than 25 °. True, in Russia a double rebate is still considered an unreasonably expensive technology. Although in fact the price is exceeded quite a bit, but the reliability of such a connection turns out to be much greater. Here is how you can make it in the process of mounting the roof:  But, if you want the seams between the paintings to not be views, and the whole roof looks even - then make recumbent folds. Yes, and horizontally, the pictures are connected only by lying folds - so that the coverage is maximum. If the captured steel strip does not reach the depth, such pictures will eventually diverge. The third type is an angular standing seam, which is also called L-shaped. It is recommended for roofs with a slope of more than 25 °. In performing it is easier than the usual fold - you just need to correctly bend the upper edge of the seam. Stiffener heightNow let's talk about the height of the fold, which also serves as a stiffener for such a roof. The fact is that this compound is absolutely waterproof, if only it is not subjected to stagnant water. But where on the roof can it come from? Very simple - from the thickness of snow. That is why the fold height is important, and in especially snowy regions it is made considerable. Additional sealingAdditionally, in order to prevent water from entering the seam, special sealing gaskets are installed in the seam even during the installation process. A special material is used that calmly transfers the effects of high temperatures (up to 90 ° C) and compression, as rolling mechanisms will still be used for folds. Another important point: all fasteners that you will use should only be anti-corrosion. Otherwise, after a couple of years, a new beautiful roof will be covered with rusty streaks. Fold bend technologyIt is possible to fasten the folds to each other with a hammer and wooden bars, special hand tools or with the help of electromechanical machines. The easiest option - frame:  Before you bend the recumbent fold, the picture must be attached to the flooring with a separate narrow strip in order to stabilize its position. The bend is made from the front and back, and to the left and right are the vertical elements of the subflot. Klyammer applicationThe most common method of fasteners - klyammery. They are bent down by 25 mm, and the paintings are nailed on the right side. Klyammer - a metal strip of galvanized steel, 80-120 cm long and 0.5-0.7 mm thick. You can cut the clamp from a usual galvanized sheet with a simple hand tool. Next, place the clams on the edge of the paintings every 60 cm and fasten with screws (4.8x28). So, first put the picture on the crate, then fasten it with a clamp and only then cover it with another picture. The cleats should be nailed along the line of joining two pictures: one sheet is placed on the cleats above, and the second one is pushed from the bottom, and three layers of metal are wrapped in one direction, after which we close the folds to the end. We press, and we get a strong and reliable connection with the clamp, which is hidden inside and holds both sheets on the roof. Such fastening is a 100% guarantee for many years from leaks and cold air. And now let's see what makes a professional work different from an amateur one. So, for an ordinary home wizard with quite dexterous hands, a single mallet, scissors, and a crook hook are enough to install gutters. But an experienced person, an expert in his business, is armed with at least a dozen expensive special scissors, not to mention frames, tongs and other tools. Moreover, the total cost of such a kit may be more expensive than the folding machine itself. To close the folds today is often used semi-automatic tool, the use of which gives a lot of significant advantages:

Recently, paintings have also been made, the folds of which easily snap into place when pressed - and no tools! |

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners