Site sections

Editor's Choice:

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

- Surface grit - tooling work

- Maximum load on the balcony slab: how much can a balcony withstand in a panel house?

- Projects: symbols on drawings for water supply and sewage

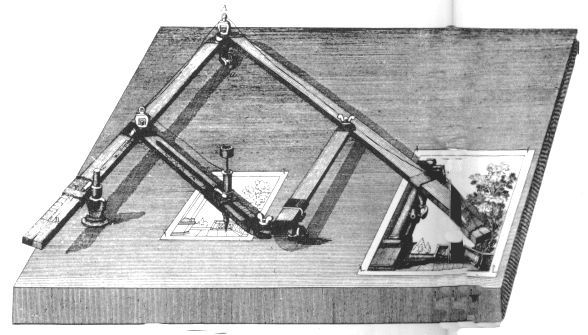

- Marking and marking details How to mark the details with curved contours

- Tools for slotting Tools for slotting

- Tools for chiseling Slotting tools

Advertising

| What parts is a chisel. Dimensions and weight |

|

Chisel for punch and for metal can be purchased at any specialty store. The times when this tool had to be “taken out” from work were long gone. And along with them, the vast experience of sharpening and hardening metal at home is melting before our eyes. We will try to restore the gap of this knowledge now. Punch chisel - variety of shapesThe chisel is not only the collective name of the car Lada Samara, but also the shock-cutting tool used to process stone or metal. On the one hand, there is a cutting edge, and on the other, a striker part, referred to as a butt pad. The butt plate is designed for striking, the edge - for cutting or splitting material. Punch chisel is very different from the fellow in both shape and content. The shank has a special shape for landing in the cartridge punch. For household tools weighing no more than 5 kg, use a form shank SDS +. Medium punchers, 5-12 kg, clamp the chisel with a shank SDS-max. More powerful devices, weighing over 12 kg, intended for the dismantling of asphalt and serious concrete structures, use a hexagonal fastening HEX (19, 28 and 30 mm). Forms for concrete jacks are very different and for all occasions. Consider them in more detail:

Using a chisel on the concrete for a perforator, do not forget to periodically lubricate the tool shank with a special lubricant. This will extend its service life. Many do not attach much importance to this, but in vain. He is experiencing no less stress than the chopping edge, having almost the same hardening. Chipping metal chisel - like clockworkChisel on metal (metalwork) is a rod of rectangular cross section. The cutting edge consists of four planes, two main and two auxiliary. The impact part usually has the shape of a truncated cone, this helps to ensure the correct direction of impact. The most commonly used tool length 75-200 mm, with an edge of 20-25 mm. To cut the grooves in the metal used kreutsmeysel (a type of chisel), it has a slightly smaller length, 150-175 mm, and an edge of 5-10 mm, but except for the workshop of my grandfather it is nowhere to be found. Serious chisel work on steel and can not be found. Draft work performed by grinders and gas cutters, and finishing work - milling machines. Cutting metal with a chisel is already a classic, but it should not be forgotten; let us remember how the processing of blanks in yews takes place. The future detail is chopped off either by level or above the level of yew sponges. When chopping at the level, the cut is smoother, and the workpiece is not subjected to deformation. The metal is tightly clamped in yews so that the top edge of the cut edge protrudes by 3-4 mm, this is the most optimal value. If you make it more, then the chips will be removed more difficult, if less, then the process will take longer. The protruding part of the cut down, then rearrange the item, releasing on top of the jaws of the yew again 3-4 mm, and again remove the chips. This operation is repeated until the desired size is reached. If the processing is performed above the level of the jaws, the workpiece is clamped so that the processing line is parallel to the jaws and 3-4 mm above them. During operation, the cutting edge of the tool should be placed at an angle of 45 degrees to the metal being machined, and the impact part is raised by 25-40 degrees upwards. This arrangement helps to achieve a more even line of the log house. In simple operations with a steel strip or reinforcement, for example, cutting, a chisel is placed perpendicular to the material, then half the length of the strip is cut through with one or several blows. Similarly, they do it on the other side of the workpiece, and if it is round, the rod is turned, processing the rod around the circumference. Work with metal only on the anvil or on a thick steel sheet. How to temper a chisel - we will lay everything on the shelvesThe chisel is made of carbon steel, so it is necessary to temper this tool at a temperature of 750-800 degrees (the color of the eel cherry). The chisel for concrete is made from alloyed steels, its quenching temperature is higher. If you have a homemade tool, then it should be cast in a certain temperature range, depending on the steel grade. For example:

Warming up of the tool is made evenly, in order to avoid a sharp temperature difference between the cutting edge and the chisel core. When the required temperature is reached, the product must be kept in the oven for some time. It is better to warm the instrument evenly for 1 hour and hold it in the oven for 30 minutes, than to heat it to the maximum possible temperature in 10 minutes and cool it immediately. You can cool the chisel in water or oil. Do not skimp on the amount of coolant. Half of the cut plastic bottle does not suit us, but 2-3 liters of oil in a galvanized bucket is what we need. For the formation of ferite-cementite mixture (the most durable mixture of iron and carbon, with high resistance to shear on the slip plane when exposed to external loads), the metal must be slowly cooled to a temperature of 650 degrees, and from 650 to 400 degrees you need quick cooling. When a liquid medium comes into contact with a hot metal, the liquid begins to float and envelops the tool, as a result, the metal does not directly contact the coolant. A film of steam is formed around it, called the steam jacket. Such an external environment slowly cools the steel. When the temperature of the material decreases, the oil or water stops evaporating, the shirt disappears, and we get faster cooling. Thus, oil and water equally affect the metal.

It is necessary to lower the tool perpendicular to the surface of the oil, in any case not sideways, not at an angle and not throw it into the bucket. Immerse the tool with the cutting part down, smoothly moving it up and down and right and left. This will prevent a sharp temperature difference between the hardenable part and the non-hardenable part, and also allow you to quickly get rid of the steam jacket. In addition to the edge, it is necessary to harden and shank. He, too, is experiencing shock loading and without quenching after a short work will begin to overgrown with "curls." We temper it like a cutting edge. As a result, we obtain a rod with hardened edges and not a hot, elastic middle - a balanced tool. Sharpening chisel, cutting edge and shankThe blade has the shape of a wedge, but the wedge is different, and the angle of sharpening the chisel depends on its application. It seems that the sharper the angle, the less it is necessary to apply force to strike. But the sharper the angle, the faster it gets dull when working with hard materials. Therefore, many years of experience with chisel smoothly brings us to a compromise. For cutting fragile materials (iron, bronze, hard steel) the chisel blade sharpens at an angle of 70 degrees. For steel of average hardness apply a 60-degree angle. Soft materials (copper, brass) are cut with a sharpening angle of 45 degrees. Aluminum and zinc can be cut with a blade angle of 35 degrees. Sharpening a chisel, of course, is better when applying coolant to the sharpener, but at home it is almost impossible. Because of this, when dry grinding, you must be careful not to overheat the tool above 110 degrees, otherwise its hardness will decrease. After sharpening, the cutting edges should have the same angle of inclination and width, therefore in the process of work it is better to work each side slightly, often turning the chisel over. At the end of the sharpening process, we remove the chamfer from the shank, giving it the shape of a truncated cone. Do not forget about the safety rules - use glasses or a protective screen. Sandpaper dust is extremely harmful. The chisel on concrete for the perforator almost does not need sharpening. All manufacturers use Long Life technology. The blade of the tool itself is sharpened when working. Qualitatively tempered chisel will be less deformed and erased in the process. And the correct sharpening will help to chop any steel and crumble any material. Table of contents of the book Next page \u003e\u003e§ 51. TOOL FOR CUTTING. Cold chisel. Kreuzmeisel. Trenchman.Cold chisel(Fig. 84, a). It is made of carbon steel U7A or U8A and consists of three parts: working, middle and head. The working part 2 of the chisel, as well as any cutting tool in general, has a wedge shape, which is ground at a certain angle, which facilitates the process of metal cutting and the formation of chips. The width of the cutting edge of the chisel is usually 20-25 mm. The angle of sharpening 1 chisel is selected depending on the hardness of the treated metal. The harder the metal, the sharpening angle of the chisel is taken more, and vice versa. Usually, the angle of sharpening is made when cutting iron, hard steel and hard bronze 70 °, medium and mild steel 60 °, brass, copper and zinc 45 °, for very soft metals: aluminum, electron and others - 35-40 °. The middle part 3 of the chisel has a shape that is comfortable to hold during felling. Most often, the chisel has an elliptical or multifaceted section. The edges of the chisel must be sawed and trimmed. The head 4 of the chisel is always made on a cone and somewhat convex (spherical). This form makes it possible to reduce the area on which the blow is struck, and thereby ensures the centering of the blows with a hammer. The conical head, moreover, less rivets during operation, and a smaller fungus is formed on it. Fig. 84 Locksmith chisels: a - chisel, b - kretsmeysel, v - groove: 1 - sharpening angle, 2 - working part, 3 - middle part, 4 - head Chisels are used in lengths of 100, 125, 150, 175 and 200 mm. The working part of the chisel hardened to a length of 25-30 mm and released to hardness HRC = 52-57. The impact part (head) of the chisel is hardened to a length of 15-25 mm and released to a hardness of HRC 32-40. When testing chisels for strength and durability, they need to chop off a steel strip of Art. 2 4 mm thick, 50 mm wide. After the test, an external inspection on the working part of the chisel should not reveal dents, spalls or visible signs of blunting. The degree of hardening of the chisel can be determined with the help of a personal file, which, when machining the hardened end of the chisel, almost should not remove the metal or leave only a minor mark. Not enough hard-hardened tip will be amenable to file processing. If, even with proper hardening, the chisel is unstable, it means that it is made from an unsuitable grade of steel or is allowed to burn through during hardening. Kreuzmeisel(Fig. 84, b). It is intended for cutting out narrow grooves and keyways, chopping rivets, etc. However, it is often used before chisels are used to cut large planes. For example, if you need to chop off the entire upper face of the cast-iron wide slab, then the processing will be easier and more accurate if you cut the grooves with a pre-cutter bar and then remove the remaining part with a chisel. Krejtsmesel is a chisel with a narrower cutting part. The angles of sharpening and all other elements are exactly the same as that of a regular chisel. When testing the crosshead, they need to cut a keyway with a depth of at least 3 mm, a width equal to the width of the cutting edge for a length of 40-50 mm in a plate or rod of the appropriate diameter of steel Art. 6. During external examination after testing on the working part of the crutzmeisel, no dents, crumbled places or blunting marks should be found. Trenchman (Fig. 84, c). They are used for cutting out profiled grooves: semicircular, dihedral, etc. It differs from the crossbutton only in the shape of the cutting edge. Traditional locksmith operations gradually change in the nature of production, which is affected by the development of the tool. The capabilities of machine tools, pneumatic and electric machines are spliced with hand-held devices, ultimately allowing the master to more effectively cope with the tasks of cutting and cutting. Nevertheless, the demand for a simple classical instrument is also maintained. Using a chisel, you can get a high-precision groove, groove, or even a technical hole with maximum accuracy, limited only by the user's skill. Design and principle of operationThe typical design of this tool is based on a metal rod. Its one end is functional and implements chopping actions. The other end is provided with a nozzle in the form of a handle, which, in turn, has a dual purpose. Firstly, the metalworking chisel turns out to be a shock effect through the holder. Secondly, the master positions the cutter while holding the tool by the handle. It is important to note the variety of chisel configuration solutions. Both the working cutting part and the holder can be made in different versions. Even the handle has different cross sections, defining where a metal chisel can be used. GOST 7211 86 identifies several types of holders, among which are models with I-shaped, hexagonal, oval and semi-oval sections. As for the cutting head, it can also be flat, round, square, etc. Tool types

The fundamental differences in the chisel models are determined by the functional capabilities, which also depend on the design and shape of the tool. For example, for home use experts recommend a version with a protector. It is a chisel, the handle of which is provided with a protective device for hands. In practice, this means a more confident grip and increased protection against accidental impact. Especially for caulking use models with an extended workspace. If you need to choose a chisel for fitting gaps, joints or cleaning flat surfaces, then it is possible to prefer this option. From the spatula, he, of course, will be different strength and rigidity. There is also a category intended for power influences. This is a weighted tool that can be used in the process of point and accurate destruction of concrete and brick structures. Of course, there are also hybrid versions of chisels designed for universal use. Moreover, some models provide the ability to change the working tip, which, however, is not the best way affects the reliability of the tool. User's manual

Before you start working, you need to check the status of the tool. Special attention is paid to the handle, since it is often not made of metal and may be physically damaged. Both the metal functional part and the holder must be in the cleaned state. The workflow consists of cyclically repetitive chopping operations. First you need to fix the chisel is set at the cut and held with his left hand. Further, using a sledge hammer or hammer, it is necessary to strike the end of the holder with the right hand from the shoulder. Impact energy will depend on the applied force and, accordingly, will determine the nature of the result obtained. Depending on the characteristics of the chisel itself, it is possible in this way to make a rough cleaning of the log, and to make a neatly shaped cut on the surface of the wood massif. Manufacturer ReviewsThe metalwork manual tool is rather widely presented by domestic producers. Good reviews are received by the brands “Zubr”, “Enkor” and “Russia”. Another thing is that most models of these brands are simple chisels, often devoid of functional handles. In this way, there is a plus. Owners of this type of monolithic rod instruments note their high reliability and durability. At the same time, the cost of this product rarely exceeds 500 rubles. Foreign chisel, the price of which can be about 2-3 thousand rubles, often comes in sets. For example, high-quality kits are supplied by manufacturers Jonnesway and Stanley, using new technological materials in the manufacture of tools.

What to consider when choosing a chisel?Appointment is the main selection criterion. The shape of the section, the presence of the handle and the tread - these and other design features will further determine both the ergonomics of the model and its effectiveness in the performance of various working actions. At the same time, the product life should be taken into account. According to GOST, a chisel chisel along the blunt radius in the working part should have no more than 0.4 mm. In order not to miscalculate in the choice of this parameter, it is desirable to focus on the version of high-strength tool steels. As for the kits, they should be purchased with the expectation of performing various plumbing and carpentry tasks. For highly specialized use, it makes sense to purposefully acquire a model with suitable properties. Again, this choice takes into account the cross section, the width of the working base, the ability to protect hands and other characteristics. Conclusion

Tool manufacturers are actively expanding the range of electric and pneumatic tools, which replaces the functions of conventional manual models. So, a chisel chisel already competes with some modifications of planers and planers. But here it is important to understand that by far not all operational capabilities make the transition to mechanics justified. Of course, the same electrical devices will benefit in speed and performance. But if you want to perform a decorative trim or a point liner wooden base, it is better not to find the chisel option. The rest as processing by this tool will depend on the skills of the contractor and the complexity of the operation performed. One of the most common tools for processing metal and wood is a chisel. This is a shock-cutting tool with which you can perform various tasks. In this article we will talk about what this tool is, how and what it is intended for, what types of chisels exist, and how to buy a chisel correctly and better, depending on the purpose for which you need it. For what and how to work with a chisel?The chisel device is very simple - it is a small, thick, metal finger that has two ends. One of the ends is the impact part, and this end has a flat cap. On the other hand, the chisel has a sharp shape. This form can have a different type of edge, depending on what tasks it is sharpened. The principle of operation of the chisel is elementary - so, when the impact force is communicated from the side of the impact part (which is applied by a hammer, sledge hammer, perforator, or other device), the cutting edge of the chisel affects the material with which it comes into contact. So, she can cut or split it, depending on how much power to apply, and what needs to be done. Note that in some cases, a special head can be put on - a “fungus” on the instrument. In this case, the chisel becomes safer from the point of view of work, since striking a cap, the risk of a miss is significantly reduced, respectively, and injuries are reduced. Manufacturing materials chiselsA very important criterion for a chisel is the material from which it is made. First of all, it is worth noting that both ends of the tool are subjected to thermal improvement, since these parts account for the main load. In general, for the manufacture of chisels use the following types of steel: - atcarbon steel tool steel (for cutting metal); - tostructural steel with carbide plates (for cutting stone). In addition to the function of cutting metal or stone, the chisel can be used for completely different purposes. For example, as an improvised wrench, with which you can loosen or tighten the nut with the "pinched" edge. Types and types of chiselsNow, consider in more detail the types of chisels, which are most often used in practice. It is clear that, depending on the type of chisel, its functionality and purpose will be different. Well, what types of chisels are known to us? Cold chisel. Perhaps the most common type of this tool, which is used for cutting non-hardened metal. This type of tool can be found in almost any master or just a man who knows how to handle tools. With this chisel, you can perform various tasks, ranging from those provided by the device tool, and ending with improvisation of its use.

Kreuzmeisel. One type of chisel, which has some structural differences. So, if a regular chisel has a regular, pointed edge, then in the case of a cromeyselle, this edge also has a tapered appearance. This is necessary for cutting grooves, as well as small grooves on the metal surface.

Trenchman. This type of chisel is one of the varieties of kreysmeysel, which differs only in the presence of curly cutting edge. Using this edge, you can make curly cuts on the surface of a metal or stone (depending on the material of the tool, as we said above).

Pick-chisel. Actually, it is almost a common chisel, but it has one constructive difference. It is intended to equip electrical tools. This includes a chisel for a perforator and a chisel for a pneumatic breaker, for various jackhammers or chipping hammers, and so on. The shape of the cutting edge of the tool is no different from a conventional chisel.

Blacksmith chisel. Another type of chisel, which is the presence of a wooden handle, like a hammer or pick. This feature allows the worker (blacksmith) to move away from the surface of the hot metal, to a safe distance, and continue to perform work. But, it is not excluded the use of such a chisel and for cold cutting. In addition, such chisels can have both a classic edge shape and a tapered edge, depending on the tasks that the master needs to solve.

So, to buy a chisel, first of all, you need to set a task - what is it for? If you are going to work with metal, pay attention to the chisels of carbon, tool steel. If it will be work with a stone - use chisels made of structural steel. Next, be guided by what you will do and when to use the chisel. Use it manually - stop at the chisel. We decided to use the tool in combination with some electric device - use a chisel for a punch, for example. And, of course, always pay attention to the chisel manufacturer. As a rule, tools from an unknown manufacturer may turn out to be of poor quality - the ends of the chisel may not be thermally processed, so the metal will be soft and it will quickly become unusable. A good and high-quality chisel will last a very long time, and it is unlikely to ever need to be replaced. SITOMO Chisel (SIT) is a durable and reliable tool that is made of 45 tool steel with an oxidized coating that protects against corrosion and corrosive media. The working cutting edges are hardened and have increased strength. This SIT tool is manufactured in accordance with the TU and GOST 7211 86 and is offered in two types: forged chisel and flat chisel. Sheet Metal CuttingSheet metal cutting is very convenient to produce with a chisel. To carry out this operation, the first thing a mechanic takes a pencil or marker and marks out the cutting line. Next, the cutting edge of the tool is combined with the intended line, after which the chisel is struck with a hammer or sledgehammer. Dismantling broken nutsExperienced locksmiths for removing old plucked nuts mostly prefer to use a chisel GOST 7211 86. To solve this problem, a special cut is made on the nut, into which the sharpened end of the chisel is inserted. Further a blow is struck on the tail part of the tool, and the plucked nut is removed. Everything, at first glance, is quite simple, but you need to understand that plumbing skills are still required. Cutting metal in high explosive conditionsWhen working in fire and explosive areas and objects, one should remember that a fire can occur even from an accidental friction spark. For example, when repairing tanks and tanks, it is not uncommon for a specialist to adjust a patch in size right on the spot. For these purposes, the Chisel flat 160x16 oks is very suitable. SIT *, but it must be remembered that the technical regulations when working in hazardous environments require the use of only copper-plated tools. No problem! It is possible to buy a copper-clad chisel of 100, 125. 200, 250 or 300 mm directly from our warehouse in Moscow, moreover, at a very favorable price. We also dare to assure you that the SIT coke intrinsically safe fitting tools completely eliminate the risk of fire or explosion when working with it. How to buy?In our company you will buy, for example, a chisel 200 mm with payment by bank transfer. We assure that our prices will please you. You can pick up your order either by self-pickup from our warehouse in Moscow, or by ordering transportation services at any transport company whose delivery to the terminal within Moscow we carry out at our own expense. |

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners