Site sections

Editor's Choice:

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

- Surface grit - tooling work

- Maximum load on the balcony slab: how much can a balcony withstand in a panel house?

- Projects: symbols on drawings for water supply and sewage

- Marking and marking details How to mark the details with curved contours

- Tools for slotting Tools for slotting

- Tools for chiseling Slotting tools

Advertising

| Milling machine pantograph. Homemade pantograph - how to make a pantograph with your own hands. What is copy milling machine |

|

The basis for the manufacture of the machine with their own hands will be manual. Fix it on a wooden support made of thick plywood (not less than 12 mm thick). The support also makes several holes for fasteners and the bit holder. Additionally, you should build a frame and make a few bars, which are installed on the edges of the support, they will hold the machine during operation.

Manufacturing milling machine As a guide, we use a metal pipe of average diameter. We install a carriage with a router in the pipe. At the carriage fasten the bar, which plays the role of the copy probe, after which you need to fix the horizontal bar, which is attached to the main template. A machine made according to this principle can be used to process and create copies of simple household products, such as door handles, locks, furniture legs. A milling machine with a motor is inserted into the carriage and is connected to the power supply. The template is fixed on the support, the copying probe moves along it. The router works on the network, the carriage moves manually, so that the working head repeats the movement of the probe. To create more complex models, you need to connect additional working heads and install a drive with a belt drive. Now there is the possibility of connecting a self-made installation to the software, but this will require a CNC and additional equipment and tools. Such a homemade machine will cope with their everyday functions quite well. 4The practice of using self-made copy milling machines of various types shows that the final part made on such equipment has certain discrepancies to the drawings and forms and some manufacturing defects in the form of chips and curvatures. These flaws are due to the constant vibrations of the machine and the movements of the working head. Get rid of them in the home is very difficult.

DIY Copy Milling Machine To avoid such shortcomings in the work of home-made equipment, we recommend to make highly specialized machines, and not equipment of a universal type. That is, before starting work on the manufacture of the machine with your own hands, it is necessary to determine under what specific details it is planned to use it. So you can optimally choose the weight and size of the manual milling machine. It is important to remember that the larger the size of parts for processing, the more powerful and heavier the working installation should be. For larger parts, additional holders and a more massive support are needed, this will allow maximum damping of vibrations that will occur during operation. In addition, it is better to use an electric drive instead of a manual one and ensure that the guides have an adequate margin of safety. Remember that the type of working surface depends on the smoothness of movement of the cutting equipment in different planes, and hence the final result. Nowadays, there is often a need to create a copy of some object. For these purposes, modern enterprises use special copying machines, the shape of which most closely matches the desired sample. Such milling copiers make it possible to manufacture parts of various complexity and shape. In this case, the equipment must, in a short time, process and manufacture the required element. Factory or homemade machine?The modern market offers to purchase milling and copying machines of various levels of complexity and design. But it is not always possible to make such a purchase, and the cost of such equipment for wood is quite tangible. That is why folk craftsmen often have a question about a self-made milling and copying machine, the production of which is less expensive compared to self-assembly. Now, in the case of the availability of relevant drawings, materials and skills, such equipment can also be made by hand. It is clear that such a variety of home-made equipment cannot compete with factory-made equipment in terms of its parameters and usability. But with a reliable version with a machine-made with their own hands, you can make enough high-quality copies of certain objects made of wood.

That is why you can make a copying machine on wood with your own hands only “from scratch”, using the systems of the electric motor and a special cartridge in which the mill will be engaged in processing the workpiece. What is a copy milling machine?

The constructions of self-made equipment of such purpose exist in our time quite a lot depending on the drawing used and the tasks that will be performed on this technique. A typical tree copier consists of the following basic elements:

The milling head must be equipped with a transmission mechanism with an electric motor, which can provide several speeds of a homemade milling and copying machine for wood. A large number of national craftsmen, who made such a machine by their own hands according to the drawings, note that as a result of copying the finished part has a sufficient number of flaws. They appear during the change of direction of the cutter, shake and vibrations of the whole structure. In addition, inconsistencies also occur due to the curvature of the workpiece, which occurs when the internal stress increases as a result of the production of a wooden piece.

Features self-create copier

Thus, the copy milling machines in the manufacture of their own hands must be optimized for the processing of specific parts that will be produced on it. Otherwise, there may be various side effects that are often very difficult to correct. Quite an important factor that must be taken into account when hand-made production of the machine-copier is its size and total weight. The larger products will be processed on it, the more massive the whole structure should be. This will allow the equipment to absorb vibrations that occur during the operation of the cutter. The guide axes must be made so that they have a significant margin of safety, without bending under increased loads. The optimal properties of the copy-milling machine for wood in the manufacture of his own hands can be chosen empirically, since it depends on the design of the equipment and the purposes for which it will be used. What you need to consider when developing a machine?

Also the power of the electric motor necessary for high-quality work, which provides the cutter rotation, depends on the parts produced and copied on the machine. But in most cases, 150-220 W of a DC motor can be sufficient for processing wooden parts. To ensure maximum accuracy of copying parts, the device holding the router and copying probe should be as securely fastened as possible. At the same time, their planes, along with the height above the working surface, must coincide in full.

Thus, it is not very difficult to make a copying machine for the manufacture of various parts from wood, so many can handle this work. But we must remember that in the case of the manufacture of such equipment with their own hands, it is suitable only for the production of products of a particular type. Otherwise, only modern factory-made universal equipment will do.

Both in production and at home, there is often a need to manufacture a part, the shapes and dimensions of which are completely identical to the original sample. At the enterprises, this task is solved with the help of such a device as a copy-milling machine, which allows you to make copies of the original part in large batches, has a high speed, as well as the quality of processing performed. What is the milling process?Copy milling machines and any other equipment of the milling group can be found at almost any industrial enterprise. This is explained by the fact that the milling operation is one of the most common methods used to perform machining. This technology allows you to perform a wide range of roughing, semi-finishing and finishing operations with simple and shaped blanks from ferrous and non-ferrous metals, to work on wood and plastic. Modern milling equipment with high precision and performance handles even the most complex shape parts. There are two main types of milling: the counter (feed and rotation of the tool in different directions) and passing (the tool rotates in the same direction as the feed). The cutting part of tools that perform milling is made of various materials, which makes it possible not only to work successfully on wood, but also to process (polish including) even the hardest metals and alloys, artificial and natural stone. Milling equipment is divided into two types: general purpose and specialized, to which the copy milling machine belongs. Features of milling equipmentCopy machine belonging to the milling group, designed for copy-milling works with flat and three-dimensional parts. In addition, on such a device, it is possible to engrave shaped profiles, put inscriptions and patterns on products (even of high complexity), carry out light milling operations on wood and other materials.

Using tools with a cutting part of various materials, on the copy-milling machines process parts made of cast iron, different grades of steel and non-ferrous metals. On such devices for the production of parts in small and large batches successfully produce blades of turbojet engines and steam turbines, propellers for ships, punches of cutting and forging type, impellers for hydraulic turbines, molds for pressing and casting, molds, etc. On the copy-milling machine, technological operations are performed, which are practically inaccessible to universal equipment. The principle of operation of such a machine is based on the copying method for which a special template is used. The use of the template eliminates the human factor in the processing of even the most complex parts, so that all finished products have the same shape and geometric dimensions. Conveniently, one template can be used to precisely manufacture a large batch of parts that will be completely identical to each other. In order to copy the shape and size of the template as accurate as possible, a copier is installed on the copy milling machine (pantograph for the router). The purpose of such a device is the exact transfer of all movements of the copy head to the cutting tool. How does a copy milling machineCopy milling machines, as mentioned above, are used for planar (processing profiles) and volumetric (processing reliefs) milling. As a working tool, cutters are used on them, which, processing the contour or volume surface of the part, repeat the movements of the copier. The connection of the working body and the tracking system at hand-held machines is ensured by mechanical, pneumatic or hydraulic elements necessary for the formation of the force transmitted from the copier to the working body of the copy-milling machine. A template on such machines is a flat contour or spatial model, a reference part or contour drawings, and an element that reads the shape and dimensions of the template is a copying finger or roller, a special probe, a photocell. For the manufacture of the template, you can use aluminum sheet or a sheet of another metal, plastic or wood. The template and the workpiece are located on the rotating desktop of the machine.

The working body of the copy-milling equipment is set in motion thanks to such constructive elements as a screw, a spool valve, a solenoid, a differential or an electromagnetic clutch. Relays installed in amplifying devices of copy-milling machines, are electromagnetic, hydraulic or electro-optical. The quality of the workpiece (surface roughness, accuracy of shape and size) depends on such a parameter as the speed of movement of the tracking device. You can achieve the following characteristics of the finished product: roughness - №6, profile accuracy - 0.02 mm. The main elements of the executive circuit of such equipment are an electric motor and a hydraulic cylinder.

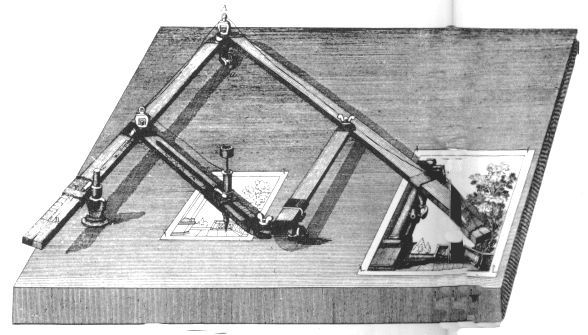

The pantograph installed on the copy-milling equipment provides copying at a given scale. The design of the pantograph consists of a guide pin, its axis, a tool spindle and a separate axis of rotation. The spindle and the guide pin are located on the same rail, the ratio of the arms depends on the ratio of the arms. Moving along the contour of the template, the finger drives the rail, which rotates freely on the axis. Accordingly, on the other side of the rack, the spindle of the machine makes identical movements, processing the workpiece. On the copy-milling machines, which are made by hand, such a device is also not superfluous, its presence significantly increases the functionality of the equipment. Kinds of machines of copy-milling groupEquipment of the copy-milling machine may include drives of various types. Based on this parameter, the following is distinguished:

The self-made copying machine can refer to any of these types (including copy-grinding machines). It is only necessary to find drawings on the Internet and pick up components.

According to the degree of automation and method of fixing the workpiece, the following categories of copy-milling machines are distinguished:

How a copy milling machine worksAs noted above, on a copy milling machine, the workpiece is processed using a master device - a copier. All movements of the copier along the contour or surface of the template are transmitted through a special (copier) device to the working head of the machine in which the milling cutter is fixed. Thus, the cutting tool exactly repeats all the movements made by the copier used to equip the router.

The movements of the elements of the copy-milling machine during machining are divided into main parts (rotation and movement of the spindle when the tool is inserted into the workpiece material, moving along the contour of the working table and slide) and auxiliary (movement of the spindle head, slide and table in accelerated mode, as well as adjusting movements that make tracer table, copy finger, stops and clamp, fixing the spindle head). In copying and milling machines working on aluminum, two tracking schemes can be implemented: a simple action and an action with feedback. When implementing a direct-action scheme, the machine body makes movements due to the fact that it is rigidly connected with a cam. The reverse action scheme does not provide for such a link and transfers from the copier to the working body are transmitted not directly, but through the tracking system. As mentioned above, on copying and milling machines perform contour and volumetric milling. In contour milling, the movements of the copier occur in a plane parallel or perpendicular to the axis of the tool. In the first case, the movement of the working table of the equipment can only be longitudinal, and the mill and the copy finger move vertically. In the second case, the table moves both in the longitudinal and in the transverse direction. In volumetric milling, the part is processed in stages - thanks to several movements of the table and the tool, performed in parallel planes. The scheme of direct action can be implemented through a pantograph, which allows you to reduce the size of the finished products in relation to the size of the pattern used (to scale). Most often, such an additional device, which is easy to make, is installed on the machines used for engraving and light milling operations.

Another variation of the self-made machine How to make a copy milling machine with your own handsMany household craftsmen would like to purchase a copy milling machine to equip their workshop, but the cost of such equipment is quite high. Meanwhile, with the desire, spending not so much time, effort and financial resources, you can make such equipment with your own hands. Naturally, improvised copy-milling equipment cannot be compared with a professional one in terms of its power, reliability and functionality, but you can also make high-quality copies on such machines, work on wood on them and process workpieces from other materials. Many try to fit a copying device to an existing one, but this is inexpedient, since in this case it is necessary to redo almost the entire machine. As practice shows, it is better to assemble your home-made copy milling machine from scratch, selecting the appropriate components for this. Below the photo shows an example of a homemade machine with the addition of a video. The creator of the machine is telling the story in English, but in principle everything is completely clear without translation.

The simplest way to make a copy-milling device with your own hands is according to a typical scheme, which includes a supporting structure - a frame, a work table and a milling head. The drive to ensure the rotation of the working tool is an electric motor, transmitting movement through a two-stage mechanism, which allows to obtain two speeds. The desktop of this homemade device can be adjusted in height. Many of those who made their own copy milling machine, note that when changing modes of operation, such equipment begins to show a lot of shortcomings. The most common of these shortcomings are the vibrations of the machine frame, the curvature of the workpiece and its deflection, poor copying, etc. To avoid such problems, it is best to make the copy-milling device highly specialized and immediately set it up to process the same type of workpiece. This is explained by the fact that it is almost impossible to take into account all the shortcomings that will arise from universal equipment when changing modes of operation.

Milling machines with the ability to copy irreplaceable where you need to make parts in full accordance with the existing template. At the same time, the equipment will equally cope with the production of a small or impressive batch of wood products. As well as the CNC milling machine, this device is used in large-scale production, so it is popular both in private workshops and in large woodworking plants. Copy-milling units are able to produce a product that in its shape and size fully corresponds to the original sample, which is achieved by automatically moving the cutter along a predetermined path. The main advantage, which has a copy-milling machine, - high speed of processing parts, regardless of size and configuration. Scope of applicationA copy milling machine, also known in the professional environment as a duplicarver, is equally used for the manufacture of solid or flat pieces of wood, and its operation is similar to the operation of equipment equipped with a CNC system. Separate samples provide the ability to process wood blanks using a copier, which is a bulk model. Often used in the carpentry sphere, an engraving machine that incorporates a copying mechanism in its design is used to solve the following tasks:

Given that copying milling machines easily cope with the creation of decorative parts of complex configuration, such equipment is often found in the furniture industry.

Functional featuresThe design and filling of the copy-milling machine make it possible to achieve high speed of work when processing even complex parts. The main element of such units is a milling cutter. The cutting tool, in addition to the formation of wooden parts, is also used when working with metal products. The milling cutter cuts the necessary part along the contour or surface, which the copier mechanism initially sets. Communication between the cutting element and the control system over the correct execution of the process here takes place with the help of hydraulics and pneumatics. Most often, household machines for wood of this type are equipped with a mechanical system for supplying the workpiece and controlling construction nodes. A flat pattern, a previously created reference model, various contour drawings or photo cells are used as a copier, and the sample is chosen depending on the production features or at the request of the master. Sample patterns are made from any material, be it plastic, wood or metal. Focusing on the requirements of the modern carpentry sphere, many manufacturers are completing copying and milling machines with a CNC device, which turns the unit into a universal device. The copy milling machine functions according to the following principle: a template is installed to which the controller is connected, and the specified shape parameters are transmitted to the cutting element via a communication mechanism.

Types of equipmentDepending on the type of drive installed on the machine, the equipment is divided into the following types:

Also, copy milling machines are classified according to the degree of automation of the workflow, and the more advanced options are present in a particular model, the higher its price tag. It is worth noting that the template method of cutting wood initially implies an automatic observance of the torch movement trajectory, so the installation of CNC is absolutely not necessary here and, rather, is a tribute to the new technologies that have proven to be the most effective. Is it possible to create a copy milling machine by myself?Today on the market of joinery equipment there is no shortage of machines, but their rather high cost does not always allow you to purchase such a unit to a home craftsman. The device will pay off with its intensive use no earlier than in 5 years, and then only on an industrial scale. Now that you have learned about the characteristics of pantographs and know what it is and where it is used, you can try to make a copy milling machine yourself. Of course, the device of handicraft production is inferior in terms of performance of factory samples. Also, the masters do not recommend reworking a conventional mill in a copying unit, but advise to assemble from scratch.

Before you make a machine, select the appropriate scheme of its assembly, as a rule, includes several mandatory elements:

Change the mode of milling here by adjusting the height of the table top. The milling head is driven by an electric drive, while the equipment is often supplied with a speed regulator. Pantographs can be made of wood, although this option will not differ in high accuracy due to the looped connection of individual elements, which is characterized by backlash. As for metal drawing machines, they can operate at different scales, but they do not cope with the manufacture of bulk products. Unfortunately, milling on a self-made copying machine does not always allow you to get perfectly accurate part dimensions, besides, the finished product can have significant flaws. Such negative effects are primarily due to the vibration of the working surface, which is almost impossible to neutralize. Also, it is not always possible to avoid various flaws at the time of changing the direction of movement of the cutter. On top of this, there is an internal stress of the wooden workpiece, which leads to its curvature. Taking into account the shortcomings of homemade, the only significant advantage of which is the affordable price of components, it is recommended to resort to its help solely to create the same type of parts in the framework of narrow-profile production. Making a simple do-it-yourself copy machine at first glance seems like an easily accomplished task. The network has a lot of photos of finished designs that are impressive for their originality and ease of manufacture. Many people want to do something like that. But when the self-made copying machine is assembled, everything turns out to be not so smooth. Copy machines come with milling and turning. The prevalence of the first place is exactly milling and copying machines. They are more functional and allow you to get not only round copies, but also copies of arbitrary shape. About them and will be discussed in this article. The biggest misfortune of a milling and copying machine assembled at home is backlash and vibration. Many home craftsmen complain that when copying a sample, the resulting product has many inconsistencies and flaws that appeared when changing the direction of the molding cutter and the jitter of the support structure. In addition, the distortions of the curvature and deflection of the workpiece, associated with an increase in internal stress due to wood sampling, are added. Therefore, making a copying machine it is impossible to immediately avoid all the shortcomings. As a rule, after assembly, it is necessary to bring the design to acceptable parameters for some time. In any case, it is better to make a homemade copying machine, not universal, but narrow-profile, that is, optimized for the manufacture of specific products necessary for you. For example, to efficiently manufacture the wooden part of the gun, the propeller screw and the volumetric text, different technical solutions are needed, and if they are combined in one machine, then side effects can occur that are difficult to fix. Therefore, it is more practical to assemble machines for a specific task. Such an approach would avoid many difficulties and unnecessary costs. Also an important factor is the size of the machine. The more billet you plan to process, the more massive the structure should be. Vibrations transmitted from the cutter drive should be absorbed by the mass of the machine supporting structure. And the guide axles must not only withstand the load, but also have a safety margin so that they do not bend. With an independent design of a milling and copying machine, the optimal parameters for a smooth course of the cutter are selected experimentally.

Now make a copy, for example, the volume of the inscription is not difficult. You can also create a template for creating 3D text yourself. For this, you will need a printed sketch, a pair of cardboard sheets, glue and a stationery knife. A sheet with a sketch and cardboard stick together with each other so that the paper is not wrinkled. After drying with the edge of a stationery knife, carefully cut out the letters exactly according to the sketch. A template height of 2 mm is usually sufficient so that the probe does not slide off. Download a copy machine circuit Recent Entries: Duplikarver copy milling machineCopy-milling machine "Duplikarver" is designed for wood carving, copying sculptures and plane-relief products. To date, it has no analogues in the Russian market in terms of price-quality, and has received wide recognition among professionals and those who are just beginning to learn carving. The machines comply with the requirements of the Technical Regulations of the Customs Union TR TS 010/2011 “On Safety of Machines and Equipment” and have a declaration of conformity registered in the Federal Service for Accreditation (Rosakkreditatsii) under the Ministry of Economic Development of the Russian Federation. Registration number of the declaration of conformity: EAEU N RU D-RU.AB93.V.06056 Our company produces three models of machine tools. Duplikarver-1 and Duplikarver-2 allow you to perform two types of thread.

Duplikarver-3 retained all the possibilities Duplikarvera-2 and acquired a completely new. Now it became possible to execute a long volumetric thread.

The working tool of the machine is a high quality mill, produced in Germany. The control system allows you to smoothly change the speed of rotation of the cutter from 10,000 to 30,000 rpm. The machine works very reliably and accurately. You can master the techniques of working on it quite quickly, within a few days. The machine delivers real pleasure from the results of their work. The payback period is one month. Start browsing our site with a photo gallery of work, watch video clips, and you will get an idea of the capabilities of the Duplikarver copy milling machine. The copy milling machine for wood is a universal equipment designed to copy products in two- and three-dimensional format. This unit can copy the finished product two-dimensional type, as well as using special copiers and three-dimensional models. In addition, the technique is often used to engrave profiles and a variety of decorative elements. Also, a copying and milling machine for wood can be “entrusted” with simple traditional milling works, with which it is able to cope on a par with traditional milling machines.

This technique is inherently unique, since with its rather primitive device it is able to copy quite complex structures, including very delicate manual work. Such machines can be found at various enterprises, including large industrial facilities of large-scale production. Copy milling machine specializes in milling curved parts. This is done by copying from a template. Copy - milling machine for wood DIYIt is the templates that make it possible to make the process as accurate as possible, negating the manual work and, accordingly, the human factor. This feature of the technique is a guarantee that the parts obtained will be identical, and their shape will be the same. In this case, the master can use one template for all parts, or use already made parts as a template. In fact, each piece produced on such equipment can act as a sample, which confirms the amazing accuracy of the technique. If this is not enough for you, you can improve the accuracy parameter of your machine. To do this, it should be equipped with a special copying device. It is called the pantograph and is designed for extremely accurate transmission of the movement of the copying head to the main device processing the workpiece. If the template has a lot of "thin" parts - it makes sense to choose a copy-milling machine for wood, having as an option a pantograph. Design featuresThis unit allows you to process profiles or terrain. Processing is carried out with a special tool made of hard alloys. We are talking about cutters. The cutter repeats the movements of the copier - a device that reproduces the outlines of the pattern. This master device is completed with a mechanical or other connection with the tracking system responsible for the tool movement path.

What can perform the functions of a copier for such a machine? This can be a three-dimensional or flat sample, a contour drawing or a reference model. A special probe, in fact, encircles the contours of the workpiece, which are transmitted to the tool. In some modern units, instead of a probe, a photocell can be used, characterized by increased accuracy. Pantograph - an important element of the copy-milling machine for wood. Its design includes a special guide pin. He moves on the copier, accurately fixing any geometric features of the figure. The proportions of the shoulders of the pantograph determine the relative size of the final result. Classification of copy-milling machinesToday it is possible to share all the machines on the market according to a variety of parameters. By drive type, the following units can be distinguished:

There are also such units that differ from each other in the level of automation:

findings

Copy milling machines occupy an honorable place in the woodworking industry. Without them, the manufacture of parts with complex relief would take a lot of time. With the advent of such a technique, enterprise productivity increases tenfold. That is why the purchase of such a machine can be a very valuable investment for the master. COPIER a, m. copier & gt; him copieren, Kopiershablone. A detail of a copying machine that transmits movement to a tool that reproduces a given surface profile on the workpiece, corresponding to the profile of the copier. SIS 1985. Copier processing. Leping 1 738. || How does the & LT; cutlet automat & GT ;. The disk with the pistons rotates, the piston rods rest on the copier below, as if rolling on the copier now uphill, now from the mountain. Therefore, the pistons themselves then rise above the projections of the copier, then lowering under the action of the spring. The copier can be rotated 180 ° by the handle. PIO 1997 2 43. - Lex. SIS 1979: copy / ... Copier`Big Encyclopedic Polytechnic Dictionary` copier`Russian spelling dictionary` a cop Russian spelling dictionary. / The Russian Academy of Sciences. Inst. Rus. Homemade Copy MachineV. Vinogradov. - M .: "Azbukovnik." V. V. Lopatin (executive editor), B. Z. Bukchin, N. A. Eskova, et al. 1999. Copier` Efremov's Explanatory Dictionary` A detail of a copying machine that transmits movement to an instrument that reproduces through a blank given by a template, drawing, etc. profile. (it. Kopierschablone) - detail copier, having a shaped profile (shaped ruler, cam, washer, etc.). Big encyclopedic polytechnical dictionary2004 CopierPage 1 The copier consists of a copier mounted on the moving part of the device, along which the roller of the drive bracket slides from below, fixedly mounted on the vertical guides of the machine. Copier works as follows. Both cavities communicate with each other, for which a hole is made in the piston. The hydraulic cylinder rod tl tr mount, and the cylinder tzd 1 p still. Copiers are made either as adaptations to existing machines (turning, milling, etc.), or they are organically embedded in them and form copy machines or semi-automatic machines. The copier can be mechanical, electromechanical, hydraulic, and the rotation of the spindle unit, of the table is one or two-index. Copiers can be installed on horizontal milling machines. A copier (fig. 73) is used for machining shaped surfaces with a sufficiently high accuracy. The copier of this machine works by inductive method. Pattern processing copiers can provide accuracy up to 0 02 mm. Do-it-yourself copy milling machine - create reliable equipment!The copier consists of three separate parts: the copier posts (right and left), the sensor slide and the sensor slide. Racks of the copier are installed on the caliper case and can move along the rails of the caliper to install the copier when setting up the machine. Copier is designed for longitudinal and transverse copying. To do this, a special holder with a roller, which rests on the copying ruler, is fastened on the revolving head. The copy ruler is set at the required angle to the horizontal and fixed in this position. Copiers of this type (Fig. 6.25) are equipped with two piston engines: with an inclined washer 6 - for the lead and 5 - for the tracking movement. Copiers are rational to use on rotary machines. Single-rack carousel machines model 1541 of the Sedin factory, as well as new domestic machines are equipped with copiers. Foreign firms Schiess, Froep, Gidings, Webster and Bennett and others manufacture machines of corresponding designs that allow the installation of copiers. Copiers can be of mechanical, electrical and hydraulic action. The holder 6 with a cam 7 is fixed in the turret socket, and the case 2 is fixed in the tool holder of the side slide. Cutter / machined profile. Pages: 1 2 3 4 |

Popular:

New

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects

- Kerner - so that the drill does not slip off!

- Objects of inanimate nature Examples of the influence of inanimate nature factors on plants

- Finishing joinery

- Block breakdown in AutoCAD - simple and effective teams from practitioners

Creating a drawing machine for wood copying and designing it, you must do everything depending on the parts that will be made on it. So, in order to mill long workpieces or to perform engraving works, a completely different way of securing workpieces and the type of desktop are required.

Creating a drawing machine for wood copying and designing it, you must do everything depending on the parts that will be made on it. So, in order to mill long workpieces or to perform engraving works, a completely different way of securing workpieces and the type of desktop are required.

The principle of operation of the milling and copying machine is as follows: a milling cutter is installed on the moving frame for sampling wood and the probe, which is driven by the original. The frame is lowered to a wooden blank, and excess wood is removed by a mill. The whole point of the design is to provide simultaneous movement of the cutter and probe in three planes, as well as rotation around the transverse axis. To do this, use metal guides or wooden hinge systems. Wood absorbs vibrations better, is easier to process and less costly. The video at the bottom of the page shows a homemade copy machine for creating flat-relief images and three-dimensional inscriptions with a non-standard way of moving in space. Moreover, this design provides for a two-fold reduction in scale. Download drawings milling and copying machine can be one archive at the bottom of the page.

The principle of operation of the milling and copying machine is as follows: a milling cutter is installed on the moving frame for sampling wood and the probe, which is driven by the original. The frame is lowered to a wooden blank, and excess wood is removed by a mill. The whole point of the design is to provide simultaneous movement of the cutter and probe in three planes, as well as rotation around the transverse axis. To do this, use metal guides or wooden hinge systems. Wood absorbs vibrations better, is easier to process and less costly. The video at the bottom of the page shows a homemade copy machine for creating flat-relief images and three-dimensional inscriptions with a non-standard way of moving in space. Moreover, this design provides for a two-fold reduction in scale. Download drawings milling and copying machine can be one archive at the bottom of the page.