Site sections

Editor's Choice:

- Installation options for drywall in the bathroom

- Court decision on recovery from the management company of the amount of damage to the gulf of the apartment

- Living room and children in the same room: options for partitions

- Top sofa upholstery rating: customer reviews

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

- Surface grit - tooling work

- Maximum load on the balcony slab: how much can a balcony withstand in a panel house?

Advertising

| The sequence of the markup. Marking wood blanks Marking procedure sequence of operations |

Preview:Summary of the second generation of GEF. Technology 5 class. №5 Technological map of the lesson Information about the teacher: Buts Denis Aleksandrovich Class: 5 Textbook (CMD): N.V. Tit, V.D. Simonenko The topic of the lesson: “ Marking wood blanks. Types of measuring and marking tools used in the manufacture of wood products. Etc. Marking wood blanks; methods of using measuring and marking tools». Type of lesson: combined Equipment: Multimedia equipment.Marking tools.Technology textbook V.D. Simonenko. Planned results

Basic concepts: marking, base plate, base edge, allowance, pattern. Stage 1 motivation (self-determination to activities) -org. moment, we create a problem showing a slide with the image of marking tools and a sequence of marking parts from wood. Question: What tools for marking wood pieces do you know? Why does the workpiece marking start from the base layer or from the base edge?

In order to update knowledge, a brief conversation with students is held, the entrance of which asks the following questions: How are parts with curved contours marked out? (Informative coding - acquire new knowledge in the process of observation and reasoning) What is allowance? - (Regulatory CRAs - independently select an allowance for the workpiece.) Why seam allowance when planing is usually prescribed up to 5 mm, and when sawing about 10 mm? - (cognitive AUD - the correct selection of allowance). In order to update knowledge, students are interviewed during which the following questions are asked: 1.What is a surface gage? (Informative coding - acquire new knowledge in the process of observation and reasoning) 2. What is a gauge for? (Regulatory EAA - independently set the specified size). 3.What is the base layer? (Educational coding - search and select the necessary information to solve the educational problem - in the textbook, encyclopedia, the Internet.) The formulation of the topic of the lesson. What do you think we will learn today? Having clarified the children's opinion, the teacher specifies how correctly and with what tools they mark up the workpiece, and also demonstrates the sequence of detail marking (updating students' knowledge, regulatory ECD - goal setting) Practical work The teacher organizes the actualization of ways to study actions sufficient to build new knowledge. Trial action (task) - Drawing markup. One - applies the markup using a ruler pencil and a square The second one - marks using gauge and roulette Third - applies markup using compass and template (UUD communicative - cooperation, fulfillment of different roles in the group) The teacher checks the correctness of the assignment, identifying difficulties in the trial action. Fixing difficulties: Incorrect use of tools for marking workpieces (solutions to the problem) Out of the difficulty: Once again, the teacher shows how to correctly mark up the workpiece with the help of tools for marking, thereby organizing students to investigate the problem situation (UUD - communicative, joint solutions to the problem) 3. Reflection of educational activity At this stage of summarizing the lesson, the teacher asks the children questions, answering which he can judge about the mastering of this material. Questions: - What is allowance? What new knowledge have you gained for yourself? Can the knowledge acquired today be useful in life? The teacher invites the boys to evaluate their work in the classroom. (UWP personal - an adequate understanding of the reasons for success / non-success in learning activities.) House. the task : make markup on the workpiece. Plan - lesson outline Lesson # 5 "Marking wood blanks" purpose the lesson: familiarize schoolchildren with the “markup” technological operation, tools for marking, the rules and sequence of marking; teach them how to mark up pieces of wood and wood-based materials; develop accuracy, accuracy of execution, respect for wood. Goals: Educational: introduce the markup operation, markup tools, markup techniques, markup blanks using a template. Developmental: learn how to perform cost-effective marking of blanks. Educational: educate accuracy, accuracy. Didactic learning tools: drawings of wood parts for practical work No. 5, drawing tools, wood blanks and tools for marking; textbook (§ 7), RT, PC. LESSON TYPE: Combined Lesson Methods: story, conversation, demonstration of visual aids, work with the book, practical work. Formed versatile learning activities: personal, cognitive, communicative. Anchor concepts: marking, joiner square, gauge, Malka, the base edge, the base layer, allowance, pattern. Planned learning outcomes. Personal results Subject results Meta-Subject results The desire to improve their knowledge and skills in the subject "Technology". Show interest in classes practical activity, respectful attitude to work, express a desire to learn to meet promising needs. Get acquainted with the types of control and measuring marking tools. Learn how to perform economical techniques markup blanks Educational ccd: under the guidance of a teacher and in collaboration with classmates, draw conclusions on the basis of the information received; Make simple practical decisions, observe Regulatory CRAs: be able to collaborate with the teacher set new learning objectives; Take cognitive initiative in educational cooperation; Memorize instructions, plan, control Communication uud: be able to reason, hear, listen and understand the interlocutor, plan and coordinate jointly, correctly express your thoughts Technological card with the methodical structure of the lesson 80min Stage goal Teacher activity Student activities Wud 1. Organizational stage 2 min. Student activation Greetings class. Test class readiness to conduct classes Greeting teachers, control their readiness for the upcoming lesson. Personal : mobilization of attention respect for others Regulatory : lesson planning Cognitive: procedure and organization of the lesson on technology Communicative : mutual cooperation of the teacher and students in the lesson 2 Knowledge update -5 min Identify the level of knowledge and readiness to learn new material. Analyze the knowledge gained: Workplace carpenter? His device? - manufacturing process? Technological operation? - technological process? - routing? Joiner's tool? To carry out the exit to the task, which causes cognitive difficulty: where do they start manufacturing products from wood? Participate in the dialogue and discussion of problematic issues, formulate their own opinions and argue it. Pupils should realize why and why they need to study this topic. Personal : awareness of their capabilities. Regulatory : ability to plan your work. Cognitive : skills to work with information, analyze, compare, highlight the main thing. Communicative : cooperation and communication of the teacher and students. 3. Setting goals and objectives of the lesson. Motivation of students learning activities -3 min. To create conditions for the emergence of an internal need for inclusion in educational activities. Inform students about the lesson: - marking of pieces of wood. Types of measuring and marking tools used in the manufacture of wood products. Answer the teacher's questions, discuss them. Formulate the goal of the lesson, defining the boundaries of knowledge and ignorance. Make a plan to achieve the goal of the lesson and determine the algorithm of their actions. Personal : mobilization of attention, the desire to learn new Regulatory : goal setting, activity planning Cognitive: ability to work with information, analyze, compare, highlight the main thing Communicative : proactive cooperation in the search, selection and analysis of information. 4. Primary learning new knowledge 10 min. Organize a meaningful perception of new information. Conducts an explanation of the new material, helps to parse the information: At the beginning of the lesson, the teacher demonstrates to the students the tools for marking wood blanks, their design and methods for using them, focusing on the rules for safe work with compasses and surface gauge; -allowance on processing for planing up to 5 mm, and for sawing about 10 mm; He proposes to consider Fig. 20 (p. 30) from the textbook and comments on each stage. Pays attention when selecting a material and its marking, the allowance for processing should be minimal, since it saves the consumption of wood materials. Participate in the conversation; formulate conclusions, make notes in a workbook. pupils must learn that not high-quality marking of the workpiece will lead to the manufacture of defective parts. Personal : awareness of their capabilities; Regulatory : ability to plan the stages of the future project. Cognitive : extract the necessary information from the listened, structure knowledge. Communicative : engage in dialogue, with confidence in the completeness and accuracy of the expression of their thoughts. 5. Primary understanding test 7 min. Contribute to the emotional state and the development of cognitive interest to the topic It proposes to perform step 1 of task 5 in the workbook: to determine the procedure for performing actions when marking up the part shown in Figure 9 (p.16) from the textbook. The correct arrangement of numbers: 1, 5, 2, 6, 4, 7, 3. Perform the task in notebooks, formulate conclusions. Personal : Regulatory : analyze and establish a logical sequence in answering questions. Communicative : listen, hear and analyze the opinions of the interlocutors Cognitive : apply this knowledge when choosing a theme for your creative project. 6. Initial fixation 40 min Provide meaningful and assimilation and consolidation of knowledge on the topic of employment Practical work №5 "Marking wood blanks" The analysis of the marking of wood blanks by the students revealed a typical mistake that they make: the lines drawn along a ruler or a square, compasses and a surface gauge will be uneven and intermittent. In this regard, explain the following rules to them: 1) when drawing a line on a ruler, the pencil should be pressed to the edge of the ruler (located at an angle of 70-75 ° to the plane of the part) and tilted in the direction of motion; 2) when drawing a line with the help of a square or pulley, the gauge pad should be pressed tightly against the edge of the workpiece, and the screw of the bead should be well tightened; 3) when marking the surface gauge, the workpiece must be fixed in the workbench clamp, and when drawing the line the end of the pad should be constantly pressed to the base plate and not press hard on the needle; 4) when carrying out an arc or a circle with a compass, it is slightly tilted in the direction of movement, resting on a leg with a needle. The teacher constantly monitors the compliance of students with the rules of safe work drawing and marking tools. Students mark the blanks issued by the teacher, or the workpiece details of their design products. Listen carefully to the instruction teachers. Follow the rules of TB. Markup control. Personal : awareness of their learning opportunities; Regulatory : self-organization of educational activities, control, evaluation, correction of their knowledge. Cognitive : ability to structure knowledge. the choice of the most effective ways to solve problems compliance with safety standards and rules of cognitive-labor activity and creative labor. Communicative : organize learning interaction with each other, and in general in a team. 7. Control of learning, discussion of errors and their correction 8 min Identify common mistakes and possible gaps in knowledge and skills, through their elimination, correction and improvement Analyzes the work of students during the lesson, advises on issues arising during the discussion, advises, helps. Teaches how to monitor and self-assess activities. Develops the ability of students to independently find and correct errors, to determine the degree of success. At the end of the lesson, students performtask "Check yourself" from the workbook. The correct answers to the task "Check yourself" Statement Before Not The teacher formulates the conclusions, summarizes the joint and individual activities, makes marks for the lesson. The final assessment of the lesson should be comprehensive, taking into account the quality of the marking of the workpiece, as well as the results of task 5 of the workbook They present the results of mastering the material in the classroom and individually, exercise control (with the help of the teacher, use forms of self-control and mutual control), formulate difficulties and carry out correction, possible mistakes made. Together with the teacher, draw conclusions on the nomu material. Personal : Regulatory : control, correction, selection and awareness of what is still to be learned, awareness of the quality and level of learning of the educational material; Cognitive : ability to structure knowledge, the choice of the most effective ways in answering questions; Communicative: partner behavior management - control, correction, evaluation of partner actions. 8. Information about homework, briefing on its implementation 3 minutes Homework Information The teacher advises. Three levels of homework: Standard minimum (reproductive level) Constructive - Creative 1. Answer the questions given at the end of §7. 2. Find on the Internet and other sources of information or come up with the very form of the template with which you can mark the preparation of cutting boards. In the next lesson, show the template to the teacher to assess the possibility of its placement in the library of the training workshop. Realize the variability of homework, choose a feasible version of its implementation and work on it. Personality: awareness of the importance of learning the subject; 9. Reflection (summarizing lesson) 2 min Give a qualitative assessment of the class and individual students. Initiate the reflection of students about their psycho-emotional state, the motivation of their activities and interaction with the teacher and classmates in the last lesson. The teacher organizes the reflection of educational activities in the classroom. What have you learned in class? What new concepts have you learned today? Where can I apply this knowledge in practice? Why do you need to know this material? What difficulties did you have? Give an analysis of their activities in the classroom. Encourages students to formulate their response in the form of a telegram, SMS message, a complete sentence. You can ask students to argue their answer. 1.In class I worked actively / passively. 2. I am satisfied / displeased with my lesson work 3. The lesson for me seemed short / long 4. For the lesson I am not tired / tired 5. My mood is better / worse 6. The lesson material was clear / not clear to me useful / useless interesting / boring 7. Homework seems easy to me interesting / not interesting They answer the teacher's questions, analyze the work done by them in the classroom, carry out self-assessment, discuss it, draw conclusions. Personal : awareness of the interest and importance of studying the subject; Regulatory : self-assessment of activities in the classroom; Cognitive : the development of cognitive interest in the subject; Communicative: ability to listen and conduct dialogue; Markup preparation. Before proceeding with the markup, carefully check the workpiece: if there are shells, cracks, broken corners and other defects. Then the workpiece is cleaned of dirt and dust. Further, they study in detail the drawing of the future part and outline the order of marking: they determine in which position the part will be mounted on the plate and in what sequence the marking lines will be drawn. In order to choose the correct way of marking, it is necessary to clearly represent the purpose of the marked part, its role in the machine. Therefore, it should, in addition to the drawing of the marking part, also examine the assembly drawing and become familiar with the technology of manufacturing the part. Select base when marking. The correct choice of bases in the markup determines the quality of the markup. The choice of marking bases depends on the design features and technology of manufacturing parts. Base is selected, guided by the following rules:

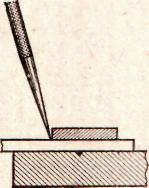

After the base has been mapped out, the marking order, the location and the installation of the marking part on the plate are determined and the necessary marking tools and fixtures are selected. Installation of the workpiece on the marking plate. Before installing the workpiece on the marking plate, those places where the marking risks will be applied are painted with chalk, paint, varnish or copper sulphate. When installing only the first position of the workpiece on the plate is independent, and all other provisions depend on the first. Therefore, the first position of the workpiece must be chosen so that it is convenient to start marking from the surface or the center line adopted for the base. The workpiece is installed on the plate not in an arbitrary position, but in such a way that one of its main axes is parallel to the plane of the marking plate. There are usually three such axes on the workpiece: in length, width and height. Details of large dimensions that cannot be turned over are marked with reamers and marking squares. Install reismas on the marking plate and moving it, put marking lines. Tips for marking markings. With the spatial marking of blanks, it is necessary to apply horizontal, vertical and oblique risks. These denominations are retained even when turning the workpiece during the marking process. If, for example, the risks during the initial position of the workpiece were held horizontally, then, while turning the workpiece through 90 °, they became vertical, so that there was no confusion, they continue to be called horizontal. In addition to the main marking risks, parallel to them at a distance of 5-7 mm they carry out control risks, which serve to check the installation of the workpiece with further processing, as well as to enable processing in cases where the marking risk has somehow disappeared. When marking on the slab, horizontal risks are drawn with a reamer set to the appropriate size. Reismas move parallel to the plane of the marking plate, slightly pressing it with the base to the plate. At the same time, the reismas needle should be directed obliquely towards the marked plane in the direction of movement at an angle of 75-80 °. The pressure of the needle on the workpiece should be uniform. The marking of vertical scratches can be performed in three ways: by marking square, reismas with rotated workpiece 90 °, reamers from marking prisms without rotation of the workpiece. The inclined lines are applied by the scriber by turning, details on the protractor installed at the required angle. When marking the hollow parts (Fig. 220), a wooden center bar is hammered into them, and then a metal bar made of brass or lead is filled into it to support the compass leg. If the plank is made of solid wood, it is possible not to tamper with the metal bar. The markup further lead in the usual way. Fig. 220. Marking holes Marking of cylindrical parts. The billet is placed on a plate on one or two prisms and the horizontality of the generatrix of the cylindrical surface relative to the surface of the marking plate is checked (Fig. 221). Short cylindrical parts mounted on a single prism.

Fig. 221. Marking keyway with the use of plane-parallel end measures of length (tiles): The marking of the keyway on the roller must be performed in this order:

Pattern markup. It is used in case of wear or breakage of parts and in the absence of a drawing for the manufacture of a new one. In such cases, the sample is a worn or broken part. If the part is flat, then after thorough cleaning it is superimposed on the workpiece and stroke lines are laid on it. In those cases when it is impossible to impose a sample on the workpiece, it is placed side by side and all dimensions are transferred from it to the workpiece with a reamer. When removing the dimensions from the sample, take into account the wear of the sample (old part), and also check whether it is damaged, if it is warped, if the protrusions are broken off, etc. Location Markup. Produced in cases where the nature of the compounds required to collect parts on the spot. For this, one of the parts is marked, holes are drilled in it; in the second part, the holes are drilled after the first is laid on it, which is like a template with respect to the second. Rational markup techniques. When working with flightmasom, each installation of the scriber in height takes a lot of time. When marking a batch of identical parts, several flight points are used that are pre-set to a certain size. Scriber need to install in a certain position only once, and then consistently transfer them to the marked workpiece. From time to time the installation of the scriber should be checked. If there is only one reisma at the disposal of the locksmith, it is recommended that you first transfer one set size (Fig. 222) to all the workpieces, then the second, third, and so on.

Fig. 222. Marking the batch of parts by one flight Marriage Marking. The most frequent types of defects with spatial markup are:

Questions for self-test

Before proceeding to the markup, carefully check the workpiece (if there are any shells, cracks, corners and other defects), then it is cleaned of dirt and dust. Further, they study in detail the drawing of the future part and outline the order of marking: they determine in which positions the blank will be mounted on the plate, and in what sequence the marking lines will be drawn. In order to choose the correct way of marking, it is necessary to clearly represent the purpose of the part, its role in the car. Therefore, in addition to the drawing of the marking part, it is also necessary to study the assembly drawing and become familiar with the technology of manufacturing the part. Select base when marking. The correct choice of the base when marking determines the quality of the latter. The choice of marking bases depends on the design features and technology of manufacturing parts. Base choose, guided by the following rules:

All sizes are applied from one surface or from one line taken as a base.. After the base has been mapped out, the marking order, the location and the installation of the marked workpiece on the slab are determined and the necessary marking tools and fixtures are selected. Installation of the workpiece on the markingthe stove. Before installing the workpiece on the marking plate, those places where the marking risks will be applied are painted with chalk, paint, varnish or copper sulphate. When installing only the first position of the workpiece on the plate is independent, and all other provisions depend on the first. Therefore, the first position of the workpiece must be chosen so that it is convenient to start marking from the surface or the center line adopted for the base. The workpiece is not installed on the plate in an arbitrary position, but in such a way that one of its main axes is parallel to the surface of the marking plate. There are usually three such axes on the workpiece - in length, width and height. Marking lines.With the spatial marking of blanks, it is necessary to apply horizontal, vertical and oblique risks. These denominations are retained even after the workpiece is rotated during the marking process. If, for example, the risks in the initial position of the workpiece were held horizontally, they, although they. after turning the workpiece 90 °, they became vertical, to avoid confusion, continue to be called horizontal. In addition to the main marking risks, parallel to them, at a distance of 5 ... 7 mm, they use colored pencil to control risks that serve to check the installation of the workpiece during further processing, as well as for processing in cases where the risk has somehow disappeared. When marking on the slab, horizontal risks are drawn with a reamers set to an appropriate size. Reismas move parallel to the surface of the marking plate, slightly pressing it with the base to the plate. At the same time, the needle of reismas should be directed obliquely towards the marked surface in the direction of movement at an angle of 75 ... 80 0, and press the needle evenly on the workpiece. Marking vertical risok can be done in three ways:

The inclined lines are applied by a scriber, turning the workpiece along the protractor mounted at the required angle. Workpieces of large sizes that cannot be turned over are marked with reamers and marking squares. Install reismas on the marking plate and moving it, put marking lines.

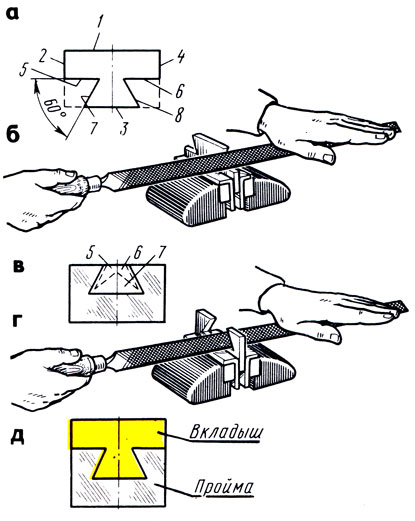

Municipal budgetary educational institution secondary School № 70 Summary of the lesson: « Marking wood blanks " Compiled by: technology teacher Lipetsk 2014 Purpose:teach students how to mark the details of wood. Equipment:wooden blanks, drawings, marking tools (pencils, rulers, squares, compasses, gauges, templates, etc.). During the classes I. Repetition of the material covered. 1. Talk on: "Name the assignment of the flow chart. "What is called a stock? "What is called a process operation? 2. Posting topics and objectives of the lesson. Ii. Presentation of program material. 1. Introduction to the topic of the lesson. Teacher. Do you have material from which I would like to make a conceived product. There are tools to get started: cut, drill, trim, etc. "Can I proceed? "Will you have a good, high-quality, beautiful job? "Why? (Listened to the views of students.) The guys, to embody any conceived case and get such a product that would be pleasing to the eye, consistent with the required size and proper processing, you need to think carefully about everything. What do you think, where to start? (Presumptive answers from students.) Before making parts of the desired shape, they are marked out using measuring and marking tools. Write down what the term "markup" means. Markup - this drawing contour lines on the workpiece. When marking parts of rectangular shape, a ruler and a square are used. The teacher demonstrates the techniques of rectangular marking. (See Appendices, Fig. 17.) 2. The sequence of markup actions. 1 .Before marking, one of the edges of the workpiece is cut down or pressed exactly in a straight line. 2 Parallel marking lines can be made using surface gauge. (See Appendices, fig. 18, 19.)

3. Circles and arcs are drawn with a compass on the marked blank. Then the center is marked. 4. The radius is plotted on the ruler. 5 .Apherding the radius a circle is outlined. Consider a special kind of markup, which is pattern markup. Pattern marking is used if it is necessary to manufacture several identical parts of complex shape. Templates for these identical parts are made of wood, metal, plastic. What do you think the role of patterns in the overall manufacturing process? (Student answers.) Layout on the template allows you to quickly and accurately draw the desired shape of the part. The teacher shows the acceptance of markup on the template. Iii. Practical work. Execution of tasks: 1. Using the marking tools, mark up the workpiece parts according to the drawings proposed by the teacher. 2. Mark the blank according to the template proposed by the teacher. Iv. The result of the lesson. |

| Read: |

|---|

Popular:

New

- Edit strip and sheet material

- Open lesson "editing, bending"

- Installation of staircases and platforms: general information

- Repair of pipes of water supply in the apartment Repair of steel pipes

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber

- Drawing on preparation of contours of future product

- Modern ways of cutting metal and its defects