Site sections

Editor's Choice:

- Alteration of "Khrushchev" dvushki almost treshku

- Paint the wallpaper with your own hands

- Installation options for drywall in the bathroom

- Court decision on recovery from the management company of the amount of damage to the gulf of the apartment

- Living room and children in the same room: options for partitions

- Top sofa upholstery rating: customer reviews

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

- Belts and sandriks, crackers and volutes - secret codes of architecture on the example of the old Saratov Sandriks in architecture

Advertising

| Pipe bending machines. Pipe bending machines Pipe bending machine for construction companies |

|

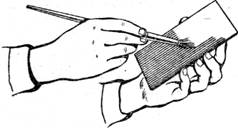

Pipe bending machine ВМС-23В it is intended for bending of gas-and-water pipes in a cold state without sanding. It consists of a cast frame, an electric motor with a gearbox and a working mechanism. Technical details Diameter of bent pipes Du, mm 15 - 32 Pipe bending six-position mechanism VMS-26A it is intended for bending of water gas pipelines in brackets, ducks or bends in a cold state without filler. It consists of a frame, a rocker mechanism, an electric motor with a gearbox, a plate and a slider. Technical details Diameter of bent pipes D y, mm - 15 and 20 Multi-position mechanism STD-102 it is intended for are flexible branches and semi-outlets from water gas pipes. It consists of a frame, a drive, a crank mechanism, a table with a slide and electrical equipment. Rollers are fixed on the table, sectors on the table slider correspond to the diameters of the pipes bent and the angle of their bending. Technical details Diameter of pipes Du, mm - 25-50 Pipe bending machine TGS-2 designed to bend water and gas pipes without filler. Technical details Diameter of flexible pipes Dy, mm - 50; 40; 32; 25; Machine STD-439 designed to bend water and gas pipes in a cold state without a mandrel. Technical details The diameter of the bent pipe Dy, mm - 15; 20; 25; 32 Six-position machine 26A it is intended for bending of water gas pipelines in branches, ducks and brackets. Technical details The diameter of the bent pipe Dy, mm - 15; 20 Mechanism STD-672 designed for the manufacture of sockets at the ends of water and gas pipes. Technical details The diameter of the processed pipe D, mm - 15; 20; 25 In a cold state, pipes are bent on manual and driven pipe-bending mechanisms. For manual pipe bending, Volnov machine tools are used, and for mechanized pipes, the mechanisms HF-16, HF-23B, HF-26, HF-28 and GSTM-21 are used. The internal diameter of the roller of the pipe bending mechanisms should correspond to the bend radius adopted in the calculation of the blank. Manual Volnova machines (Fig. 51) are designed for bending pipes with a diameter of up to 20 mm. The machine is attached to the workbench by means of the hub and plate 1. On one axis of the hub and plate there is a fixed roller pattern 6 with clamp 7. The movable roller 2 is fixed in bracket 4 with the handle 5. The pipe is bent around the fixed roller, therefore the radius of curvature of the bend approximately corresponds to the radius this video.

Fig. 51. Volnova machine: The pipe 5, which must be bent, is inserted between the rollers so that its end enters the collar 7. After that, with the handle 3, the bracket is turned around the non-movable roller 6 until the required bend is obtained, then it is returned to its original position and the pipe is removed. It is recommended to clamp the longer end of the pipe into the clamp, and to bend the short one. On the Volnova machine, bends, staples, ducks and kalachs without beading pipes with sand are bent. Volnov’s combined machines with double rollers are also used for bending pipes with a diameter of 15 and 20 mm on one machine and with triple rollers for pipes with a diameter of 15, 20 and 25 mm. The VMS-23V pipe bending machine (Fig. 52) is designed for bending steel water and gas pipes with a diameter of 15-32 mm. The machine consists of a cast bed 1, a gear 2 and a working mechanism 3 located on the upper part of the bed. On the working mechanism there are pyramidless fixed 4 and movable 5 rollers. Each pair of fixed and movable rollers serves to bend pipes of a certain diameter without machine changeover. A flanged electric motor is attached on the outer side of the frame, from which the working mechanism is rotated through a reducer, a bevel and a cylindrical gear, together with a moving roller pyramid.

Fig. 52 Pipe-bending machine ВМС-23В: The pipe intended for bending is brought into the clamp corresponding to its diameter. When turning on the machine, the movable roller moves around the stationary and bends the pipe. The mechanism Navy-26A is a multi-position high-speed mechanism used for bending bends, ducks, brackets with a diameter of 15 and 20 mm. At present, the serial production of the pipe-bending mechanism VMS-28, intended for bending pipes with a diameter of 15 to 32 mm, has begun. This mechanism is based on the mechanism of the Navy-23B and differs from it in that it has a hitchhiking, providing a bend at a given angle. Bending error not more than 5 °. The pipe bending mechanism GSTM-21 (Fig. 53) is designed for bending steel water and gas pipes with a diameter of 25 to 60 mm and seamless pipes with walls up to 4 mm thick, with a diameter of 34 to 89 mm in a cold state with the use of mandrels.

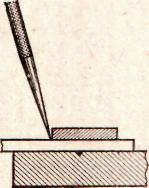

Fig. 53. GSTM-21 pipe bending machine: In the base1 of the GSTM-21 machine there is a worm pair and the main drive shaft. The rotation of the disc bending rollers 2 is transmitted from the electric motor 5 through the V-belt transmission and gearbox. The marked pipe is installed in a roller stream and secured with an eccentric clamp. Then screw 4 press the sliding interchangeable block placed in the rod 3. Next, turn on the electric motor and turn the clutch engaging handle. The bending roller begins to rotate, bends the pipe and at the same time tightens it from the mandrel. After bending the pipe to the specified angle, the machine automatically shuts down and the pipe is removed. The construction machine VMS-16 (fig. 54, a, b) is designed for cutting pipes with a diameter of 15-50 mm and cutting threads on them, as well as for bending pipes with a diameter of 25-50 mm using appropriate tools and devices.

Fig. 54. Construction equipment Navy-16: The VMS-16 construction unit is equipped with a gearbox, an electric motor / power 1.7 kW with a rotational speed of 1420 rpm. With the help of a worm pair located in box 2, the electric motor drives the hollow spindle to rotate. At one end of the spindle, a three-jawed chuck 3 is hardened, and on the other, a faceplate with three guide dies for the pipe. Spindle switch 8 can be reported right or left rotation. The mechanism is mounted on four detachable legs 7. Two retractable handles 5 serve to carry the mechanism, in addition, they are also used to rest the working tool. The quality of the bending of pipes depends on the skill of the operator, the choice of tools and accessories, as well as on which machine is selected for processing. The pipe bending machine can be manual, semi-automatic and automatic. When choosing a new or used pipe bending machine, it is necessary to take into account: the material of the pipe being bent, its wall thickness and outer diameter, the number and radius of bends. Important are the required quality of processing, and the necessary machine performance, and the financial capabilities of the buyer. Main selection criteriaIf you need to get a large bend radius (more than 5 pipe diameters) when machining aluminum profiles, channels, angles, etc., the best option would be a three-roll pipe bender. For bending products made of non-ferrous metal and stainless steel with a diameter of 6 to 22 mm used cutting machines and machines for forming ends. Such equipment is in demand in the production of heating, water and gas heating appliances, air conditioners and compressors. To create a bend with a small radius (less than 5 pipe diameters), a machine with a mandrel is needed. The rod with a flexible tip allows you to get a bend radius of 1.5 pipe diameters. In this case, folds from the inner side of the product are not formed. The profile can be processed in this way of any shape and material, including copper, aluminum and stainless steel. Hydraulic machines have a relatively low cost, but the speed and accuracy of processing will also be low. The semi-automatic machine bends a pipe with a radius equal to the radius of the bending head and is in demand when processing rectangular and square profiles, round pipes. It is suitable for mass production, not requiring high machine load, where high bending quality and low equipment cost are important. Single-head machines perform the bending of one radius. Multiheads allow you to create a straight section between the bends with the same or different radii of rounding. The equipment is equipped with a pusher through rollers, thanks to which it is possible to create smooth arcs, spirals, arches of a large radius. The machine can handle a pipe with a diameter of 103 mm. With increased quality requirements, equipment is used: bending heads, front or tail presses, and folding holders. Such items are made to order. Pipe Bending Machine ModelsNavy 23Such pipe bending machines are designed for cold bending products without mandrel and filler. On it process round pipes with a diameter up to 25 mm. When changing rollers can bend and profiles. Machine power: 2.8 kW. Included are nozzles for pipes ½ ″, ¾ ″, 1 ″, 11/2 ″, the average bend radius is 49 mm.

CNC pipe bender minimizes human participation in the production process CNCReliability and high performance are especially important in automated production lines. CNC machines are installed together with robotic arms and loading and unloading devices. The fully automatic 800 VGP machine bends pipes up to 80 mm. The direction of the bend, you can choose the left or right. VGP 3D software reduces the likelihood of rejects and reduces program editing time. Video review: pipe processing on a CNC pipe bender STG 45rIt serves for bending pipes by winding. It has an electro-hydraulic drive, is controlled in manual mode. The largest diameter of the processed pipe: 45 mm, bending angle: 190 °, power: 4 kW. CE 51Allows you to produce high-precision bending of the profile of water and gas pipes of various sizes, including with thin walls (by winding). Eliminates the appearance of kinks due to the presence of a flexible mandrel and fold-smoothing. The machine can work in automatic mode. The CNC device controls the linear and rotational movements of the workpiece. Maximum pipe size: 51 mm. Motor power: 1.5 kW. INSTANThe pipe bender is equipped with a hand-operated hydraulic actuator, it processes round bars, as well as gas and water pipes. When processing thin-walled products (the ratio of the wall thickness to its diameter should not exceed 0.06), the manufacturer recommends the use of dense sand packing.

High-performance machine UGS-6 / 1A UGS-6 / 1A MM3-3101№1ADesigned to handle a different type of profile. A specially designed roller allows you to automate the bending process as much as possible. On this high-performance machine, you can perform operations in automatic and manual mode. Its advantages:

IV 3429It is used for bending products in the cold way with and without mandrel (by winding on a bending roller). Bending radius: from 1.5 pipe diameter to 500 mm. Machine power: 7.5 kW, the largest diameter of the workpiece: 76 mm. Features of the machine:

Homemade pipe bender necessarily come in handy on the farm For processing pipes with a diameter of 25 mm, you can make a pipe bending machine with your own hands. It will take: a concrete slab, a drill for concrete and several metal pins. The procedure is as follows.

In conclusion, we conclude that the automatic pipe bending machine is indispensable in mass and mass production. The programming process makes it possible to see the finished product in a three-dimensional image. If you need a budget machine to get the folds of one radius, the best option would be equipment with hydraulic drive. And in order to bend several pipes, you can make an improvised device. The history of production at the Moscow Mechanical Plant No. 3 of pipe bending machines has been going on for more than 40 years, such machines have been manufactured since 1973. One of the first pipe-bending machines produced was the Naval Forces-23V and was already exported at that time. The machine had fixed and movable rollers of four sizes ½ ”, ¾”, 1 ”, 11/4” located pyramidally. The frequency of rotation of the bending tool - 4.28 rpm with an electric drive power of 3 kW. The machine was made in a cast-iron housing having dimensions of 1054x725x490. The narrow specialization of the machine did not allow to bend pipes with a diameter of 11/2 ”, 2”. The Navy-23B pipe bending machine was produced for about ten years until 1983. The next pipe bending machine manufactured by the Moscow Mechanical Plant No. 3 was STD-439, which has been produced since 1983. The machine as well as the previous one was made in a cast iron housing. To install it, a specially prepared foundation was required. The pipe bending machine was equipped with a worm gearbox and a working tool drive from an external gearing. The pads, like the previous machine, remained pyramidal, also the rollers had four sizes ½ ”, ¾”, 1 ”, 11/4” and did not allow the pipes to be bent with a diameter of 11/2 ”, 2”. The frequency of rotation of the bending tool increased to 6 rpm, but along with this, the overall dimensions of 858x590x1115 increased. Electric drive power 3 kW. The STD-439 pipe bending machine was produced for about six years until 1989. In 1989, the STD-22012 pipe-bending machine was launched, which was manufactured in two versions: with a pyramidly located block of rollers for pipe bending by rolling in four sizes ½ ”, ¾”, 1 ”, 11/4” winding pipes 11/2 ", 2". The bed became welded. The pipe bending machine was equipped as well as the previous worm gear, but the gear wheel of the bending tool was already with internal gearing. Added mechanical brake. The rotational speed of the bending tool by the rolling-in method is 5 rpm, and the winding method is 2.5 rpm. The power of the electric drive increased to 4 kW. Overall dimensions increased and amounted to 925x690x1100. Machine weight reached 850 kg. The STD-22012 pipe bending machine was produced for a short time, only about three years before 1991. Starting from 1991, machines began to be developed by the design department of the Moscow Mechanical Plant. In 1991, an improved model of the STD-22012U pipe bending machine replaced the generation. For the bending of pipes, the extended run-in method was used for the first time due to interchangeable shoes and rollers. A wheel with internal gearing is installed on a welded frame with a worm gearbox and the carriage is first developed with the possibility of adjusting the center distance. From the previous machine remained the lower part, as well as the mechanical brake. The upper part has been improved, which made it possible to expand the range of flexible pipes from ½ ”to 2”. The rotational speed of the bending tool remained at 5 rpm with an electric drive power of 4 kW. Overall dimensions have changed in height due to the new upper part to 925x690x1000. The machine weight decreased to 780 kg. The pipe bending machine STD-22012 was produced for about three years until 1993. Along with the release of the pipe bending machine STD-22012U, since 1991 a series of machines UGS-1, UGS-2, UGS-3 as a whole has been experimental to produce optimal solutions. The machine also performed bending in an extended ½ ”to 2” range with a variable center distance. Welded bed, worm gear, without mechanical brake. A series of machines differed kinematics gears, gearboxes and electric motors. The rotational speed of the bending tool is 2 ... 4 rpm with an electric drive power of 3 ... 4 kW. Overall dimensions changed to 800x700x1000. The weight of the machine has noticeably decreased to 550 ... 650 kg. This experimental series of pipe bending machines was produced before 1995. In the same series in 1994 temporarily produced pipe milling machine UGS-4. The working table of the UGS-4 was a workbench, inside of which there was a drive for rotating a bending tool, which included a belt-driven motor, a worm gear of its own production, a screw pair with a gear rack, a preliminary gear and a main gear with external gearing. Made 2 prototype. When testing was revealed low efficiency worm and screw pair (own production). By increasing the power from 3 to 5.5 kW, the pipes ½ ”and ¾” were bent, then the frame twisting effect occurred. Due to the complexity of manufacturing a screw pair, a worm gearbox and a significant weighting of the frame on the UGS-4, it was decided in 1994 to launch the UGS-5 model with a fundamentally new layout and good efficiency into an experimental production machine. On the basis of proven technical solutions, starting with the STD 22012 UDF UGS-3 machine, the developed machine UGS-5 combined a large torque with optimum engine power with good efficiency and high performance due to the speed of the bending tool - 3 rpm. The machine was equipped with an octagonal bed with a planetary gearbox, a main gear with internal gearing and a carriage with a variable center distance allowed to make the machine versatile and multifunctional. The range of flexible pipes ½ ”, ¾”, 1 ”, 11/4”, 11/2 ”, 2 ". Significantly reduced dimensions to 720x700x900, as well as the weight of the machine for the first time was below 400 kg and amounted to 330 kg. The model turned out so successful that it even began to copy and forge competitors. Often, identical copies appeared on the market. Such a machine was produced for about 12 years until 2006, but time required modernization and improvements in the field of electronics and automation. In this regard, since 2007, a new sixth generation UGS-6/1 pipe bending machine has been launched into production. A distinctive feature of the machine was the transition to two modes of operation: automatic and manual. In the automatic mode, the bending process was first carried out by an electronic control system according to a given program. For steel pipe bending, the machine was equipped with sets in an extended range from 3/8 ”to 2”. The machine had a carriage with adjustable center distance. Torque created a progressive planetary gear, made according to the 3K scheme. The machine was equipped with a system of dynamic braking of the main drive. The frequency of rotation of the bending tool - 3.2 rpm with the power of the electric drive 3 kW. Overall dimensions 630x790x980. With the control panel, for the convenience located on the rotary bracket, the dimensions were 630x900x1140. The weight of the machine is 330 kg. The pipe bending machine UGS-6/1 was produced for about five years until 2012. Since 2012, an improved model of the sixth generation pipe bending machine, UGS-6 / 1A, has been launched. From the previous model, the machine was distinguished by a modern microprocessor control system for the angle of bending into which an encoder was first introduced. The control panel began to be located directly on the bed. For the convenience of the operator, the machine began to be supplied with a tray for laying the bending tool. Overall dimensions 630x780x1100. Machine weight dropped to 320 kg. Bending machines, since 1991, were developed by the Chief Designer of the Moscow Mechanical Plant No. 3 Malygin M.V. With each year, the tube bending machines are constantly being modernized and improved. Since 2015, UGS - 6 / 1A has become equipped with a modernized stationary control panel, and also provides the possibility of remote control using a radio channel. The upgraded electronics of the machine began to allow bending with high accuracy and stable repeatability of curved parts with minimal changes in the geometry of the profile without the formation of corrugations, breaks and other defects at a given angle of up to 180 degrees with an error of up to 0.5 degrees. Machine control is possible both in manual and automatic modes, and in automatic mode, the bending process is performed by an electronic control system, according to a given program. Modernized power control board providing higher reliability and stable operation in the power grid. The machine is equipped with a system of dynamic braking of the main drive. Due to the interchangeable tooling, it is possible to use the machine when performing various bending operations. The standard package includes six interchangeable pads and rollers designed for bending water and gas pipes in accordance with GOST 3262-75, with a diameter of ½ ”to 2” and a wall thickness of 2 to 4.5 mm. , square and rectangular rolled metal, strip, and also there is a possibility of bending reinforcement, which is important for the use of the machine on construction sites. More information about the capabilities of new machines can always be found by contacting the Moscow Mechanical Plant No. 3. Maintenance service of the UGS-6 / 1A pipe bending machineTo ensure reliable and durable operation of the UGS-6 / 1A, it is necessary to carry out maintenance of the machine, which consists of daily technical inspection and periodic maintenance.Daily technical inspection. During the daily technical inspection (ETO) the following work is performed: - external inspection of pipe bending machine units, if necessary, tighten fasteners; - check of good grounding and connection to the network, eliminate faults; - check the presence of lubricant on the driving screw and slideways of the central roller slide; if necessary, lubricate it according to the lubrication scheme. Upon completion of work on the pipe bending machine, you must: - clean the machine from scale and wipe; - lightly grease unpainted surfaces with oil И-20А. Periodic maintenance. Various variations of the pipe bending machineIt is extremely difficult to bend a pipe by hand even with the help of massive stationary devices, and there is no need to speak about bending accuracy. A long time ago, a manual pipe bender was invented, which is still used today, especially in private. But, unfortunately, not every pipe is subservient to it, and the pace of work is quite low. On an industrial scale requires something more solid, solid. Today, the industry has mastered a number of pipe bending machines of various modifications. This benders stationary and mobile type. This equipment is divided into units with manual hydraulic drive, machine tools with electric drive and universal models for spiral-ring bending of pipes. In the field of housing and communal services, as well as in industry, stationary pipe bending machines have become more common, while in construction a freighter of working sites is a mobile pipe bending machine. Usually the machine “mobile phone” is in demand where it was necessary to bend the pipe quickly, without being distracted from the main work. The electric pipe bender is designed for the treatment of rolled products which are distinguished by high strength, namely steel reinforcement bars and bars, a profile pipe and rolled products with a rectangular and circular cross section. The mentioned pipe bending machine allows you to cope with a large amount of material in a relatively short period of time. Representatives of this category of equipment are the UGS-5 pipe bender and the UGS-6 pipe bender, which bend the profile pipe at a given angle by running it around the shoe, while the material is not exposed to thermal effects. The use of pipe bending complexes in various types of production.Depending on the needs of the enterprise, in the working process special technological schemes and various types of tools are used, without which well-coordinated work of any production is not possible. The quality of the products obtained undoubtedly depends on three factors: the skill of the specialist, the quality of the source material and the specifics of the profile equipment. The latter includes pipe bending machines. The need for machine tools is constantly growing, as no specialist can manually achieve the same degree of performance. Modern pipe benders have a high level of accuracy, which is simply impossible to ensure without the use of special equipment. Sale of benders allows you to update the technical base and put the processing of rolled to a new level. Thus, knowing the main activity of the enterprise and its production load, it is possible to say with certainty which types of bending machines will be priority for each individual company. Pipe bending machine for construction companiesThe greatest need for equipment pipe bending experiencing modern construction companies. These enterprises, with their specific work, use a bending machine as peripheral equipment at almost every object. Depending on the complexity of the construction operations and the source material, the above-mentioned companies exploit almost the entire range of bending equipment. Such types of machine equipment, such as: manual pipe bender, and electric pipe bender, will be a great help at the base sites. With large production volumes and high strength of the rolled products, electric pipe benders are popular. An electric pipe bender, the price of which is an order of magnitude different from the price of hand-held machines, provides for the bending of a profile pipe, steel bars and bars, as well as rolled products of round or rectangular cross-section. The following models can be attributed to the number of high-quality equipment with electric supply: the UGS-5 pipe bender and the UGS-6 pipe bender. In addition to electric equipment, construction enterprises quite often use manual. The use of handheld equipment allows you to handle rental in hard-to-reach construction sites - where it is impossible to install a stationary complex. In addition, this pipe bending machine is light, compact and easy to carry. It is also important that the manual bending machine, the price of which ranges from $ 250 to $ 550, will pay off the enterprise in just a couple of months. While the quality of the products will be impeccable. It is flexible pipes on the metalworking enterprisesSome stages of the production of metal-working enterprises and factories cannot do without such type of equipment as a pipe bending machine. And if construction companies take into account mobility in the processing of rolled products, then large industrial enterprises rely on a high level of productivity. Pipe bending at metal-working enterprises is carried out with the help of stationary complexes on hydraulic systems or electric drives. It is noteworthy that the pipe bending machine with a hydraulic system at a price slightly lower than the equipment with an electric drive and a modern tooling system. On hydraulics it has a small weight and size, which makes it convenient for transportation and installation. Pipe bending machine(pipe bender) UGS-6/1 MMZ-3101- №1UGS-6/1 MMZ-3101-№1 is a modern technological equipment, allowing to carry out complex bending operations with various types of a profile. The pipe bender of this modification is designed for bending pipes made of stainless steel, ferrous and non-ferrous metals by running around the pads in a cold state. Pipe benders UGS-6/1 also perfectly cope with galvanized pipes and long products with the help of a special roller, which allows to automate the processing technology as much as possible. The machine MMZ-3101-№1 is a pipe bending equipment that functions in both manual and automatic modes. The uninterrupted operation of the machine is ensured by a special electronic control system that controls the UGS-6 pipe bender according to a predetermined program. Types of pipe bending complexesBased on the characteristics of rolled processing, production technology and control systems, pipe bending machines have the following classification: portable and stationary, hydraulic and mechanical systems, as well as electric and manual actuated pipe benders. Bending machine, the price of which varies depending on the complexity of the equipment, will be an excellent tool for a small enterprise for the primary processing of pipes, and for a large construction company. In addition, today there is a sale of pipe benders with an electronic device, which is intended for programming the coordinate system. It is necessary in case if it is required to be flexible water or gas pipes directly on the place of assembly. If the priority is high mobility and a small amount of pipe processing, then the manual pipe bender will be the best option in this case. With heavy loading and stationary use, it is best to use an electric bender. Greater capabilities and high power differs from conventional manual pipe benders hydraulic. The hydraulic system of this equipment allows you to process steel rolled with a diameter of up to 3 inches, while it does not require any additional effort on the part of a specialist. Pipe bending machine with hydraulics at a price significantly lower than equipment with electric drive and complex equipment. The hydraulic complex, as well as the manual pipe bending machine, is characterized by its small size and weight, thanks to which the machines can be transported for ease of installation. Pipe bending machine: advantagesThe process is labor-intensive, with a high level of accuracy, which allows to end up with high-quality products that have retained their technological characteristics and presentable appearance during processing. The bending machine UGS-6/1 MMZ-3101- №1 has a number of advantages:1. A convenient control system, which is equipped with bending machines, provides control over flexible pipes in two modes - automatic and manual. The electric pipe bender is equipped with an electronic control system, which allows a specialist to take minimal part in the process. 2. The bending of the profile pipe is carried out using a dynamic braking system. This system is reliable and convenient, since it can stop the main drive either by pressing the electric pedal or from the electronic control panel. 3. The pipe bending machine (UGS-5 pipe bender, UGS-6 pipe bender) has an additional configuration in the form of technological equipment, with the help of which bending operations are performed at different operating levels. 4. Taking into account all the technical characteristics, the above described equipment can be installed on an arbitrary solid foundation or coating, since it does not require a specially equipped platform. 5. The pipe bender, the price of which is acceptable even for a small business, fully justifies its cost with the high performance and quality of the products obtained. What are pipe bending machines and what you need to know when choosing a pipe bender.- this pipe benders , their performance allows you to minimize your costs and easily cope with mass production. The main scope of such a device as you can call the construction, service organizations performing repair work. It is in these situations that sometimes masters face the task of processing (bending) pipes or other metal profiles. Thanks to the use of such a device, you have an excellent opportunity to bend the pipe exactly as you need, while respecting all the necessary dimensions up to millimeters, and a special advantage is that you do not have to repair various creases or flattening of the material. Without pipe benders at the moment it is difficult to imagine any process of repair or construction, because very often there is a need for quick pipe bending on the place of installation. And the presence of various tooling for machines allows you to expand the possibilities in working with pipes of various diameters and sections. Pipe benders can be divided into several groups and categories: according to the principle of operation, stationary and manual ones can be distinguished, while according to the mechanism of action they are divided into mechanical and hydraulic. If you are faced with the task of bending or rounding off gas and water pipes, it is best to opt for portable ones with manual (used for a small amount of work) or an electric drive. So modern pipe benders will become your unique assistant in matters relating to the deformation (bending) of various types of pipes during construction work. Using a device called pipe bender, you will be able to handle rolled round, rectangular section. As a vivid example we can cite pipes, steel reinforcement, as well as all sorts of rods of various types of metal. At your will and necessity, you have the opportunity to adjust in advance the bending angle in pipe bender, there are also models in which this parameter can be programmed with the help of an electronic device, whose operation is based on reader-sensors. Availability of electronic devices in pipe benders allows you to easily make, for example, make 100 identical brackets, without using any templates and losing no time for readjustment. Another important parameter that needs to be guided in choosing can be called: diameter, pipe wall thickness, radius and bending angle of the workpiece. Accordingly, it is necessary to transfer the parameters of your pipe from the drawing to the machine that you want to purchase, analyzing the compliance of the pipe wall thickness and the bending internal radii that are possible - it is the optimality of these ratios that allows you to get the pipe (part) in a bent state without deformation. Whatever model of machine for pipe bending It was not always necessary to keep in mind the high degree of accuracy - here the engine braking system and the reliability of the installed electronic system play a big role. What else is worth paying attention to when choosing a model pipe bender? Let's give an example: if you use manual pipe benderOf course, it is convenient in terms of transportation, because it does not weigh too much. Benefits motor driven it is also evident: in this case, you get the opportunity to carry out a large diameter, among other things, similar models pipe benders also characterized by high performance. If you are faced with the task of working in small production workshops and you need to process copper and thin-walled pipes - manual pipe bender exactly what you need. If you have to install, or install all sorts of various communication networks - gas, water, heating, etc., be sure to use mobile manual pipe bender, since it is such models that will make it possible to bend pipes directly at the place of their installation. A few words about electric drive pipe benders: The main sphere of their application is the flexible pipes of large diameter. The advantages of these models must be attributed, and of course sufficient high performance. Using data pipe benders You can get the bending of the workpieces at an angle of up to 180º, and there will not be any pipe defects, such as corrugations or kinks. It should be noted that users prefer electromechanical pipe benders CNC, which are characterized by the possibility of programming multiple coordinates. Particular attention should be paid in this case to turning the bending head (carriage), turning the bending plane, as well as regulating the flow of the pipe. The advantages of electromechanical pipe benders It is necessary to relate with CNC first of all: high accuracy (up to 0.1 mm, 0.1 º), the lack is the high price and long payback period of the equipment. |

| Read: |

|---|

Popular:

New

- Appointment of planar marking

- What should be used reinforcing mesh for concrete, wallpaper, plaster technology - plastic, fiberglass or metal

- Edit strip and sheet material

- Open lesson "editing, bending"

- Installation of staircases and platforms: general information

- Repair of pipes of water supply in the apartment Repair of steel pipes

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

- What should be the sharpening angle of the scriber