Site sections

Editor's Choice:

- Why at home may there be a need for measuring water resistance?

- Alteration of "Khrushchev" dvushki almost treshku

- Paint the wallpaper with your own hands

- Installation options for drywall in the bathroom

- Court decision on recovery from the management company of the amount of damage to the gulf of the apartment

- Living room and children in the same room: options for partitions

- Top sofa upholstery rating: customer reviews

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

Advertising

| Scales by EscD Scales in drawing GOST. The scale of the drawings. Distance measurement by a caliper |

|

But it is not always possible to use a scale of 1: 1 due to the fact that the size and complexity of the products shown in the drawing are different; some products (for example, machine tools) are so large that their images at a scale of 1: 1 would require huge sheets of paper, drawing boards of appropriate size, rail cushions, etc .; implement all this is not possible. Some products (for example, clockwork mechanisms) are so small that it is almost impossible to carry out their images on a 1: 1 scale and, moreover, it is often impossible to understand the shape and dimensions of not only individual elements, but even entire parts from such an image. If there is a need for a greater reduction or increase in comparison with the above scales, you should apply: When the image details in an enlarged scale allowed to draw on the same sheet (in the upper left corner) its simplified image in full size. Above the image indicate a scale of 1: 1. The dimensions on this image are not indicated (see Drawing 640). If the scale fits into the column with the name assigned to it in the corner stamp, it is denoted 1: 1; 1: 2; 2: 1, etc. (Drawings 497 and 523), and in other cases M 1: 1; M 1: 2; M 2: 1, etc. (Drawing 640). Layout drawing.The layout of the drawing is the placement of images, sizes and inscriptions on the drawing field (ie, inside the frame). The layout of the drawing begins with the fact that they choose the format of the drawing in accordance with the overall (i.e., with the greatest in length and width) dimensions of the future image. For example, if the overall dimensions of an image are 218 X 170, then you need to select a format whose drawing field is slightly larger, for example, format 11; he has a drawing field equal to the size of the format minus the frame and stamp fields, i.e. With the correct layout of the drawing, the dimensional cell of the image should be equally spaced from the frame lines to the right and left; above the frame and below the stamp also at the same distance. If the image of the object is asymmetrical (it does not have symmetry axes, drawing 64, a), then according to the overall dimensions of the object, an overall cell is drawn inside the drawing field, spaced to the left of the frame at a distance b 2 = (b - b 1) / 2 and below the stamp on distance a 2 = (a - a 1) / 2 (drawing 64, b) and inside it draws an image of the object. This article highlights the main questions about how to how to make a drawing, the scale of the drawings, the design of the drawings, etc. The problem of drawing a drawing on their own, often, arises for students of elementary courses who study technology specialties or are educated in the field of artistic design or design. The rules that must be followed when creating drafting works are fixed in Gosstandart. They should know and adhere to anyone who receives education in these areas. However, the rules of the Gosstandart were issued for industrial use, therefore, in the drawings, sometimes, small deviations from the established norms are permissible. Forms of paper sheets and frames for themAny drawing is made on a sheet of paper, a standardized value, limited by a frame. Such a frame is applied by drawing a line of average thickness along the marking marked on the sheet. For drawings of different formats, certain sizes of the frames delineated in them are set:

Each smaller drawing is obtained by halving the values of the previous format. The main inscription of the drawingThe inscription on the drawing is located in the corner located to the right. It indicates:

When using A4 format, the main inscription is placed on the smallest side. If the format used is larger than A4, the label can be placed on either side. The source data for the drawing and work with himTo make the simplest drawing, you can either depict a detail that in the future will draw a drawing, on paper, in the form of a drawing in three projections, or have it before your eyes in the original. When depicting a detail in the form of a three-dimensional pattern, it is useful:

If the successive steps of the above algorithm were performed correctly, a copy of the original depicted on the paper will correspond to it. If, however, their similarity was not obtained, it will be necessary to make adjustments to the dimensional chains. A size chain is the cumulative size of a certain part of an image of an object that is applied to paper, which cannot be distorted up or down. Of course, depending on what goal you are pursuing when depicting the object in the figure, the accuracy of the dimensions may vary. For example, for domestic purposes, it happens to deviate within one to one and a half millimeters, and this is often acceptable. In technical drawing, dimensional chains are set taking into account various factors. What you need in order to "measure" the drawingThe correct creation of a drawing is not only in observing the external similarity of the image applied to a drawing paper or recreated in a computer program of an image with a real object. For technical purposes it is necessary that all image sizes match the original. In this regard, the concept of tolerance for accuracy was introduced. Tolerances in the dimensions that are indicated in the technical drawings are indicated taking into account the articulation of two adjacent parts with each other. A whole system of tolerances has been developed, taking into account how the parts interact with each other (moving or stationary interaction), as well as the nature of probable movements during their assembly or disassembly (often, rarely, always, never) and so on.

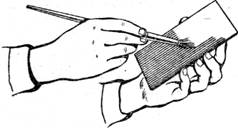

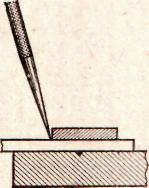

How to learn to read drawings?Drawings are 2-dimensional architectural schematic sketches that show the size of the building design. On the materials that will be used in construction. Learning to read blueprints is important for builders and any workers who hire architects to compile them. Training spatial imaginationStandard drawings usually have three projections of the object in which the axes of the coordinates X, Y, Z are located on the axis. However, with their composition, the scaling remains and for all is set the same. It is human nature to conduct observations of each object or part in geometrical isometry from a certain angle of view. This often happens in the fields of engineering drawing, and in the design development of objects of artistic and technical design. Therefore, it is worthwhile to present the drawing object as flat in a certain projection. And an additional detail is - the projection connection of different images of the object of the drawing. If all elements of both configurations are not built as it should with large-scale distortions, which will lead to a mismatch of the copy of the drawing with the originals. Therefore, it is necessary to observe a number of rules in the process of drawing up a projection: Measurements are carried out using a ruler - for simple ones, with a caliper or micrometer - for complex parts, for all dimensional elements. Set their relative position for each of the projections of the details. Match the results obtained with the actual image details. With bug fixes. Final measurements are taken of the distance on the original object or its layout of the drawing. If all the data are correct and match, then there were correctly read diagrams and drawings. How to measure?It does not matter what the scale of the drawings made, all attention is paid to the base of the part and its dimensions. When writing a certain number does not show the unit of measurement, which is standard. In order to designate the parameters of the part, a dimensional path is drawn with a number located on it. It is drawn parallel to the part of the part and is limited to arrows. The minimum distance between the dimension line and the part contour is 10 mm. How to get help in acquiring the skills of independent technical graphics? To master the skills of reading drawing tables, it is necessary to conduct a course of study and practical work. To carry out repairs simple design of household appliances, for the production of new and old element parts. It also has to make primitive drawings. Learn how to read the drawings correctly, and then learn how to present a flat picture in a drawing in volumetric form. Skills of reading drawings help to competently make all sorts of objects, collect them from the nodes, the final product, get the whole unit, models and much more. Types of formatsThe format of a sheet with a drawing is determined by the length of the line drawn on the edge of the sheet. Internal make up with distances of 2 cm from the left side and 5 mm from the others. It is necessary to adhere to the exact calculations of the drawing, so that when reading them there would be no disagreement about how the part looks. Drawing frame formats are divided into main and additional directions. The first type includes all the schemes obtained by reducing the lines by half from the point A0. Dimensions for the drawing A1, carried out so that when the largest axis of them is divided into two, a rectangle similar to the original sample is obtained. The designation of standard formats consist of a letter and a number from one to five. Automatic drawingThe first place was taken by those drawings that are made using computer-aided design programs. For different designs and parts. This applies to two systems - Auto - cad and Compass. They read the drawings of a different type. And set the image of the entire site. And after made the design of parts included in the assembly unit. Thanks to their work with whole libraries of source data. After all, they include specialized normalized and standardized elements. Using it in the work, the developer is able to insert a fragment into the workpiece, controlling individual parameters, and adapting the drawing for new source data.

Scale of drawingsNecessary requirements and features. To begin with, the scale is the ratio of the linear dimensions of an image plotted on a drawing or map to its actual size on a terrain or object. Its application greatly facilitates the mapping of maps and drawings, because it is not always convenient and possible to depict an object in its full size. There are parts with large sizes that do not allow them to be drawn on paper, and it happens that a part is very small and, in order to display it on paper with all the nuances, it is necessary to significantly increase its size. In the cases presented, a decrease and an increase in scale are used. Standard scalesA few common reduction scales:

For example, the scaling option is 1: 4. The number that stands first — the unit — denotes the actual dimensional characteristics of the item, while the second number, in this case, the four, indicates how many times these actual dimensions have been reduced. When depicting a very small object, the zoom is applied, and this is indicated as follows: 2: 1; 2.5: 1; 50: 1. With this option, to find out the actual dimensions of the object, it is necessary to divide the dimensions indicated in the drawing by the first number reflected in the scale. How to determine the scale?In order to depict an object or part on a piece of paper, first of all, you need to find out its true dimensions. This can be done by removing measurements from the item depicted in the drawing with a ruler, and only then we can figure out how much to reduce or increase its actual dimensions when applying its image on a sheet of paper. Drawings, for the most part, are used in construction and in the development of parts and structures. The use of scaling allows designers and designers to depict a huge building and a reduced exact copy of the aircraft on a sheet of paper. How to choose the right and, most importantly, the right scale when working with drawings? Most inexperienced people, faced with such a question, as a rule, make quite a few mistakes. However, this can be avoided due to the experience gained over time, or you can seek help from a teacher. Why is it necessary to follow the rules?When drafting drawings and schemes, it is necessary to follow certain standards reflected in the GOST - a document that contains generally accepted rules for applying images, inscriptions, tables and technical requirements. With the help of these rules, any workman who is able to read the drawings will be able to read the correct drawing work. This greatly facilitates communication, in the construction and production of parts, designers with workers who perform tasks on the drawing. In addition to scale, the drawing is applied and other information relating to the subject. You should know the basic rules for drawing up drawings and diagrams:

If you use all the above rules, you can create a really high-quality drawing work that any specialist will be able to read.

Design drawingsThe process of preparing any work required for certification in construction, design and architectural specialties studied in higher educational institutions, involves the production of drawings. Making a drawing is not an easy task. Its creation is required to take into account the observance of certain rules. In addition, any drawing work must be framed on sheets of a certain size. The nuances of using different formatsThe format of the drawing is limited to the scope of the work done, which are applied to the sheet with a minimum thickness line. The completed work allows students to take into account the size of all formats used in the work. By dividing the work into two parts, a drawing is drawn up containing the following characteristics:

For other formats of drawings, the rules also set the dimensions of their sides:

Also, according to GOST, the possibility of using other formats used as an addition to the drawings made by students, which are formed as a result of work on changing the basic parameters upwards, should be taken into account. At the same time, to create them, a multiple of the sizes used in the basic formats is applied, and the coefficient of the changes made must necessarily be an integer. Machines and some of their parts, buildings and their parts are large, so draw them in full size is not possible. Their images have to be drawn into. The smallest details of wrist watches and other mechanisms have to be drawn, on the contrary, on the scale of magnification. In all cases, when possible, the details should be drawn in full size, i.e. in a scale of 1: 1. Reducing or enlarging images in an arbitrary number of times is not allowed. GOST 2.302-68 set the following reduction scales: 1: 2; 1: 2.5; 1: 4; 1: 5; 1:10; 1:15; 1:20; 1:25; 1:40; 1:50; 1:75; 1: 100; 1: 200; 1: 400; 1: 500; 1: 800; 1: 1000. When drawing up master plans for large objects, it is allowed to use scales of 1: 2000; 1: 5000; 1:10 000; 1:20 000; 1:25 000; 1:50 000. Zoom scales are recorded as a ratio to one; The standard establishes the following magnification scale: 2: 1; 2.5: 1; 4: 1; 5: 1; 10: 1; 20: 1; 40: 1, 50: 1; 100: 1. In necessary cases it is allowed to apply magnification scales (100l): 1, where n is an integer. In cases where the full word “scale” is not in the record, before the designation of the scale they put down the letter M, for example, they write: M 1: 2 (scale reduction), M 2: 1 (scale zoom). In fig. 1 rectangular washer is depicted on three scales: full-size (M 1: 1), scaled down and scaled up. The linear dimensions of the last image are four times larger than the average, and the area occupied by the image is sixteen times larger. Such a dramatic change in image size should be considered when choosing the scale of the drawing. TBegin -\u003e TEnd -\u003e Fig. 1. Comparison of different scales. Linear scales In addition to numerical scales, linear scales are used in drawing. Linear scales There are two types: simple and transverse (Fig. 1). A simple linear scale corresponding to a numerical scale of 1: 100 is a line on which centimeter divisions are placed from the zero division to the right, and the same division divided by millimeters to the left. Each centimeter division of the linear scale corresponds to 100 cm (or 1 m). Each millimeter division obviously corresponds to one decimeter. Taking a gauge of any size from the drawing, put one needle on the corresponding complete division to the right of zero, The advantages of a simple linear scale over a conventional ruler are as follows:

More perfect is linear cross scale. In the drawing it is given for the same scale of 1: 100. Oblique lines, transversals, allow you to get not only decimeters, but also centimeters. For example, the scale shows a size of 3.48 m. Linear scales are used mainly in construction and topographic drawings. TBegin -\u003e Fig. 2. Scale graph In the design and production practice is often used proportional (angular) scale. It is the simplest graph. Suppose you want to build such a graph for a scale of 1: 5. On the horizontal line from point A (Fig. 2) lay a segment equal to 100 mm; at point B, a right angle is built and a segment reduced by 5 times (100: 5 = 20 mm) is laid on its second side; connect the obtained point C with point A. The value of 12.8 mm, corresponding to 66 mm, is taken by a caliper directly from the graph, without calculating it and without using a ruler. The graph is built on graph paper or on a graphene paper. For a scale of 1: 2.5, the extension of the leg of the sun is laid off 40 mm; for a scale of 1: 2-50 mm. The row of proportional scales shown in the figure is called the scale chart. Using them allows you to save a significant amount of time. Having built a graph of scales, they use it throughout the course of work on the course of drawing. Before you begin to consider the standard scale of the drawings, you should understand exactly what this concept represents. So, such a value is in the general case a ratio of two linear dimensions. However, this interpretation of this definition, as the ratio of the size of a drawing to the dimensions of a real object, is more widely known. Therefore, it is quite possible to assume that the above term has found wide application in cartography, geodesy and, of course, design. Why is this necessary?As mentioned earlier, real objects can be both quite significant and very small. However, a person cannot draw everything in full size, since a canvas of colossal dimensions would be needed to display on a sheet of paper, and, in turn, to recreate small elements (such as in a clockwork) would require a high degree of detail. As a result, the person has adapted to depict the necessary objects, which are reduced (or increased) a certain number of times for ease of perception and the so-called "readability" of the drawing. Currently, there are certain standards, for example, GOST “Scale of Drawings”, which describe all the requirements for the type and content of the relevant images.

Large objectsAs mentioned earlier, to display buildings and other large items, it is necessary to use the scale of the drawings of the so-called reduction. They are standardized, which means that random sampling will not work. The most common values are: 1: 2; 2.5; four; five; ten; 15; 20; 25; 40; 50; 75; 100; 200; 400; 500; 800; 1000. Consider what a recording of this kind means. So, the real (in other words, natural) envelope of an object is expressed as 1: 1. Consequently, when reducing the scale of the drawings, first describe the original size (1), and then a number that shows how many times the drawing is reduced relative to to real dimensions. In construction, in addition to the above standard entries, the indicators 1: 2000 can also be used; 5000; 10,000; 20,000; 25,000; 50,000. Small parts

In the event that it is necessary to depict small objects in the figure, then the scale of magnification drawings is traditionally used. In this case, there is no such wide variety of values, however, the standard specifies the most frequently used values. So, the type series is as follows: 2; 2.5; four; five; ten; 20; 40; 50; 100: 1. The decoding of such inscriptions reads like this: first, the number indicating how many times the image in the drawing is enlarged compared to the original object. The second digit, after a colon, displays the real (or natural or real) size of the object under consideration (assumed to be 1). ConclusionThis article examined the scale of the drawings and their standard series. It should also be noted that on the plans, projects and images themselves, the scale value is indicated in a specially designated column in a frame, otherwise called a stamp. Machines and some of their parts, buildings and their parts are large, so draw them in full size is not possible. Their images have to be drawn into. The smallest details of wrist watches and other mechanisms have to be drawn, on the contrary, on the scale of magnification. In all cases, when possible, the details should be drawn in full size, i.e. in a scale of 1: 1. Reducing or enlarging images in an arbitrary number of times is not allowed. GOST 2.302-68 set the following reduction scales: 1: 2; 1: 2.5; 1: 4; 1: 5; 1:10; 1:15; 1:20; 1:25; 1:40; 1:50; 1:75; 1: 100; 1: 200; 1: 400; 1: 500; 1: 800; 1: 1000. When drawing up master plans for large objects, it is allowed to use scales of 1: 2000; 1: 5000; 1:10 000; 1:20 000; 1:25 000; 1:50 000. Zoom scales are recorded as a ratio to one; The standard establishes the following magnification scale: 2: 1; 2.5: 1; 4: 1; 5: 1; 10: 1; 20: 1; 40: 1, 50: 1; 100: 1. In necessary cases it is allowed to apply magnification scales (100l): 1, where n is an integer. In cases where the full word “scale” is not in the record, before the designation of the scale they put down the letter M, for example, they write: M 1: 2 (scale reduction), M 2: 1 (scale zoom). In fig. 1 rectangular washer is depicted on three scales: full-size (M 1: 1), scaled down and scaled up. The linear dimensions of the last image are four times larger than the average, and the area occupied by the image is sixteen times larger. Such a dramatic change in image size should be considered when choosing the scale of the drawing. TBegin -\u003e TEnd -\u003e Fig. 1. Comparison of different scales. Linear scales In addition to numerical scales, linear scales are used in drawing. Linear scales There are two types: simple and transverse (Fig. 1). A simple linear scale corresponding to a numerical scale of 1: 100 is a line on which centimeter divisions are placed from the zero division to the right, and the same division divided by millimeters to the left. Each centimeter division of the linear scale corresponds to 100 cm (or 1 m). Each millimeter division obviously corresponds to one decimeter. Taking a gauge of any size from the drawing, put one needle on the corresponding complete division to the right of zero, The advantages of a simple linear scale over a conventional ruler are as follows:

More perfect is linear cross scale. In the drawing it is given for the same scale of 1: 100. Oblique lines, transversals, allow you to get not only decimeters, but also centimeters. For example, the scale shows a size of 3.48 m. Linear scales are used mainly in construction and topographic drawings. Fig. 2. Scale graph In the design and production practice is often used proportional (angular) scale. It is the simplest graph. Suppose you want to build such a graph for a scale of 1: 5. On the horizontal line from point A (Fig. 2) lay a segment equal to 100 mm; at point B, a right angle is built and a segment reduced by 5 times (100: 5 = 20 mm) is laid on its second side; connect the obtained point C with point A. The value of 12.8 mm, corresponding to 66 mm, is taken by a caliper directly from the graph, without calculating it and without using a ruler. The graph is built on graph paper or on a graphene paper. For a scale of 1: 2.5, the extension of the leg of the sun is laid off 40 mm; for a scale of 1: 2-50 mm. The row of proportional scales shown in the figure is called the scale chart. Using them allows you to save a significant amount of time. Having built a graph of scales, they use it throughout the course of work on the course of drawing. INTERSTATE STANDARD UNIFORM SYSTEM DESIGN DOCUMENTATION SCALE Moscow INTERSTATE STANDARD 1. This standard establishes the scale of images and their designation on the drawings of all industries and construction. The standard does not apply to drawings obtained by photographing, as well as to illustrations in print publications, etc. (Modified edition, Changes No. 1, No. 2). 2a In this standard, the following terms are used with the corresponding definitions: scale: The ratio of the linear size of the segment in the drawing to the corresponding linear size of the same segment in nature; actual size scale: Scale with a 1: 1 ratio; zoom scale:Scale with a ratio greater than 1: 1 (2: 1, etc.); zoom out: Scale with a ratio less than 1: 1 (1: 2, etc.). (Entered additionally, Amendment No. 2). 2. The scale of the images in the drawings should be selected from the following row:

3. When designing master plans for large objects, it is allowed to use scales of 1: 2000; 1: 5000; 1: 10,000; 1: 20,000; 1: 25,000; 1: 50,000. 4. In necessary cases it is allowed to apply scales of increase (100 n): 1, where p - integer. 5. The scale indicated in the designated main inscription of the drawing shall be designated as 1: 1; 1: 2; 2: 1, etc. The scale of the drawing is the ratio of its linear dimensions to the actual size of the depicted object. This makes it possible to judge the parameters of the object in question. Using natural dimensions in the preparation of the drawing is not always possible. There are several reasons for this:

In such cases, the images are drawn reduced or enlarged. Standard scalesScale reduction include:

The first number indicates that the scale of the image is two times smaller than the size of the object. In the case when the part or mechanism is small, other designations are used: 2: 1, 2.5: 1, 5: 1, 10: 1. Also, an increase is made 20, 40, 50 and 100 times. How to determine the scaleTo correctly determine the scale of the drawings in accordance with GOST, it is necessary to know the parameters of the part or mechanism. If the object is large, then it can be reduced by dividing by the numbers presented. An example is a double resize. If a part reduced by half will fit on a sheet of paper for a drawing, then the scale is 1: 2. Any item that needs to be depicted can be measured by standard methods (using a ruler, for example), in order to transfer them to paper. The same thing happens when creating something based on a drawing. According to the specified scale, the exact dimensions are determined. Mainly drawings are used:

Resizing allows you to work on designing an object on a small paper surface, which simplifies the process. If the scale of a certain section of the drawing is different (as happens during construction), then a designation with the required number is put near it. When creating drawings, many students make mistakes due to lack of experience and knowledge. To avoid this, it is enough to order the services of our company. Experts will quickly complete the work, which will allow you to get a good grade and see an example of a high-quality drawing. In addition, we can order the implementation of a term paper, a thesis or an essay that will be done strictly within the stipulated time frame. Why it is necessary to follow GOSTThe document regulating the application of inscriptions, tables, as well as technical requirements, highlights the rules by which the drawing up of each drawing takes place according to certain standards. This contributes to the creation of graphic information that is understandable for any engineer or builder who uses it in their professional activities. Careful reading of the documents will allow for the correct presentation of the information and the scale of the drawings. GOST 2.302-68 * contains the following rules:

Compliance with all these rules will allow you to create a drawing that meets all the requirements and therefore will be convenient for use. This is the ratio between the natural dimensions of the object or object to the linear dimensions shown in the drawing. The scale of the drawings can be expressed as a number, in which case they are called numerical scales and graphically linear scales. The numerical scale is indicated by fraction and shows the multiplicity of reduction as well as the increase in the size of the depicted objects in the drawing. Depending on the purpose of the drawings as well as on the complexity of the shapes of the depicted objects and structures in the drawing, the following are used in the preparation of drawing documents: Reductions 1:2; 1:2.5; 1:4; 1: 10; 1:15; 1:20; 1:25; 1: 40; 1:50; 1:75; 1: 100; 1:200; 1:400; 1:500; 1:800; 1:1000; Increases:2:1; 2.5:1;4:1; 5:1; 10:1; 20:1; 40:1; 50:1; 100:1;

If the drawing is carried out in one scale, then indicate its value in the column of the main inscription of the drawing as 1: 1; 1: 2; 1: 100, and so on. If any image in the drawing is made to a scale that differs from the specified scale in the main inscription of the drawing, then the scale type M 1: 1; M1: 2 and so on under the appropriate image name. When drawing construction drawings and using a numerical scale, it is necessary to make calculations to determine the size of the line segments that are plotted on the drawing. For example, if the length of the depicted object is 4000 millimeters, and the numerical scale is 1:50, in order to calculate the length of the segment, it is necessary to divide 4000 millimeters by (reduction rate) 50, and put the resulting value of 80 millimeters on the drawing. In order to reduce the calculations, a scale bar is used or a linear scale is built (see Figure 4a) on a 1:50 numerical scale. A straight line is drawn at the beginning of the drawing and the base of the scale is laid several times on it. The base of the scale is the value which is obtained by dividing the unit of measurement adopted in this case (1 m = 1000 mm.) By the size of a decrease of 1000: 50 = 20 millimeters. On the left side, the first segment is divided into several equal parts, so that each division corresponds to an integer. If you divide this segment into ten equal parts, then each division will correspond to 0.1 meter, if you divide it into five parts, then 0.2 meter. In order to use the linear scale built, for example, to take a size of 4,650 millimeters, it is necessary to put one leg of the measuring caliper four meters, and the other to put the fractional division on the sixth and a half to the left of zero. In the case when the accuracy is insufficient, use a transverse scale. Scale drawings — transverse and angular (proportional)The transverse scale allows you to determine the size with a certain error. The error can be up to hundredths of the main unit of measurement. Figure 4b shows an example of determining the size equal to 4.65 m. Hundredths take on the vertical segment and the tenths on the horizontal segment. In the case when an arbitrary scale is used and it is necessary to construct a reduced or enlarged image of an object performed according to a given drawing format, an angular scale is used or as it is also called proportional. The angular scale can be built in the form of a right triangle. The ratio of the legs of such a right triangle is equal to the magnification ratio of the image (h: H). If you need to change the image scale using the angular scale, using only abstract values and do not calculate the size of the depicted object. For example, when it is necessary to draw a given drawing on an enlarged scale. We build for this a right triangle (see Figure 4c) ABC. Such a triangle has a vertical sunburst equal to a segment of some kind of straight line, which is taken on a given drawing. The horizontal leg AB is equal to the length of the segment in the scale of the enlarged drawing. In order to increase the desired segment of a straight line on a given drawing, for example, segment h, it is necessary to postpone it parallel to the leg of the sun of the angular scale (vertically), between the hypotenuse of the AU and the leg of the AV. In this case, the increased size of the desired segment will be equal to the size H, taken (horizontally) on the side AB of the angular scale. The angular scale is also used to convert values from one numerical scale to another. The scale is the ratio of the linear dimensions of the image in the drawing to its actual size. The scale of the images and their designation on the drawings sets GOST 2.302-68 (table 5.3). The scale indicated in the designated main inscription of the drawing should be designated as 1: 1; 1: 2; 1: 4; 2: 1; 5: 1; etc. Table 5.3 - Scale Drawings When designing master plans for large objects, it is allowed to use scales of 1: 2000; 1: 5000; 1: 10,000; 1: 20,000; 1: 25,000; 1: 50,000. 5.3 Main title.Each sheet is framed, the line of which is separated from the three sides of the format by 5 mm from the left side by 20 mm. On the frame line in the lower right corner of the format have the main inscription in accordance with GOST 2.104-68. On A4 sheets, the main inscription is placed only along the short side. The type and thickness of lines in drawings, diagrams and graphs must comply with GOST 2.303-68. Drawings of the design documentation of the project are performed with a pencil. Schemes, graphs, tables are allowed to perform black ink (paste). All inscriptions in the drawing field, dimensional numbers, filling in the main inscription shall be made only in drawing font according to GOST 2.304-81. Thematic titles on the sheets do not depict, since the name of the contents of the sheet is indicated in the title block. In cases where the sheet with one inscription contains several independent images (poster material), separate images or parts of the text are provided with headings. The main inscription on the first sheets of drawings and diagrams must comply with form 1, in text design documents - form 2 and form 2a on subsequent sheets. It is allowed to apply form 2a on subsequent sheets of drawings and diagrams. The angular inscription for drawings and diagrams is located in accordance with Figure 5.1. Filled with turning the sheet 180 o or 90 o. Figure 5.1 – Layout of the main inscription on various drawings In the columns of the main inscription, figures 5.2, 5.3, 5.4, indicate: - in column 1 - the name of the product or its component: the name of the schedule or scheme, as well as the name of the document, if a cipher is assigned to this document. The name should be short and recorded in the nominative singular. If it consists of several words, then a noun is put in the first place, for example: “Threshing drum”, “Safety clutch”, etc. It is allowed to record in this column the name of the contents of the sheet in the manner adopted in the technical literature, for example: “Economic indicators”, “Process map”, etc .; - in column 2 - the designation of the document (drawing, graphics, diagrams, specifications, etc.); - in column 3 - the designation of the material (the column is filled only on the drawings of parts). The designation includes the name, brand and standard or technical conditions of the material. If the material stamp contains its abbreviated name “St”, “MF”, then the name of this material is not indicated. Figure 5.2 - Form No. 1 Figure 5.3 - Form No. 2 Figure 5.4 - Form number 2a Examples of recording material: - СЧ 25 GOST 1412-85 (gray cast iron, 250 - ultimate tensile strength in MPa); - KCh 30-6 GOST 1215-79 (ductile iron, 300 is the ultimate tensile strength in MPa, 6 is the relative elongation in%); - HF 60 GOST 7293-85 (high-strength cast iron, 600 is the tensile strength in MPa); - St 3 GOST 380-94 (carbon steel of ordinary quality, 3-serial number of steel); - Steel 20 GOST 1050-88 (carbon steel, structural quality, 20- carbon content in hundredths of a percent); - Steel 30 KNZA GOST 4543-71 (alloyed structural steel, 30- carbon content in hundredths of a percent, chromium is not more than 1.5%, nickel is 3%, A is high-quality); - Steel U8G GOST 1425-90 (tool carbon steel, 8 - carbon content in tenths of a percent; G - high content of manganese); - Br04TS4S17 GOST 613-79 (bronze is deformable, O- tin 4%, Z-zinc 4%, C-lead 17%); - BrА9Mts2 GOST 18175-78 (tinless bronze - LTs38Mts2S2 GOST 17711-93 (cast brass, zinc 38%, manganese 2%, lead 2%); - AL2 GOST 1583-89 (aluminum casting alloy, 2-serial number of the alloy); - AK4M2TS6 GOST 1583-93 (aluminum alloy casting, silicon 4%, copper 2%, zinc 6%); - AMts GOST 4784-74 (aluminum alloy deformable, manganese 1.0 ... 1.6%). In the manufacture of parts from the range: - Square

- Hexagon

- Strip

- Corner

- I-beam

- Pipe 20x2.8 GOST 3262-75 (non-galvanized ordinary pipe of conventional manufacturing accuracy, unmeasured length, with a conditional passage of 20 mm, wall thickness of 2.8 mm, without thread and without coupling); - Pipe Ts-R-20x2.8 - 6000 GOST 3262-75 (pipe with a zinc coating of increased manufacturing accuracy, measuring length 6000 mm, with a conditional passage of 20 mm, with thread);

- Column 4 - the letter assigned to this document according to GOST 2.103-68, depending on the nature of the work in the form of a project. The graph is filled from the left cell: –Y - training document; –DPP - diploma project documentation; –DR - thesis documentation; –KP - course project documentation; –KR - coursework documentation; - Column 5 - product mass (in kg) according to GOST 2.110-95; on the drawings of parts and assembly drawings indicate the theoretical or actual weight of the product (in kg) without indicating the units of measure. It is allowed to specify the mass in other units of measurement, indicating them, for example, 0.25 g, 15 tons. In drawings made on several sheets, the mass is indicated only on the first one. On the dimensional and installation drawings, as well as on the drawings of parts of prototypes and individual production it is allowed not to specify the mass; - Column 6 - scale (supplied in accordance with GOST 2.302-68). If the assembly drawing is carried out on two or more sheets and the images on separate sheets are made on a scale different from that indicated in the main inscription of the first sheet, column 6 of the main inscription on these sheets is not filled out; - Column 7 - the serial number of the sheet (on documents consisting of one sheet, the column is not filled). Column 8 - the total number of sheets of the document (the column is filled only on the first sheet). Column 9 - the name or the distinguishing index of the enterprise issuing the document (since the department on which the graduation project is carried out is ciphered in column 2 - the designation of the document, in this column it is necessary to put down the name of the institute and group code). For example: “PGSHA gr. To-51 "; - Column 10 - the nature of the work performed by the person signing the document. In the thesis project graph is filled, starting from the top line with the following abbreviations: - "Developed"; - "Consult"; - “Hands. etc."; - “Head. Kaf. " - "N. kontr.". - Column 11 - the name of the persons who signed the document; - Column 12 - the signatures of persons whose names are indicated in column 2. Signatures of the persons who developed this document and those responsible for the standard control are mandatory; - Column 13 - the date of signing the document; |

Popular:

New

- How to rivet a rivet - automatic and manual methods for different materials What rivet rivet steel sheets

- Appointment of planar marking

- What should be used reinforcing mesh for concrete, wallpaper, plaster technology - plastic, fiberglass or metal

- Edit strip and sheet material

- Open lesson "editing, bending"

- Installation of staircases and platforms: general information

- Repair of pipes of water supply in the apartment Repair of steel pipes

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

TEnd -\u003e

TEnd -\u003e

Full-size image 1: 1. In the process of designing master plans of large objects use the following scales: 1:2000; 1: 5000; 1:10000; 1:20000; 1: 25000; 1:50000

.

Full-size image 1: 1. In the process of designing master plans of large objects use the following scales: 1:2000; 1: 5000; 1:10000; 1:20000; 1: 25000; 1:50000

. pressure treated, A-aluminum 9%, manganese 2%);

pressure treated, A-aluminum 9%, manganese 2%); (from a bar of a square profile with a side size of 40 mm square according to GOST 2591-88, steel grade 20 according to GOST 1050-88);

(from a bar of a square profile with a side size of 40 mm square according to GOST 2591-88, steel grade 20 according to GOST 1050-88);

(hot-rolled round steel of usual rolling accuracy in diameter of 20 mm according to GOST 2590-88, steel grade St 3 according to GOST 380-94, supplied as per technical requirements of GOST 535-88);

(hot-rolled round steel of usual rolling accuracy in diameter of 20 mm according to GOST 2590-88, steel grade St 3 according to GOST 380-94, supplied as per technical requirements of GOST 535-88);

(angular ravnopolochnaya steel size 50x3 mm according to GOST 8509-86, steel grade St 3 according to GOST 380-94, the usual rolling accuracy B, supplied to the technical requirements of GOST 535-88);

(angular ravnopolochnaya steel size 50x3 mm according to GOST 8509-86, steel grade St 3 according to GOST 380-94, the usual rolling accuracy B, supplied to the technical requirements of GOST 535-88); (I-beam hot-rolled number 30 according to GOST 8239-89 of increased accuracy (B), steel grade St 5 according to GOST 380-94, supplied to the technical requirements of GOST 535-88);

(I-beam hot-rolled number 30 according to GOST 8239-89 of increased accuracy (B), steel grade St 5 according to GOST 380-94, supplied to the technical requirements of GOST 535-88); (seamless steel pipe of standard manufacturing accuracy according to GOST 8732-78, with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a multiple of 1250 mm, steel grade 10, manufactured according to group B of GOST 8731-87);

(seamless steel pipe of standard manufacturing accuracy according to GOST 8732-78, with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a multiple of 1250 mm, steel grade 10, manufactured according to group B of GOST 8731-87); (seamless steel pipe according to GOST 8732-78 with an inner diameter of 70 mm, wall thickness 16 mm, unmeasured length, steel of grade 20, category 1, manufactured in group A, GOST 8731-87);

(seamless steel pipe according to GOST 8732-78 with an inner diameter of 70 mm, wall thickness 16 mm, unmeasured length, steel of grade 20, category 1, manufactured in group A, GOST 8731-87);