Site sections

Editor's Choice:

- Why at home may there be a need for measuring water resistance?

- Alteration of "Khrushchev" dvushki almost treshku

- Paint the wallpaper with your own hands

- Installation options for drywall in the bathroom

- Court decision on recovery from the management company of the amount of damage to the gulf of the apartment

- Living room and children in the same room: options for partitions

- Top sofa upholstery rating: customer reviews

- Expansion joints in buildings

- Chaber - what is it and its purpose

- Sharpening wood cutters: manual work, using grinding wheels and a grinding machine

Advertising

| Making rust on the facade of the house of plaster. Greetings from ancient Rome - rusticated facades. Creating thin rust with a saw |

|

Rusta - one of the main types of architectural design of socles and walls of facades. The seams between the stones (tapes) are made horizontal and vertical, of various shapes, widths and depths. Most often rusta stuffed (Fig. 100) with steel rulers, cut with a saw, make out using supplementary smooth wooden slats. Difficult rusts draw patterns. Before stuffing rustov surface of the wall or base mark on the stones with a chop cord or ruler. A steel ruler (Fig. 100, a) is filled with rust by a fresh, non-adhered layer of plaster. Line sizes: thickness 8-10, width 40-50, length 500-800 mm. To obtain rectangular seams, the ruler is applied with an edge to the marking line and with a light tapping of the hammer it is deepened by 5-10 mm, after which the ruler is carefully removed. Thin rusta cut with a saw on the strengthened plaster. A rule is made on the breakdown and a saw trimming 20-30 cm in size, clamped in a cage, rusts are sawed through (fig. 100, b). To obtain a wider rustling (1-2 cm), it is cut through a non-reinforced plaster with a rustic sheet along the attached ruler. With the help of battens, Rusta is satisfied as follows. The planed wooden slats of trapezoidal section are attached to the broken surface of the walls or the basement; the gap between them is filled with mortar, leveling and compacting it. Depending on the required depth of the rust, the slats are installed in the ground or in the covering layer. After setting the solution, the slats are taken out and straighten the damaged areas and edges. The shape and size of the rails depends on the shape and size of the rust. By a pattern (Fig. 100, c, d), the rusts are pulled out according to the established lath-rules, similar to the drawing out of ordinary rods. Depending on the relief and depth, the rusts are pulled out in the depths of the soil or on the covering layer. The template is prepared for the simultaneous thrust of one tape or two tapes of rust along with the stone plane enclosed between them. The body of deep rustov form the projections of the brickwork. Prior to performing works on rusting on the ceilings, the seams between the plates are caulked so that it is recessed into the seam 15-20 mm from the front surface of the plates, then the seam is filled with mortar and leveled with a trowel flush with the ceiling surface. After the mortar has partially set, rusts are cut with the help of special rusting tools, which are attached to the installed guide rail on the ceiling and when pressed slightly pressed against it. Guide rails are attached to the ceiling with two or three thin mounting rails, which are 10-15 cm larger than the height of the room. Reiki placed between the guide rail and the floor, for which they are slightly bent. Curved slats firmly clamp the slats to the ceiling. Instead of rails it is recommended to use telescopic racks. The facade with rustami looks more aesthetically pleasing and attractive. These decorative elements give the structure a finished look, besides, they contribute to better heat and sound insulation of the house. Ways to create rust on the facadeThe easiest option is to use. Plaster rusts are made by cutting out the dried solution or packing special tools for raw plaster. Another option - Rusta for the facade of the house of polyurethane or foam. This method is the easiest, since it involves the use of ready-made elements. They are mounted on the facade with the help of liquid nails, while the installation does not take much time and effort. Rusty can be not only at the corners of the house, but also on the entire area of its walls. To obtain such an effect, rusticated wooden slats are used. The wall is pre-marked, then the slats are attached to it and a solution is applied. When the solution dries and sets, the slats take out and align the edges and edges of the “stones”, and also process their surface for the necessary texture. In addition, you can apply the method of extrusion of plaster, when on the primer make the markup and fix the template, and at the time of application of the finishing layer is gradually removed. Usually, horizontal stripes are made first, and then vertical. The benefits of finishing the facade rustamiThe so-called rusty stones are perfectly suited to lovers of the classics, solidity and geometric correctness of forms. They create a unique view of the structure, dramatically changing the overall perception. Light rusts on a dark brick facade look especially good. It turns out a contrast and very expressive. In addition to the purely decorative function, rusta often play the role of insulant. This fully applies to polystyrene decorative products.

In the classical architectural design of the facades of buildings, there is such a thing as rustic - sections of a wall or a wall entirely, the finish of which is presented in the form of piece cladding products with a clearly visible seam. It is this seam, which separates piece goods one from another along its square or rectangular perimeter, which is called rust. It is important to know that the rust can be performed in different bends, that is, forms in its cross-section, but at the same time remain strictly straightforward. This decoration technique was used to impart a feeling of heaviness and monumentality of the building and was carried out using purely stone piece materials. However, such materials are expensive, and laying them is not easy, therefore, imitation is often performed, which is a rustic plaster. Previously, the process of producing such a “wet” finish took a lot of time, but today the rusticated finish is carried out mainly according to modern technologies and materials, which makes the process much easier. Actually, we will talk about how to implement it using modern and traditional technologies, as well as its variations.

The shape of the rust, as well as its depth, regulate the appearance, betraying or repulsing the massiveness of the parts of the building, made in architectural decoration in this way. The profile contour of the template itself, from which the rusting of the seams is performed (stretched, cut out), consists of a standard set of lines — architectural breakages. Thus, it is possible to single out a list of rusticated plasters on their design of rustings:

In addition to the shape that the rustic has, the shape of the quadras are also important for the appearance - sections of planes that are framed / divided by the rust. They can be both flat and not protruding, or have the form of a broken stone or a prism, a pyramidal convex shape, and also a hollow rectangular shape. Greek Rust It has a small recess, like a rectangular one, but the difference is the alternation of rows of small and large rectangular stones, made with a seam of rust in the “wiring”. The squares themselves, imitating Greek stone, are flat (imitating ground stone). There is a slightly different kind of imitation - under the Roman masonry, when quadras imitate roughly hewn stone. Rectangular rust is the most common and does not have a special set of architectural breakups, the seam is a rectangular slot of moderate depth and can be performed when making squares in almost any shape. Especially it is used when rusticating plaster of small layer thickness. Rust Cut has a triangular cross section, tapering inwards. Such an imitation gives the impression of a special weight, massiveness of the blocks and gives them the shape of a trapezium due to the fact that the sharp, protruding angles are represented by bevelled. In order to perform such a rust, you need to perform a thick layer of plaster, or the brickwork must be made with grooves in places of rusting.

Rounded rust similar to the previous one, it is performed on a thick layer of plaster. Thus made rusticated plaster looks more harmonious with oval, semicircular elements of the building and light architectural orders, although, as they say, "the taste and color." The inner corners are sharp, the outer corners are absent, because they are radius, but the junction of the vertical and horizontal seams is performed without rounding. Grooved Rust it also consists of a radius and a square break, as well as a rounded one, only the radius is not straight, but reverse, which forms a seam in the form of a groove. Such a rust looks very broad (in general, the way it is) and when developing a sketch, it is important to calculate the size of the squares so that they do not look too small relative to such rusticated seams. Figured Rust It is already considered difficult, since it consists of a whole complex of architectural bounces. There is a lot of various combinations of architectural bounces, from which you can get a rusticated seam of the most diverse form. The width of such a rust can be very large, as well as the depth, therefore it is not possible to perform it on an ordinary layer of plaster (2.2 cm - maximum of SNiP). It is carried out exclusively in one way - by extrusion using a template. Facade decoration with rusticated plaster using traditional technologies

According to traditional technologies, the imitation of sections of the facade of a house under rusticated stone is made from ordinary cement or cement-lime plaster composition with application according to ordinary technology with the presence of coating and soil. At the same time, the work on the formation of rusting can be done on freshly wiped plaster, or they can be performed directly together with plastering. Anyway, there are several options for the execution of rust on the facade of the building, the list is as follows:

There are special design ventures when the rust itself is framed (fringed) with a pattern or a continuous strip drawn along the perimeter of the quadra. This frame is separately refined by hand tools, like the quadras themselves, in case they are performed with a relief or a certain form of ploskti protrusion.

There are several ways in which the renovation of the facade is performed by the template: pulling out one tape and pulling out two tapes. In the first case, the template forms only one strip of a rust seam, in the second, the template has protrusions for pulling two parallel rustos at once. In this case, the pattern can have the profile of the quadra itself, that is, in this way it is fashionable to simultaneously pull out two rustles and a figured quadra.

First, the horizontal slats are sunk, then vertical so that the crate is obtained. After the mortar begins to set, the slats are carefully removed and, if necessary, rubbed over the defects. There is also an amateurish way, when these slats are installed as beacons in, gluing them onto continuous strips of the solution, which is supposed to plaster the entire surface. When the solution is firmly seized, between the rails, as the beacons are applied the solution and level.

The formation of the rust itself is carried out in several working operations: cutting the lower boundary of the rust, the upper boundary and scraping the mortar between them (you can scrape it with a thin spatula, chisel). You can also wipe the seam itself with a piece of styrofoam cut in its shape and size.

In this case, it is very important to wait for a certain moment in which the mortar has not fully grasped, but no longer “float” from the vibration created by hammering the metal tool (ruler). The depth of the seam made in this way can be no more than 10 mm, and its shape can be rectangular, and it is especially convenient to make rusts in such a way.

The squares themselves are formed from these plate materials by placing them in compliance with the seam, and in the seam between them lay a special profile made of plastic or aluminum. The most common is a square section of the profile, but there are also all those species that have been considered rusticated by traditional technologies.

After that, either preparation for painting is done, which consists in applying a sandless coating, or preparation for painting (bark beetle, pebble, mosaic) and in this case the surface is treated with a primer paint with quartz sand filler. Thus, rusticated pilasters can be quickly and efficiently executed, as well as rusticated columns, in addition to walls, arches and many other elements of the building. As you can see, the work on modern technologies is performed equally regardless of the shape of rust. In addition, there are special shaped plates, rusta, which are generally not required in the finishing, except for painting except, but this already applies to facing works, and not to plastering. A rusting facade is facing the external walls of a house by creating grooves in the plaster, or by gluing elements that divide it into parts. What is rustika? This word is translated from Latin as "rustic", "rough", "uncouth". In architecture, this word is called tightly fitted to each other rectangular stones with a smooth line around the perimeter. This type was used in ancient Rome, thereby protecting the walls of the first floors of the building from moisture and noise, as well as from the blows of passing carts. Despite its old origins, rusticated facades in Russia appeared only in the 18th century and belong to the Neo-Renaissance style.  Rust creation methodsThere are several ways to create self-made rust.

Rust productionBefore creating, the surface of the wall is marked on the stones with a cord or ruler. Let's take a look at each of the ways to create rust on the facade. Rusty on expanded polystyreneOne of the most popular ways is the decision to create rusts simultaneously with the building's insulation with expanded polystyrene.

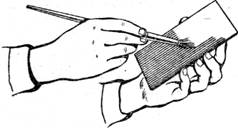

Packing with a ruler

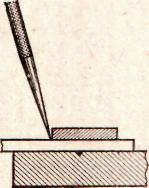

Saw bladeIf you want to get thin rusta, then use a saw or grinder. In this case, the final layer, which has already hardened, is cut. This work is most conveniently carried out by three: one worker creates indentations, and the other two move the stopper along the wall. This way you can achieve different widths of rust by making several parallel cuts, and the contents between them are knocked out with a chisel. Rough lines correct and rub with tricks. Wooden slatsWith the help of rails, you can create rusta wide width. To do this, smeared wooden slats with a trapezoid cross section are driven into the immature plaster. Depending on the desired depth, the slats are installed in a covering or primer plaster. When the solution dries, the slats are removed and the defective places are corrected manually. Extrusion during plasteringIt is also possible to draw out rusta during plaster. To do this, the surface of the frozen soil is divided into parts, the templates are hung, and simultaneously with the application of the final layer of plaster, the rust is drawn. If deep rusts are needed, the base under them is removed. Depending on the size and shape of rust, the work on their creation in this way is carried out together or together. Two workers apply the solution of the coating, the third holds the pattern. First, horizontal stripes are made, then vertical. When all lines are ready, they are rubbed with a smooth wooden lath, which is carried out through the previously created rustus. Fretwork The easiest way to create rusticated facades is to use ready-made decorative elements from expanded polystyrene. They are stucco, which is mounted on liquid nails or building glue. Installation of such elements is simple and quick, which is almost no different from sticking stucco inside the building.  ConclusionRusting facades is quite an expensive, responsible and time consuming process, but the result will look extraordinarily beautiful and luxurious. If you want to create a house in a classic style - the best solution for you is the use of rusticated facades. One of the most common types of facade decoration is finishing them under stones, which are separated from each other by rods. Rusty between the stones can be of different profiles: triangular, square or in the form of rods, consisting of architectural breakages (Fig. 194). Fig. 194. Forms of Rusto Before work begins, the surface of the facade is divided into stones with a cord or ruler. Along the lines of division on freshly applied plaster produce rusting or pulling them with templates.  Fig. 195. Stuffing rust with steel ruler Rust stuffing. A steel ruler (strip) 5–15 mm thick is attached to the intended line and a hammer is deepened into the layer of plaster by 5–10 mm (fig. 195). Then the line is carefully removed, so as not to tear the edges of rust. You need to have two rulers: one along the length of the vertical rust, the other - along the length of the horizontal. Rust cutting with a saw. It is produced by hardened plaster. For cutting rustit take a piece of a saw with a length of 20-30 cm with a handle attached on top. A well-planted rule is imposed on the planned lines of rust, according to which the saws of rust are made with a saw (fig. 196). Packing and cutting can be made rusta not wider than 15 mm.

Rust device using rails. In those cases when rusts must have a large width and smooth profiles (square, triangle), they are made with slats, which are dabbed into the solution. Reiki should be well-groomed. Quadrangular rails are usually given a trapezoidal section so that they are better removed from the solution. Depending on the required depth of rusting, the slats are installed in the ground or in the covering layer. The solution applied near the rails is well compacted with a scraper or a special tamper, so that it does not have sinks that require refilling and leaving stains on the colored plaster. Depending on the shape of the stone, the solution covers the space between the slats or only around the slats. For the formation of rust can be used and shaped slats raspedannye in the form of rust. For horizontal lines, the slats are made long, for vertical lines - short ones that should be cut into long ones and removed after applying the solution. It is necessary to point out that the use of shaped laths many times increases labor productivity in comparison with stretching the rust patterns. The arrangement of rust by means of rails is shown in fig. 197. The process of stretching the rust is no different from the stretching. |

Popular:

New

- How to rivet a rivet - automatic and manual methods for different materials What rivet rivet steel sheets

- Appointment of planar marking

- What should be used reinforcing mesh for concrete, wallpaper, plaster technology - plastic, fiberglass or metal

- Edit strip and sheet material

- Open lesson "editing, bending"

- Installation of staircases and platforms: general information

- Repair of pipes of water supply in the apartment Repair of steel pipes

- Markup definition. Planar marking. Types of markup. Questions for self-test

- Pipe bending machines Various variations of pipe bending machine

- Safety during filing

Such plastering is carried out not only on the planes of the walls and their individual sections, but also on architectural and constructive sections, such as the socle of a building, pylons, pilasters, columns, arches and many others.

Such plastering is carried out not only on the planes of the walls and their individual sections, but also on architectural and constructive sections, such as the socle of a building, pylons, pilasters, columns, arches and many others.

This option does not provide for the presence of a device for a thermal insulation layer that is so popular today. However, all the same, you can combine materials, especially you can take modern plaster compositions and do the work on the formation of rust by using them.

This option does not provide for the presence of a device for a thermal insulation layer that is so popular today. However, all the same, you can combine materials, especially you can take modern plaster compositions and do the work on the formation of rust by using them. produced as plastering on special guides (rules), which are mounted above and below the line of rust. In this case, the rust is performed on the freshly applied layer of soil and is formed by linear movements of the template on the rails.

produced as plastering on special guides (rules), which are mounted above and below the line of rust. In this case, the rust is performed on the freshly applied layer of soil and is formed by linear movements of the template on the rails. Perhaps the easiest way to perform work. Its essence is to “monolith” in a freshly applied and leveled layer of soil, that is, to drown the slats, repeating the profile of the rust. This is done by rubbing or vibrating with a light tap of the hammer on the rail.

Perhaps the easiest way to perform work. Its essence is to “monolith” in a freshly applied and leveled layer of soil, that is, to drown the slats, repeating the profile of the rust. This is done by rubbing or vibrating with a light tap of the hammer on the rail. can be used to ensure that the surface of the rusticated chalk is a thin and shallow rust. In this case, the work is carried out on a slightly strengthened, rubbed plaster according to a preliminary scheduled surface marking. In order to make even cuts, the saw is pressed against the rule that is firmly pressed against the surface to be machined.

can be used to ensure that the surface of the rusticated chalk is a thin and shallow rust. In this case, the work is carried out on a slightly strengthened, rubbed plaster according to a preliminary scheduled surface marking. In order to make even cuts, the saw is pressed against the rule that is firmly pressed against the surface to be machined. a rather complicated process whereby plaster has to be rustled with a tool no longer than a meter in length and the uniform depth of the seam being formed along its entire length is monitored. The ruler is laid according to the pre-made markup. Such rust can be obtained with a thickness of no more than 10 mm, the complexity of the whole process depends to a greater extent on the depth of implementation.

a rather complicated process whereby plaster has to be rustled with a tool no longer than a meter in length and the uniform depth of the seam being formed along its entire length is monitored. The ruler is laid according to the pre-made markup. Such rust can be obtained with a thickness of no more than 10 mm, the complexity of the whole process depends to a greater extent on the depth of implementation. Modern stucco rustic facade, that is, finishing it "wet" is carried out using a layer of insulation - mineral wool or polystyrene plates. Work begins with surface preparation, that is, leveling it with rough plaster (cement-sand / cement-lime or modern polymer-cement), laying a continuous layer of insulation, and then marking the lines of future joints.

Modern stucco rustic facade, that is, finishing it "wet" is carried out using a layer of insulation - mineral wool or polystyrene plates. Work begins with surface preparation, that is, leveling it with rough plaster (cement-sand / cement-lime or modern polymer-cement), laying a continuous layer of insulation, and then marking the lines of future joints. This profile has perforated planes that are adjacent to the plates, put them on the glue. Then everything goes according to the technology: fiberglass device on insulation plates for glue plaster composition and a secondary coating of the same composition on dried glued fiberglass.

This profile has perforated planes that are adjacent to the plates, put them on the glue. Then everything goes according to the technology: fiberglass device on insulation plates for glue plaster composition and a secondary coating of the same composition on dried glued fiberglass.