|

|

Study guide to prepare

production workers Workshop on plumbing

Connection of parts with hollow rivets

In the plumbing works there are various connections of parts made of metal, fiber, cardboard, leather, plastics, made by riveting with hollow rivets (pistons) (Fig. 258, a).

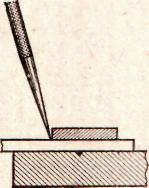

Fig. 258. Flaring of a head of a hollow rivet on the drilling machine:

a - hollow rivet; b - work reception

Rivet joints are performed in two ways: 1) by flaring the locking head on the drilling machine; 2) the formation of the closing head blows using a special swage. The method of flaring the head of the rivet on the drilling machine is more productive and is widely used for copper, brass and aluminum rivets. The rivet connection with the flaring of the head of the rivet is performed in the following sequence. 1. Mark and nip the centers of the holes for the rivets. 2. Drill all the holes included in the connection, or punch them on the presses with hole punching tools. 3. Assemble the connection, checking the correct location of the parts and all the holes, and then fixing them with screws. 4. Rivet lay the bottom and place it on the support. 5. In the chuck of the drilling machine set flaring, and the part on the table of the machine is placed in such a way that the axis of the flaring exactly coincided with the center of the hole rivet. 6. Turn on the electric motor and flare the closing head of the hollow rivet. In the process of flaring the head of the rivet, the machine spindle should be lowered smoothly without much pressure on the lever, controlling the formation of the head until a convex ring of the correct shape is formed (Fig. 258, b). Flaring periodically greased with petroleum jelly.

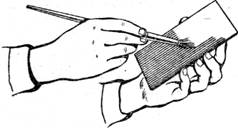

The second method of connecting parts with hollow rivets using special crimps is carried out in two steps: - the first reception - the rivet put in the hole is placed on the support and the end of the rivet is distributed by hammer blows to the corener (fig. 259, a);

- the second technique — a crimp is installed on the upset end of the rivet and with a hammer blow on the crimp forms the locking head of the hollow rivet (Fig. 259, b).

Fig. 259. Reception of riveting of parts with hollow rivets:

a - pre-rivet core; b - final riveting mandrel, in - mortgage washers In order not to damage the surface of the part with the head of a rivet when joining several sheets with hollow rivets, metal washers are placed under them (fig. 259. c). |

The rivet is a disposable fastener designed to hold 2 or more parts together. To install this fastener, use a riveter. How to remove the rivet will have to proceed from the availability of available tools, because there is no universal tool. In addition, the selection of metal materials is made in accordance with the technical characteristics.

Aluminum, copper, steel differ in hardness, in varying degrees, they are subject to diffusion, oxidation rates and other physicochemical processes. The only way that can be called almost universal is drilling. This process can be carried out in 3 ways, which in most cases depends on how much the fastening metal is related to with the fastened elements.

The way to remove the rivet

The rivet is somewhat easier to remove. When dismantling it, it is necessary to remove the ring formed during fastening. If there is a possibility, when compressing the material of the structure, insert the file on the metal file, the fastening can be cut off, and the pin can be removed by pulling out the rod. If you can not cut or cut, there is always a chance to remove the mount on the first method - drill out.

The secret fastening can be removed only by drilling, and the exhaust heads can be knocked down with a hammer, if the strength of the material fastened by them is greater than that of the fastener itself. Provided that using this method of dismantling, there is no confidence in 100% safety for your own hands and the appearance of the material, it is better to refuse it.

Rivet and Riveter. Device zaklepochnik and rivets. How to work as a riveter. Tool.

Section. Construction tool

Riveter - a tool designed to perform riveting work. The connections on the rivets are a non-separable combination of two or more parts by filling the connecting hole with some kind of metal. In the classic version - in the details they make an adjacent hole, and countersink it from opposite sides. A small piece of soft metal is inserted into the hole and flattened out so that the metal fills the entire hole and the countersink grooves. The resulting "caps" and keep the parts together. Of course, with the help of rivets, you can plug (rivet) a hole and just in one piece.

The connection on the rivets is very reliable and most importantly - very vibration resistant. The rivet will never burst "suddenly" with an increase in the tensile load applied to the parts. This distinguishes rivet joints from welding, which bursts all at once. The rivet will first "stretch." Low cost of rivet compares favorably, as the rivet itself is just a small piece of soft wire. Of course, with the advent of machine tools, they also began to make blanks from wire in the form of blanks for riveting.

The classic riveting process requires rivet access from two sides. After all, the effort for forging metal is quite significant. If the details are small, the detail is placed on the anvil with the finished cap, and if the larger ones, they rest on the side of the opposite forging. It was extremely inconvenient and made the process strong in fact a lot of professionals or industrial production.

But modern rivets (so-called rivets) allow work only on one side. What made riveting work very affordable and popular. All this happened thanks to a change in the design of the rivet and the appearance of a special tool - a riveter. A modern construction rivet is a small tube, with a finished cap on one side (Fig. 3). A piece of wire is inserted into the tube, also with a cap on the other side. If this wire is forced to be pulled through this tube, then a strong wire cap will flare the tube. And when the wire cap rests on the part, the wire will simply break, and the tube will remain flared. For connecting thin parts into which it is impossible to screw in a screw or make a screw connection, rivets are simply indispensable.

Zaklepochnik itself is a manual lever mechanism with a large ratio of arms leverage. The drive is carried out on the collet mechanism, which seizes the wire of the rivet, and resting on the finished head of the rivet, pulls it towards itself and cuts it off. Riveters on the design can be simple, but there are also with "amenities". For example, in the form of a swivel collet head, allowing the use of zaklepochnik in hard to reach places. Since the rivets are different both in diameter and in length of the rivet tube, the riveter has a set of interchangeable heads for different wire diameters.

The installation of the rivet takes about a couple of seconds (if the holes in the parts to be joined are ready). Let's show it by example.

Suppose you need to connect two parts of a sufficiently thin metal, and access to them is only on one side. Well, for example, it is necessary to attach (conditionally) handles to the barrel, or legs ... You cannot cook (non-ferrous and dissimilar metal), self-tapping screws will not hold in a thin metal (they need at least 1.5-2 "threads", i.e. revolutions of the thread). Soldering is impossible, the details are massive. It is unreliable to glue, glues work well for shear, not for tearing. It remains only to be riveted ...

1. Attaching the parts to each other, drill a through hole in both parts.

2. Insert the rivet into the hole. The length of the rivet tube should be such that it would protrude from the opposite side by about 1 cm. There is no longer any point, and less - there may not be enough metal to expand and form a reliable cap.

3. On the protruding wire we put on the head of the riveter, press it to the cap and press down on the handles.

4. Do this several times until the wire breaks. Rivet ready!

5. Since this is just an example, let's see how the rivet looks from the opposite side. Also quite neat head.

The wire head remaining in the flared tube can be knocked out with the help of a broken piece of wire. Then, in place of the rivet, a small neat hole is formed that is rimmed in a circle. This rivet can be used for cutting threads in thin metal. Those. if we need to make a threaded connection in a thin metal, we first drill a hole, rivet it, and then, knocking out the head of the wire, cut the thread in the rivet.

The use of zaklepochnik (and technologies of riveting work) greatly facilitates some construction and installation work and allows you to quickly make reliable connections of various parts.

http://dom.delaysam.ru

Quite often, home craftsmen fasten various metal joints together, it is here that hand riveters become very relevant, because with them the connection is made quickly, firmly, and without great physical effort.

Introduction

It should be noted that this mechanism is very easy to use, and the usual model is inexpensive. With it, you can fasten any type of metal, and the principle of operation remains the same.

Of course, you can make a rivet with a hammer, but with a large amount of work it will take much more time and effort. Riveters manual allow you to make the workflow faster, and efforts on all ongoing operations - minimal.

Today, there are various types of manual zaklepochnikov, each works according to its principle, has its own pros and cons. What type of riveter is better, each master himself determines, but it needs to take into account a few points, which we will consider below.

general description

Modern zaklepochniki appeared relatively recently, before that they were bulky and inconvenient for home use. But the constant work of engineers on this problem has given its results: riveters manual became compact, and most importantly, securely connect the parts with each other with minimal physical effort. The device itself has become quite simple and easy to use.

It provides an approach to both sides for a more reliable connection. In this case, outside assistance is not required. The main thing that is needed in working with manual riveters is pre-drilled holes for rivets in the connected parts.

Almost everyone will be able to cope with such work. At the same time, the price of hand riveters is low.

Varieties of hand tools

To date, there are two types of manual zaklepochnik: exhaust and threaded, the difference in price they are not big.

To answer the questions: how to choose a hand, exhaust or threaded riveter, which tool is better, you need to understand their working principles.

When using an exhaust riveter to attach the rivet, a certain tractive force is created.

In metal blanks, which will subsequently be interconnected, you need to drill a hole whose diameter is equal to the diameter of the rivet. After that, fix the rivet on the fixture, insert it into the hole and squeeze the tool handle.

During operation of the riveter, the riveting is opened by a special ball, which, when the handle is pressed, enters the tube.

Thus, the outer side of the rivet flattens out, which allows you to firmly fix the joined parts to each other.

For domestic work and suitable screw riveter manual type. The principle of its action is almost the same as that of the previous mechanism. The only difference is that in the threaded riveter the ball retracts due to the fact that the cut thread rotates.

More optimal is the connection for thin-walled parts, where it is quite difficult to cut the thread, but you need just such a connection.

When using a threaded hand riveter, there is the possibility of screwing a screw or bolt into the rivet.

In most cases, home-made rivet rivets are used for home use, they are still more functional and versatile, while they cost a bit less than threaded tools.

Different types of drive

The most common are manual riveters, but there are also devices with different drives. They are pneumatic, pneumatichydraulic, and also mechanical. Of course, each type has its own price. It also depends on the manufacturer - the more well-known brands, respectively, the price will be higher.

Pneumatic and pneumohydraulic tools are mainly used in production, since the device they have is more complex. At home, it is better to use manual riveters. When buying with them in the kit are removable heads, which allows the use of rivets of different diameters. Also, the head of the required size, as well as rivets for a manual riveter, can be easily purchased in the store.

Connecting parts with a tool

As mentioned above, the most popular in everyday life is a manual-type riveter. The structure of this device includes a sleeve and rod. And now we will understand how the riveter manual exhaust type.

First, the sleeve is inserted into a pre-prepared hole, after which we take the riveter, which retracts the rod. It will only press on the handle of the tool and the sleeve flattened, forming a strong and reliable fasteners. All this will take very little time and effort.

This device has its advantages. Firstly, it is possible to work with it even when only one side of the blank is free. You can also use a manual riveter even on weight, without using other additional elements.

Of course, you should not forget about the quality of the rivet itself, the fastening reliability also depends on this.

Manual riveter: how to use

Using hand tools is easy, you do not need to acquire special skills. Properly acquired mechanism will do this job efficiently and quickly. The price when buying a tool should not play a big role, the main thing is to choose a model of good quality. This will allow not to worry about the density of the connection and the failure of the tool.

It is only necessary to drill the holes correctly so that the diameter exactly matches the diameter of the rivet itself. We have already described the work of the riveter in detail above. After work, it will only be necessary to process the opposite flattened side of the rivet, that is, to remove the excess formed with a nipper.

Manual riveter: reviews

Very good reviews from the masters earned riveter Stanley MR99. The pins do not get stuck, fly out without help. Of course, not the cheapest, but it is important to work well.

The NOVUS J 60 riveter has also been in demand for a long time on the market, which is confirmed by numerous customer reviews. It works well, there are no problems. But suitable for one-time work, as with large volumes tired hands. Its swivel head is very relevant, it makes the tool even more convenient.

The riveter company Topex has proven itself quite well with the consumer. It is inexpensive, suitable for one-time work. Very convenient that the spout can be rearranged to 90 degrees. It gives the chance to rivet in the most inconvenient places.

Also, positive feedback from customers was received by the GESIPA NTS riveter, which is not cheap for the price, but the German quality does not fail.

How does the riveter work?

The builder or person associated with loading and unloading large metal structures and materials knows the answer to this.

And for all other people interested in the mechanism of operation of this tool, an explanation is given below.

Zaklepochnik is a mechanical tool that allows you to quickly and accurately fasten together sheets, the thickness of which is three millimeters.

With the same ease, he connects the profile and the corner with each other.

In order to carry out the riveting process, it is necessary first to do the preparatory work.

Namely: drill a hole at the intended junction.

In this case, both ends of this workpiece must protrude from the fastened planes or parts. When repeatedly pressing the handle, there is a gradual flattening of this part.

When the upper part of it is as flat as possible, the mount on one side will already firmly hold, leaning on the “thick” part.

After the end of the riveting process, the lower “tail” of the riveted part is bitten off with a special tool. You must always take into account the thickness of the fastened parts. They need to choose the appropriate size of attachment. For example, for metal sheets with a thickness:

- Up to half a millimeter need to rivet rivets with a size of 2.4 mm.

- Nine and a half centimeters - 3.2 mm.

- Twelve and a half millimeters - from 4 mm to 4.8 mm.

At the same time, the hole for each rivet must be drilled one millimeter larger than the diameter of the rivet. Accordingly, for a part with a width of 2.4 mm, the hole will be made, with a thickness of two and a half millimeters, 3.2 mm - 3.3 mm, for 4 mm - 4.1 mm, for 4.8 mm - 4.9 mm .

The strength of any rivet size is determined not by its size, but by the quality of the metal, and the power of the resistance that the structural elements have that was made using rivets. If this pressure is large, a softening or deformation of the metal rivet gradually occurs.

The work of the tool is based on the effect of flattening due to targeted pressure on a certain part of the piece (workpiece).

Rivets and work with them

The explanation of how manual riveter works cannot be complete without considering the types of riveting tools (consumables - rivets).

There are two fundamental types of these parts: monolithic, that is whole, and tubular.

The latter are usually called caps.

All-metal rivets are more like just a piece of thick wire and are used only for the manual type of riveting.

Much later, the beginning of the use of the described appeared more used now caps - the second type (inside - a soft metal, which is quite easily flattened when pressed).

Most importantly, these parts are further subdivided into two subspecies: nut and exhaust. The latter contain two parts: the tube and the inside, the so-called Poisson or rod.

On top of such a simple construction is an enlarged part - a cap, which prevents the rivet from protruding or breaking. Poisson is inserted from the reverse side, that is, from the opposite side, where the cap is located.

It turns out that rivets are subsequently inserted from two sides, subsequently flattened out.

How does zaklepochnik for threaded rivets?

The principle is the same, and the peculiarity of the rivet material, which, after screwing (hammering) into the structure, is bitten off by a special construction tool.

And besides, the length so you can choose any.

When it comes to large volumes of rivets, you need to take the so-called professional mechanism that allows you to make more rivets, while making less effort.

A slightly more complicated mechanism (except for the manual one) is called a pneumatic riveter. His work is due to compressed air.

Pneumatic devices need a compressor. There are professional mechanisms which contain a hydraulic press in their design.

Such a riveter is called pneumohydraulic. As it can be seen from the definition, it works due to two kinds of mechanisms that activate the main work item.

To choose a tool for making a sharp rivet joint of metal parts, including sheet metal and profiles, you need to take into account the thickness of the fastened material.

More information about pneumatic zaklepochnik presented in the video:

Noticed a mistake? Select it and click Ctrl + Enterto let us know.

Manual zaklepochnik - the tool intended for a fastening of sheet materials. Most often, rivets fasten sheets of metal with a thickness of up to 3 mm, but you can attach a sheet of metal to a profile or a corner. We have a riveter exhaust, the principle of its action is slightly different than the riveting of ordinary rivets and a hammer. In this article, we will look at the main types of riveting hand tools, how to pick up rivets and how to use this device.

How to work as an exhaust riveter

First of all, it is necessary to drill a hole through both fastened sheets through. The diameter of the hole should be the diameter of the rivets. Then we “charge” the rivet and insert it through both sheets and begin to squeeze the handle (more than one compression will be needed). The rivet begins to flatten when the ball retracts completely into the rivet — the tail of the rivet is bitten off. As a result, we have 2 sheets of metal riveted on both sides. In the photo below you can see the instructions in the pictures.

Video - how to rivet

We took a video with your partner, how to use a zaklepochnik. I hope it will help you understand how and what to do.

What are the riveters:

Normal inexpensive model

Take, for example, the cheapest option from the company Stayer - the very first photo. Its cost is 300 rubles. It supports all the diameters of the rivets (2.4 mm, 3.2, 4 and 4.8 mm), so that you can choose the diameter of the rivets most suitable for the materials being fastened.

For example, thin rivets with a diameter of 2.4 mm are intended for fastening sheet material with a total thickness of up to 5 mm. Of course, there is also such a parameter of rivets as length. The longer the rivet, the thicker the material can be stapled.

I bring to your attention a table of the ratio of the size of the rivets and the thickness of the material.

Riveters with swivel "head"

It differs from the usual in that the head of the riveter can rotate 360 degrees. It helps a lot when working in hard-to-reach places, where the usual is not to crawl. True and it is more expensive, about 350 rubles. We also consider the model of the company Stayer.

Reinforced models (two-handed)

For people who work zaklepochnik constantly, release power options.

They differ from the usual ones in that they squeeze it with two hands, respectively, the forces are considerably saved. Imagine that you need to rivet 500 rivets. An ordinary zaklepochnik such a volume of work will be difficult to perform, but with reinforced everything can be riveted much faster and without tension. Looks like reinforced - in the photo below.

Professional models with extended service life

In addition to household models for homework, there are professional ones for sale. Differ from household more high-quality execution and the increased service life. For example, the model of the company kraftool. The usual, not rotary model, however costs much more expensively. In the photo below Kraftul's riveter is the price of 400 rubles.

All riveters in the kit come with 4 interchangeable nozzles for different rivet diameters. They change with the help of a special key, which is also included.

Rivets are usually sold in small packages of 50 pieces. The rivets differ in diameter and length; the thicker and longer the rivet, the more expensive the packaging. For example:

- 3.2 * 6 mm - the price is 26 rubles

- 4 * 12 - the cost of 35 rubles

- 4.8 * 16 - 50 rubles

When buying consumables do not forget that the rivets are needed for riveting, exhaust. And then the shops are sold and the usual, which are riveted with a hammer.

Rivet joining of parts is a very popular method used today in construction, manufacturing and everyday life. To install such fasteners in metal elements is applied. This is a simple tool, in the working head of which there is a holder into which the fastener is inserted. In the blanks, a hole is drilled into which the rivet is placed, and when the tool lever is pressed, it is flattened, fixing itself in the material. Everything is very simple! Someone will say why to use such a method, if there are others to connect metal elements, for example, welding or fastening with screws. But not in all cases they are applicable. Here are some examples.

- It is necessary to perform the connection of metal parts and at the same time eliminate the change in their structure.

- Do not heat metal or surfaces adjacent to the elements to be joined.

- It is necessary to combine parts from different materials for which welding is not applicable.

- It is necessary to fix hard-to-reach structural elements, and the impact of the tool is possible only on one side.

- There is the likelihood of fatigue cracks from part to part when they are connected.

Then apply zaklepochnik, which helps solve all these problems. What else is this tool good for? Let's see.

The advantages of joining parts with rivets

This type of fastener has been used since time immemorial, for example, it can be found in military armor. By the way, in the construction of the Eiffel Tower and the Aurora cruiser, rivets were also used, only of a much larger size, compared to armor fasteners. Now such elements are used in construction, for example, when installing fences, installing frames of ventilated facades, fastening steel sheets to a profile; in production at the connection of metal parts of aggregates, machines, boiler equipment; in everyday life during repairs. Not surprising, since the zaklepochnik has so many advantages!

Easy to work with

Riveting is a fairly simple method of joining parts compared to, for example, welding and is much more secure. It is only necessary to pick up the rivet of a suitable diameter and install it in the drilled hole. To get your hand, just install a few elements!

It turns out a reliable and aesthetic mount

For example, you need to connect metal and wood blanks. Riveter will cope with this task, and the connection will be very reliable. The rivet installed in the drilled hole firmly fixes the parts, does not deform them and prevents fatigue cracks from spreading. The fastener rod is bitten off, and a neat hat remains on the face of the part, which looks very aesthetic and does not spoil the appearance of the product.

For example, you need to connect metal and wood blanks. Riveter will cope with this task, and the connection will be very reliable. The rivet installed in the drilled hole firmly fixes the parts, does not deform them and prevents fatigue cracks from spreading. The fastener rod is bitten off, and a neat hat remains on the face of the part, which looks very aesthetic and does not spoil the appearance of the product.

Minimum tool and fastener costs

The cost of a riveter is much lower than, for example, a welding machine. An amateur model can be purchased at a price of up to 1000 rubles, a professional will cost more, but it will help to achieve a higher productivity of work. As for consumables, the price of rivets is small. For example, a pack of 50 pieces costs about 40 rubles.

. For comparison, when installing the frame for the ventilated facade on 1 square. m accounts for about 20 rivets - for this you spend less than 20 rubles. And if you take a pack of 1000 pieces, then fasteners will be even cheaper. In the conditions of construction and production, where you have to use rivets in large quantities, this option will be very profitable.

As you can see, riveted joints are the best method when you need to connect metal elements, spending a minimum of money and effort on this. If you decide that a riveter is needed in your work, do not rush to buy the first model you like. There are several types of tools: some are used in private construction, others are designed for intensive loads in the field of production. We will tell about each in more detail.

As you can see, riveted joints are the best method when you need to connect metal elements, spending a minimum of money and effort on this. If you decide that a riveter is needed in your work, do not rush to buy the first model you like. There are several types of tools: some are used in private construction, others are designed for intensive loads in the field of production. We will tell about each in more detail.

Types of riveters

The division of the instrument takes place not only according to the principle of “everyday / professional”, but first of all according to the way it works. There are two main parameters for classification.

By type of food

- Hand held - the simplest devices that are affordable, moreover, they can be used in any conditions: at high humidity and dust, at height, when there is no power supply, etc. Two-handed

Zaklepochniki have two handles that are compressed with two hands to transfer force to the working head - this is necessary for the deformation of the rivet. Such a tool is based on the lever principle; therefore, the productivity of work depends directly on the user effort. For a comfortable grip rubber pads on the handles are provided, as well as grooves for the fingers. The most versatile tools with a swivel head: they are suitable for work in hard to reach places. Models kulisnogo type

they have one handle and a scissor mechanism, through which the force is transmitted to the working head - for this you need to push the handle with force. This design is very convenient if you need to install a variety of fasteners. Most often, manual riveters are used in private construction, as well as installation teams and small workshops, where the installation of rivets is auxiliary.

- Rechargeable - externally represent a pistol and have a built-in battery that generates the energy for a strike, which is necessary when installing rivets. Therefore, the user makes less effort when working compared to a conventional riveter - you just need to press a button. Even with prolonged work, the load on the hands is not felt. Depending on the capacity of the battery, its charge is enough to install from a few hundred to several thousand fasteners. Like all hand tools, such models are used in facilities where there is no power supply, but, like any battery tool, it is not designed to work in high humidity and dust. This is a great option for use in the workshop or installation work.

- - the most productive type of devices, since the energy to install the rivet comes from a source of compressed air - a compressor. But the design of such a tool is more complicated: in addition to the pistol itself with a trigger and a working head, it also has a cylinder for compressed air and a pusher. Work requires connecting the tool to the compressor via a hose. It is important to remember that pneumatic riveters should be suitable in terms of operating parameters to the source of compressed air. The working pressure and air flow of the instrument must not exceed the corresponding compressor parameters. As a rule, such models are used in the manufacturing sector, when, during the assembly of products, the installation of rivets is the main workflow and occurs almost continuously. In this case, the manual model will not work because of the low productivity of work, and the battery model due to the limited battery charge.

By type of fasteners used

- For rivets - the most common type of tool. The fastener exerts a pulling effect when the tool handles are pulled together or the trigger is pulled. As a result, a riveted head is formed at the base of the element, holding it in the workpiece. The rod remaining from the rivet is ejected.

- For threaded rivets - Models that are used primarily in industry. The fastener is installed by flattening it in the prepared hole, and the fastener is screwed onto the holder. The rivet itself is hollow inside and has an internal thread - thus, the hole in the metal is strengthened by it, and it is the basis for screwing in bolts and screws.

Based on your own tasks, choose the appropriate tool. For example, you are planning to build a fence in the country - you will attach a professional sheet to the pipes. Take a manual riveter for rivets with two handles. If you are looking for a tool for daily work, for example, in the manufacture of ventilated facades, choose either the manual model of the rocker type or the battery model - it all depends on the operating conditions and the amount of work. To equip a production workshop or a workshop, the right decision will be to purchase a pneumatic riveter, with which labor productivity will be much higher.

Pay attention to what determines the functionality of the tool and productivity of work. Knowledge of the basic characteristics will help you make a successful purchase - you will select the model that best suits your needs and the specifics of the work.

Important selection options

The main characteristic is the thickness of the fastened blanks. Decide which sheet metal or profile you will join - their total thickness should not exceed the allowed value of the riveter. For example, the model is 8.5 mm. The next parameter is the size of the rivets used. For example, the tool has 4 interchangeable nozzles for working with fasteners of 2.4–4.8 mm in size, and a - 5 attachments for fasteners of 3.2–6.4 mm in size. These models are suitable for a wide range of jobs. If you plan to perform one specific operation that requires a certain size of fasteners, do not need such a functional model. Do not forget about the complete set of tools. Many manufacturers include not only replaceable nozzles, but also keys for maintenance. The pneumatic dresser has replaceable sponges and a container for waste materials, which ensures the safety of work - the rods fly off into the container, and not towards the operator. The model has a case and a set of rivets to get started.

The main characteristic is the thickness of the fastened blanks. Decide which sheet metal or profile you will join - their total thickness should not exceed the allowed value of the riveter. For example, the model is 8.5 mm. The next parameter is the size of the rivets used. For example, the tool has 4 interchangeable nozzles for working with fasteners of 2.4–4.8 mm in size, and a - 5 attachments for fasteners of 3.2–6.4 mm in size. These models are suitable for a wide range of jobs. If you plan to perform one specific operation that requires a certain size of fasteners, do not need such a functional model. Do not forget about the complete set of tools. Many manufacturers include not only replaceable nozzles, but also keys for maintenance. The pneumatic dresser has replaceable sponges and a container for waste materials, which ensures the safety of work - the rods fly off into the container, and not towards the operator. The model has a case and a set of rivets to get started.

In your arsenal there is no zaklepochnik yet? Then it's time to buy it! Having tested it in business, you will be convinced that it is very easy to carry out reliable rivet connections. You can choose a suitable model on our website and immediately purchase the necessary fasteners for work. Place an order now - you will receive the goods as soon as possible with delivery or you can pick it up at the nearest point of issue.

This very specific tool has a number of other names - “klepocnik”, “rivet gun”. Manual riveters are purchased mainly for domestic use, as they are simpler and cheaper than their counterparts. However, their range is quite impressive, and the cost of individual products is significantly different - from a hundred and fifty rubles to 2 - 3 thousand. Which zaklepochnik better to buy?

The main rule when choosing any "device" - what is it necessary for? After all, it is clear that manual models are inferior to professional and in versatility, and in performance. In other words, you need to clearly define the tasks that will have to be solved.

By the way, if you have to work often, and use rivets of different sizes, then it is advisable to have at least 2 different products in the “parameters”. For example - one-handed model + two-handed. But if business is put "on a stream", it is better not to spend money for cheap products. In any case, the riveter pays for itself completely, as well as.

What to focus on

Riveting material

If it is aluminum, then it is easy to work with it, so it does not matter which “klepocnik” is chosen. Harder with steel, so the device should be chosen more powerful.

Ease of use

First, the tool is one- or two-handed. Naturally, the latter can create more pressure, so it allows you to work with fasteners from any material of different sizes. Although in some cases (for example, limited space), you will only get one-handed.

Secondly, the design of the head. If it swivels, it creates additional convenience. Sometimes you have to rivet in difficult areas (in "uncomfortable" places), and this feature of the tool helps a lot.

Third, are there replaceable attachments for fasteners of various sizes? This can not comment.

Adaptations

Some models have a special “container” where “waste” is dumped. For example, when you have to rivet the roof or build a fence out of a profiled sheet, small parts of the metal fly around. If they are in the grass (sand, on the ground) around the place of work, then problems cannot be avoided, especially with children - they like to run barefoot in the summer.

Some "home craftsmen" prefer for a long time not to think about which tool to buy. If the amount of work is insignificant, they immediately buy a couple of cheap models. In the event of a single failure, there is always a spare on hand. A 150-200 rubles - not such a lot of money to go and ask the price. Although this point of view is not suitable for everyone, it also has the right to exist.

There is another opinion. It is better to buy a professional model for 700 rubles, and this will guarantee that it will last long enough. Especially since, perhaps, the riveter will need more than once.

It is necessary to take into account such factors as the accuracy of the owner. We do not pretend to the authorship of thought, but, nevertheless, say - you can break anything, no matter how much "it" cost. Therefore, one should not trust the reviews of people about a particular model, especially unfamiliar ones.

Considering the above, one should not be surprised by the opinion of professionals that the choice of a hand-held “klepochnik” is akin to a lottery - do not guess if you are lucky or not.

The object that is intended for riveting works is called a riveter. If two or more parts have a nonseparable connection, which is created by means of a connecting hole, some metal is called - connections on rivets. The classic version is an adjacent hole, made in detail, which countersinks from its opposite sides. Some are wondering: how to rivet a rivet? Usually they do it this way: a small piece, usually of a soft metal, is inserted into the hole made, and after it is flattened out, so that the metal completely fills the entire hole and all the countersink cavities. After this, caps will appear at the attachment point, which hold the parts together. Of course, with the help of the rivet there is an opportunity to rivet the hole just in one piece. You can order windows on the website http://perfect.gk.ua/ru/c-ivano-frankivsk.

Advantages of rivet joints

All connections made on rivets have increased reliability and useful quality - vibration resistance. If an increased load is applied to a part, then in no case will it suddenly burst. This greatly distinguishes the fastenings on rivets made by welding, which, if it bursts, then the whole bursts. At first, the rivet will stretch a bit. Unlike a screw joint, a rivet is very cheap because the rivet itself is just a small cylinder made of soft wire. When the machines operating in automatic mode appeared, they began to produce billets from wire, which look like blanks for riveting.

In the classic riveting process, access to the rivet is required on both sides. Because you need to make a lot of effort when forging metal. If the part is small in size, then it lies on the anvil with a finished cap, and if the part is large, then it is necessary to arrange an emphasis on the side that is opposite to the forging. Such a process is very inconvenient, and it left the opportunity to engage in such a business only to professionals or in industrial production.

But now modern rivets require work only on one side. Therefore, riveting work became popular and accessible. And now many can learn how to rivet a rivet and do it yourself. Thanks to the new design of the rivet and the new invention - riveter, all this happened. Now, modern rivet, which is used in construction, looks like a small tube with a finished cap on one side. A small wire is inserted in the tube and with a hat on the other side too. If this wire is pulled through with a tube, then the cap of the wire will begin to flare the tube. When the cap of the wire rests on the part, the wire simply breaks off, and the tube will be flared. In order to connect thin parts, rivets are necessary, especially if it is impossible to screw in a screw or make a screw connection.

Riveting tools

By itself, zaklepochnik looks like a manual mechanism with a lever system and a large ratio between the arms of the levers. The drive on the collet mechanism is made, it seizes wire in a rivet and rests against the finished cap, pulls it and breaks it. Riveters are of several types, they are standard, and sometimes with various additions. For example, there is a collet head, which unfolds, which means that it helps to reach hard-to-reach places. Complete with a zaklepochnik usually comes with a set of interchangeable heads, because the rivets are different in their length and diameter.

The riveting process itself takes no more than a few seconds if there are ready holes in the parts for joining. This can be seen in the example of how to rivet rivets.

For example, you need to connect 2 parts that are made of very thin metal, and you can only get close to them from one side. You can conditionally attach handles or legs to the barrel. You can not cook, because the metal is non-ferrous, and the screws will not be able to hold, because the metal is thin. You can not solder them either, because the details are massive. And the attachment is not very reliable, because the adhesives work well only for shear, but not for tearing. And it remains only to rivet.

- First you need to attach the parts to each other and drill a through hole in them.

- Now it is necessary to insert a rivet into the hole. The rivet tube should protrude from the back side by no more than 1 cm.

- Now you need to put on the head on the protruding wire and press it to the hat by pressing the handles.

- This should be done until the wire breaks, usually enough 1 time.

Such a rivet will not be completely completely airtight, if a hermetic seal is necessary, then additional measures will have to be taken, such as the use of silicone, a sealant with non-drying properties, epoxy putty, and others.

In the flared tube, the head of the wire will remain and it can be knocked out with the help of a piece of wire that has come off. After that, a hole will appear in the riveting place, from the rivet, which will not look quite neat. Such a rivet is sometimes used in threading thin metal. This means that if you need to make a threaded connection on a thin metal, then the first thing to do is to drill a hole, rivet it, and after knocking out the wire head, you need to cut the thread in the rivet.

For example, you need to connect metal and wood blanks. Riveter will cope with this task, and the connection will be very reliable. The rivet installed in the drilled hole firmly fixes the parts, does not deform them and prevents fatigue cracks from spreading. The fastener rod is bitten off, and a neat hat remains on the face of the part, which looks very aesthetic and does not spoil the appearance of the product.

For example, you need to connect metal and wood blanks. Riveter will cope with this task, and the connection will be very reliable. The rivet installed in the drilled hole firmly fixes the parts, does not deform them and prevents fatigue cracks from spreading. The fastener rod is bitten off, and a neat hat remains on the face of the part, which looks very aesthetic and does not spoil the appearance of the product. As you can see, riveted joints are the best method when you need to connect metal elements, spending a minimum of money and effort on this. If you decide that a riveter is needed in your work, do not rush to buy the first model you like. There are several types of tools: some are used in private construction, others are designed for intensive loads in the field of production. We will tell about each in more detail.

As you can see, riveted joints are the best method when you need to connect metal elements, spending a minimum of money and effort on this. If you decide that a riveter is needed in your work, do not rush to buy the first model you like. There are several types of tools: some are used in private construction, others are designed for intensive loads in the field of production. We will tell about each in more detail. The main characteristic is the thickness of the fastened blanks. Decide which sheet metal or profile you will join - their total thickness should not exceed the allowed value of the riveter. For example, the model is 8.5 mm. The next parameter is the size of the rivets used. For example, the tool has 4 interchangeable nozzles for working with fasteners of 2.4–4.8 mm in size, and a - 5 attachments for fasteners of 3.2–6.4 mm in size. These models are suitable for a wide range of jobs. If you plan to perform one specific operation that requires a certain size of fasteners, do not need such a functional model. Do not forget about the complete set of tools. Many manufacturers include not only replaceable nozzles, but also keys for maintenance. The pneumatic dresser has replaceable sponges and a container for waste materials, which ensures the safety of work - the rods fly off into the container, and not towards the operator. The model has a case and a set of rivets to get started.

The main characteristic is the thickness of the fastened blanks. Decide which sheet metal or profile you will join - their total thickness should not exceed the allowed value of the riveter. For example, the model is 8.5 mm. The next parameter is the size of the rivets used. For example, the tool has 4 interchangeable nozzles for working with fasteners of 2.4–4.8 mm in size, and a - 5 attachments for fasteners of 3.2–6.4 mm in size. These models are suitable for a wide range of jobs. If you plan to perform one specific operation that requires a certain size of fasteners, do not need such a functional model. Do not forget about the complete set of tools. Many manufacturers include not only replaceable nozzles, but also keys for maintenance. The pneumatic dresser has replaceable sponges and a container for waste materials, which ensures the safety of work - the rods fly off into the container, and not towards the operator. The model has a case and a set of rivets to get started.