Site sections

Editor's Choice:

- Bedroom design options in blue for a couple

- How to paint wallpaper for painting: tips and tricks

- Kitchen design in Khrushchev: useful tips for those who have a small kitchen

- How to punish noisy neighbors from above

- Design of a nursery for children of different sexes

- Shower cabin in the interior of a small bathroom

- Which light is better - warm or cold

- How to care for recently pierced ears

- What to do if the neighbors above are constantly poured

- Materials used for suspended kitchen ceilings

Advertising

| Jumper reinforced carrier. Crossing points reinforced concrete |

|

Reinforced concrete is widely used in modern construction. The material is characterized by high strength, resistance to external influences, durability. When building buildings from piece materials (brick, cinder block, aerated concrete blocks), it becomes necessary to overlap the door and window openings. For these purposes, use a special type of concrete products - lintels. PurposeLintels are based on the masonry walls and transmitting to them the load overlying the masonry and floors. Structurally, the jumper consists of a reinforcing cage and heavy concrete. In practice, prefabricated reinforced concrete products are used, either monolithic, manufactured on site. In this case, the brands of the products used and the area of their support should be determined by calculation taking into account the collected loads. StandardsThe main parameters of prefabricated products defines GOST "Reinforced concrete lintels for buildings with brick walls". This standard defines the classification, brand, size and characteristics. Jumpers are divided into:

For the production of standard products, a set of typical working documentation has been developed - 1.038.1-1, including working drawings.

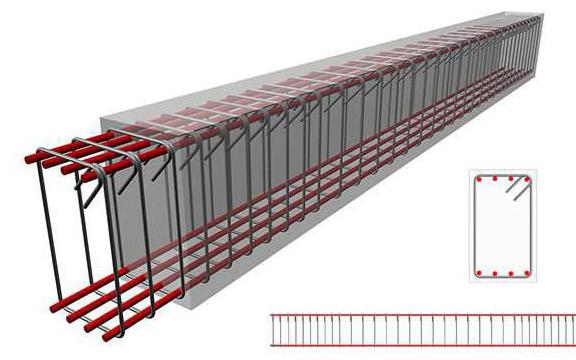

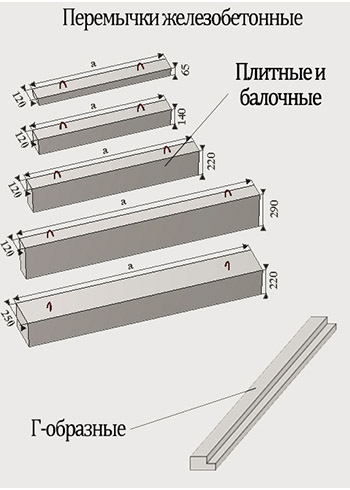

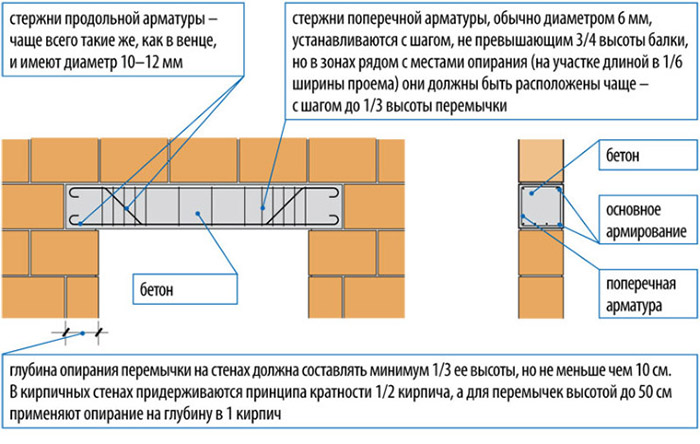

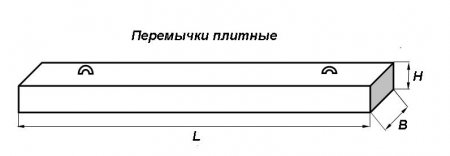

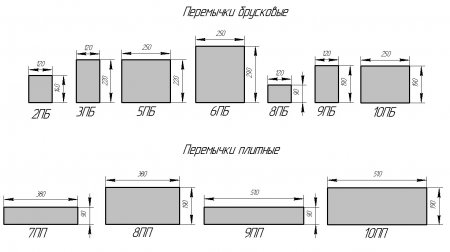

DesignThe reinforcement frame of the lintel provides its strength. It consists of longitudinal and transverse reinforcement. The standards provide for the use of both prestressed and non-prestressed reinforcement. The diameter and pitch of the rods is determined by calculation or according to standard designs. When casting lintels, heavy concrete with a density of 2200-2500 kg / m 3 is used. The required strength of concrete is determined by calculation, the mark of permeability and frost resistance - taking into account the environment. For lifting in the construction, there are sling holes or singing, as required by GOST. it is allowed to make with releases of fittings for construction in earthquake-prone areas. The nomenclature of commercially available jumpers is shown in the table of GOST 948-84. The standard provides for PB length from 1030 to 5950 mm with prestressing or non-stressed reinforcement. Their section is divided into 10 groups - from 125 x 65 (h) mm to 250 x 290 (h) mm. PP plate lintels are available in lengths from 1160 to 2980 mm with prestressing or non-stressed reinforcement. Their cross section is represented by 10 groups - from 380 x 65 (h) mm to 510 x 220 (h) mm. Beam lintels with a quarter of the PG type are provided only with non-stressed reinforcement from 1550 to 5960 mm in length. There are 8 variants of the section - from 250 x 290 (h) mm to 510 x 440 (h) mm. PF facade lintels are manufactured in lengths from 770 mm to 4280 mm with a cross section of eight groups - from 90 x 90 (h) mm to 290 x 90 (h) mm.

DesignationBrands of serial products consist of two or three groups and fully characterize reinforced concrete lintels: dimensions, bearing capacity, section, and so on. The second group contains the average permissible load (kN / m), The third group of markings contains information on the presence of releases of reinforcement, slinging loops, as well as various characteristics depending on external conditions. In additional marking symbols are used:

Full marking of reinforced concrete lintels may look like this:

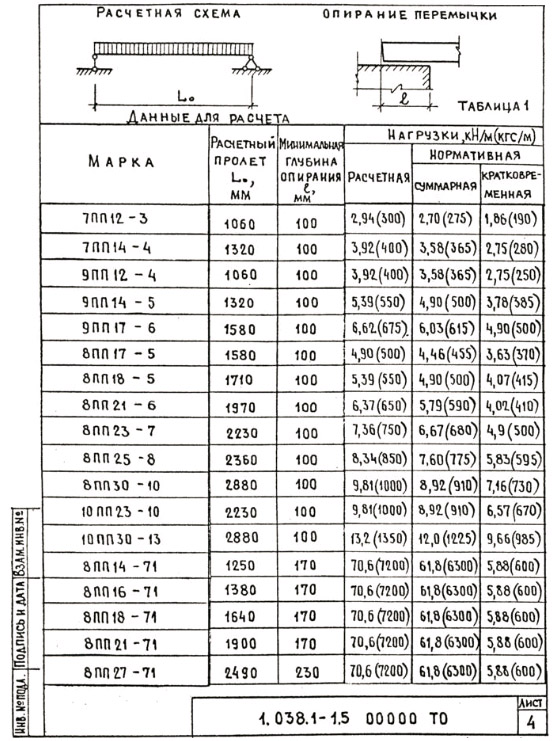

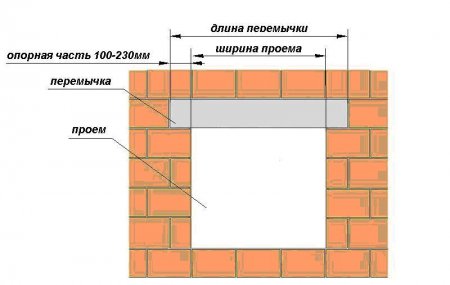

WarmingExterior walls of the house should provide the required level of thermal protection. This level is characterized by the value The larger it is, the higher the thermal protection of the building and, accordingly, the lower the heat consumption and the heating charge. Unfortunately, reinforced concrete is an excellent conductor of heat. Bridges form heat-conducting inclusions on the smooth surface of the walls - They lead not only to additional heat losses, but also in some cases to dew loss. To avoid this negative effect, it is necessary to insulate jumpers. If the building has additional insulation on the system of the ventilated facade or on the "wet technology" - no questions arise. But if the outer walls do not require additional insulation, the lintels are set indented from the outer surface of the wall. In this indent, an insert of effective insulation (for example, stone wool) is mounted and covered with plaster or other finishing material under the plane of the wall. Selection of jumper brandFor the correct choice of brand jumper, in addition to the destination, it is necessary to determine the bearing capacity. The permissible load of the product of each brand is specified in GOST "Reinforced concrete lintels". After completing the load collection and determining the span length, you can use the tables of the series 1.038.1-1, where each mark is compared: the estimated span, the support length and the load. Choosing reinforced concrete lintels, dimensions and sections, it is necessary to take into account the seismic hazard of the construction area.

Jumper calculationThe lintel is the supporting structure of the building, and its calculation should be handled by a specialist with relevant education and work experience. Nevertheless, for small projects, you can independently choose reinforced concrete lintels. The sizes of products are determined, guided by the SNiP "Stone designs". It is necessary to calculate the height of the laying above the lintel and compare it with the calculated span of the lintel. If the laying height is greater than the calculated span, then the carrier jumper is not needed. It is easy to explain: at a certain height, the wall above the opening is sufficient to have its own bearing capacity, and then the lintel does not need help. Knowing the proportion of masonry, it is easy to determine the brand jumper. The specific gravity values of the most popular masonry materials are given below:

It is necessary to consider the density of masonry material of a particular manufacturer.

Jumper installationNon-supporting lintels of door and window openings with a span of up to two meters are allowed to be laid manually, more than two meters - with the use of load-lifting mechanisms. The depth of the bearing is taken on a series, but usually not less than 200 mm in partitions and not less than 250 mm in the walls. Reference pads are checked by level. Lintels reinforced concrete for brick walls should be installed on the masonry, additionally reinforced with nets. To fill the entire wall thickness, lintels are installed in a package of several pieces. Extreme products should not protrude beyond the plane of the walls. At installation of crossing points it is necessary to observe their design orientation. Jumpers cannot be customized along the length of the trimming, since their reinforcement is uneven and is designed for the length of the span indicated in the product brand. Independent manufacture of jumpersIn the case when it is not possible to deliver the finished concrete products to the construction site, they can be made directly on site. Assembled frame set in the formwork. To create a protective layer of concrete reinforcement is raised, using plastic supports such as "stand" or "chair". Then the formwork is poured with heavy concrete, followed by compaction by vibration. After casting the reinforced concrete door lintels and window linings, it is necessary to withstand at least 24 days for hardening.

Jumper production in the spanIn private housing construction, ferro-concrete lintels for openings can often be made on site. This method is not very technological, but it eliminates the need for lifting and installation, which is very convenient in the absence of lifting mechanisms. When casting directly on the wall, it is possible to make arched reinforced concrete lintels. The dimensions of this design are determined by the individual project. Before the casting of the lintel, the masonry walls are brought to the required mark. Reference pads are checked by level and aligned with footing. Timbering in the opening is mounted formwork. The lower part of the formwork is made of a sufficiently thick board and is reinforced with supports. The pitch and cross-section of the supports shall be selected in accordance with the span length and the weight of the lintel, taking the weight of heavy concrete to 2500 kg / m cube. The supports are fixed to each other and to the wall structure. Window lintels require a quarter of a formwork to install a window block. Often, when building a house from blocks, suppliers of masonry material produce special U-shaped blocks. They are stacked on a support in the opening and perform the functions of permanent formwork. Such elements have the thickness of ordinary blocks in the masonry and do not emit a jumper on the surface of the wall. The formwork is mounted reinforcing cage, mounting loops in this case are not needed. After that, the formwork is poured with heavy concrete, compacting it with vibrating rammers. Flooded lintel leave for 24 days, after which the formwork is dismantled. One of the main positions in the assortment of any concrete products plant are jumpers. These are reinforced concrete products intended for overlapping window, door, arched openings in the upper part of them, as well as for some other construction works, for example, arranging a facade with protruding masonry. Jumpers play an important role in the construction of the building. Most developers get them from manufacturers. Plants guarantee the conformity of their products to state standards, use “correct” brands of concrete, high-quality reinforcement. An important factor is the affordable price, so the manufacture directly at the facility is rarely carried out. Mostly this occurs when overlapping non-standard openings. Main types and classification GOST 948-84, according to which standardization of products of this type is carried out, adopted in 1984. It is designed for buildings with brick walls, but it is allowed to use it in cases of arranging reinforced concrete lintels to block openings in walls made of other types of stone. According to GOST 984-84, 4 main types are distinguished: PB, PP, PG, PF. They are bars. Their maximum width can reach 25 cm. Standard length is 1030-5960 mm depending on the brand. For example, popular 2PB beams are available with a width of 120 and a height of 140 mm, while there are 10 lengths, and in each of them - 2 types, differing in weight and reinforcement. Slabs, their width is more than 250 mm, such plates consist of several bars, that is, PP is a block of reinforced concrete products PB. Concrete goods beam type. They have a special recess - a quarter, intended for arranging the places of contiguity of floor slabs. Facade. Exit to the facade of the building, the purpose - to block the openings with quarters.

MarkingAll reinforced concrete products manufactured at the factory comply with the standard classification of GOST. The brand is indicated by the manufacturer. To determine which type is in front of you, you need to decipher the notation consisting of letters and numbers separated by hyphens. Marking is carried out as follows: 1. the first group indicates the dimensions of the cross section, the type of lintel, its length; 2. the second group contains information on the design load (in kN / m) and the class of prestressed reinforcement; 3. The third group indicates the presence of mounting loops (p), anchor releases (a), as well as the possibility of mounting in special modes of operation. To ensure a high level of seismic resistance, concrete products with marking (C) are used, and in an aggressive environment - with a higher density of concrete (P) or (O).

For example, having a beam in front of you with a 2PB marking 10-1-p, we determine its dimensions and parameters:

In other options: 1. 8PP 21-71-АТV is a plate jumper with a length of 2070 mm with section no. 8 (380х190), designed for a load of 71 (more precisely, 70.61) kN / m with pre-stressed reinforcement of the Аt-V brand; 2. 5ПФ17-5 is a facade overlapping with a length of 1680 mm with section no. 5 (190 is height, 90 is a projecting part, 130 is a support zone), comes under a load of 5 kN / m

Appointment and calculations for loadsAs already noted above, the main function of products of this type is the overlapping of openings in buildings or ensuring the correct joining of interfloor plates. In the construction business there are such groups: 1. Bearing concrete. These are reinforced beams used to accept the load transmitted by the floor slabs. Maintain a weight of 3400-3700 kg / m. 2. Bearing (beams). Take the load transmitted masonry wall, located directly above the opening. 3. Pencils. Thin non-bearing; used for interior doorways. Pencil thickness - less than 120 mm.

4. Runs. Bearing, having a large size. 5. Rigel. These are girders with a notch (shelf) of considerable weight. Rigel designed to focus on their structures. In low-rise construction, primarily the first three types of reinforced concrete products are used. The size of the jumper and the maximum load on the beam is determined by experts when creating project documentation.

When building small outbuildings, baths, garages and similar facilities, the owner will cope with the calculations on his own. Jumpers are used for window and door openings corresponding to the 2PB mark. Their length can be from 1.03 to 2.95 m, and the cross section has standard dimensions of 120x140 mm. The weight of beams of group 2PB is in the range of 43-125. Window overlappings withstand a load of 200-800 kg / m, door - about 3700 kg / m. Concrete goods plants take into account the large weight of their products. To facilitate loading, unloading and construction work on beams and slabs, mounting loops or locking holes with a diameter of 30 mm are provided. Sometimes developers produce reinforced concrete lintels on their own. In this case, the use of “correct” concrete and reinforcement will be a prerequisite. Indeed, non-compliance with technology is fraught with the destruction of the building in a very short time. Beams are 0.3 m larger than the width of the opening. It should be noted that lintels for buildings with brick walls of factory production have a relatively low price. Therefore, they can always be bought in the right quantity. To fill reinforced concrete window lintels on the object are extra labor costs. After all, you will first need to mount the formwork, then pour the concrete, let it stand. And only after that continue laying. Finished PB beams will not significantly increase the cost of construction, but will significantly save time. Jumper prices

Spaka Interpraises LLC produces and sells reinforced concrete products made of reinforced concrete, which are widely used in the construction industry. The presence of modern production facilities provides the ability to produce a large range of quality products. Thanks to the multistage control, the customer receives concrete goods that meet all applicable norms and standards. Our enterprise makes and realizes the following reinforced concrete products at the optimum prices:

In addition to the above concrete products, we produce and sell other products made of reinforced concrete, and also offer to buy non-metallic materials - cement, sand, expanded clay. Full list of materials presented in the catalog on the site. Advantages of concrete products from LLC Spaka InterpraisesThe company uses only high-quality raw materials, special additives and components in the manufacture of products. The production of concrete products is based on the use of functional equipment and the latest technologies. Our products are distinguished by their strength, durability, reliability and meet all established requirements. The company employs highly qualified specialists who exactly follow the standards. Competent managers will help customers to choose concrete goods for the construction of objects for various purposes. An individual approach to the requirements and wishes of the customer provides the ability to effectively solve problems of varying degrees of complexity. Other advantages of buying concrete products from us:

Dial our contact number in Moscow and order concrete goods with delivery to the object! For overlapping window and door openings during the construction of buildings from bricks or blocks, as well as natural stone, they are most often used reinforced concrete lintels. Their use is recommended in the construction of administrative and residential buildings, as well as industrial premises of various types. Our company has long been producing high-quality iron - concrete products, including jumpers in Kazan.

|

Crossing points reinforced concrete for buildings with brick walls Reinforced concrete lintels are widely used in construction. Despite its small size and weight, concrete lintels occupy one of the leading places among reinforced concrete products. Reinforced concrete lintels are elements without which you cannot build a single house out of bricks, concrete or foam concrete blocks. They are designed to overlap the door and window openings in the walls of buildings for various purposes, provide strength and stability of the building structure, taking on a static load. Lintels reinforced concrete for buildings with brick walls are made in accordance with the model series 1.038.1 and GOST 948-84. AO TZHBI-4 produces bar and slab reinforced concrete lintels with non-tensioned reinforcement. Product marking is accepted according to GOST 948-84: Squared - PB (width up to 250 mm); Slabs - PP (width over 250 mm).

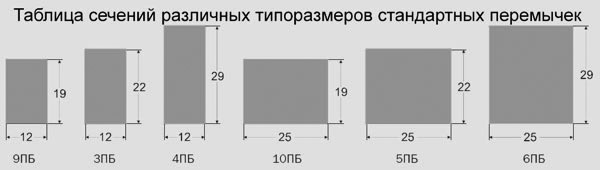

Slab and slab lintels are made of different sections. The sizes of sections of the standard jumpers made by JSC TZHBI-4 are presented below:

The lintels are designed for loads of their own weight, the weight of the brickwork above them and floors. From the point of view of bearing capacity, all jumpers can be divided into carriers and non-carriers. Non-supporting jumpers (rated load less than 800 kgf / m) - bear the load only from its own weight and masonry sections located above them. The masonry weight for them is taken into account as a short-term load. Bearing jumpers (design load of more than 800 kgf / m) - in addition to the masonry mass above it, bear the load from the ceilings based on these parts of the masonry. Maximum permissible load on bar lintels - from 100 to 3800 kgf; on plate jumpers - from 300 to 7200 kgf. For curtain walls, this value is: Bar lintels - 100 mm for lengths up to 3.0 m and 150-210 mm for lintels 3.0-3.9 m long; Plate lintels - 100 mm. For bearing walls, the value of the bearing should be: Bar lintels - 170 mm - 230 mm; Plate lintels - 100 mm (load 800-1300 kgf) and 170-230 mm (load 7200 kgf).

The jumper mark consists of alphanumeric groups in which information about it is encrypted. For example, the 9PB 13-37-p jumper brand is interpreted as follows: 9 - cross section of the lintel; PB - bar lintel; 13 - lintel length 1290 mm (in dm with rounding); 37 - design load on the jumper, taking into account its own weight of 37.27 kN / m (with rounding); p - the presence of mounting loops. If the lintels provide for the presence of anchor issues for fastening balcony plates, the index “a” is added to the marking. For example, 10PB 21-27-an. Reinforced concrete lintels in accordance with the technical requirements of GOST 948-84 are made of heavy concrete M200. Lintels 120 mm wide are reinforced with flat frames, and 250 mm wide with spatial frames. AO TZHBI-4 produces a very wide range of reinforced concrete lintels. The main dimensions, loads, weight jumpers are presented in the table.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Read: |

|---|

Popular:

How to fix a grip profile to a wall

|

New

- The interior of the room with wallpaper in flowers

- Piercing - “8 earrings, a lot of photos, how to care, how many heal, where to do, how to accelerate healing, what would I bring back?

- Window opening in a brick wall

- Finishing the bathroom with plastic panels

- Long narrow kitchen - layout (41 photos) of comfortable space

- White apron on the white kitchen - a classic combination

- Selection, consumption and features of applying paint on the wallpaper

- Designing a wardrobe - six simple steps

- Rating of the best oil heaters by user reviews

- What ear pierce guys normal orientation