Site sections

Editor's Choice:

- Bedroom design options in blue for a couple

- How to paint wallpaper for painting: tips and tricks

- Kitchen design in Khrushchev: useful tips for those who have a small kitchen

- How to punish noisy neighbors from above

- Design of a nursery for children of different sexes

- Shower cabin in the interior of a small bathroom

- Which light is better - warm or cold

- How to care for recently pierced ears

- What to do if the neighbors above are constantly poured

- Materials used for suspended kitchen ceilings

Advertising

| Punching aperture in the bearing wall. Punching aperture in a brick wall |

|

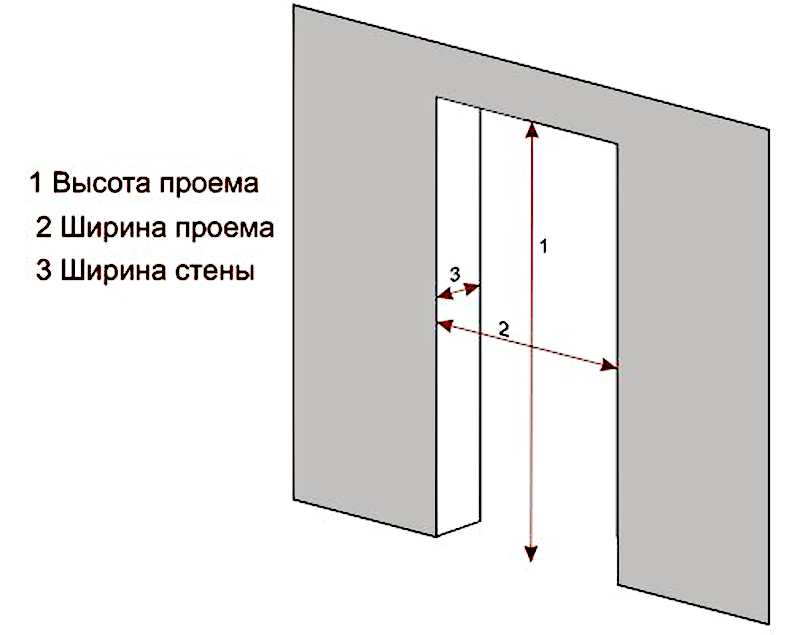

Deciding on the reconstruction of the building or redevelopment of an apartment or house, the owners are faced with the need to install additional doors and windows for which it is necessary to pierce new openings. Punching an opening in a brick wall is a responsible, difficult and not safe job. Before starting the punching of the opening in the wall, it is necessary to detect the wires, pipes and metal fittings hidden in it. To do this, you can use a small metal detector. Preparatory work

If necessary, the wiring is transferred to another place, and the distance from the hole to the chimney should be at least 300 mm.

Before direct penetration of the opening, it is necessary to install: A and B - beams; B - telescopic future opening; G - jumper. It is also important to know in which brick wall there will be a hole punching: carrier, non-bearing or it is a wall of rigidity. As for the curtain, then it can be determined if it plays the role of a dividing wall or if the draft states that the wall is curtain and did not rebuild it. Even if there is an overhead wall above this wall, then it cannot be argued that it is carrying, because the load distribution can be carried out via jumpers or steel beams supported on the bearing walls. If it is not possible to determine what wall it is, then approach it as a carrier. Although this and dismantling, nevertheless, certain tools are needed. It:

Parsing brick wallsUnbearers are dismantled from top to bottom to reduce the risk of collapse of part of the wall. If you need to pierce the opening in the brick wall to the ceiling, the marking is done. With the help of a hammer and a chisel, the top row is knocked out. Removing the following rows you need to remember that the brick can lie freely without adhesion to the masonry. The chisel is directed perpendicular to the wall.

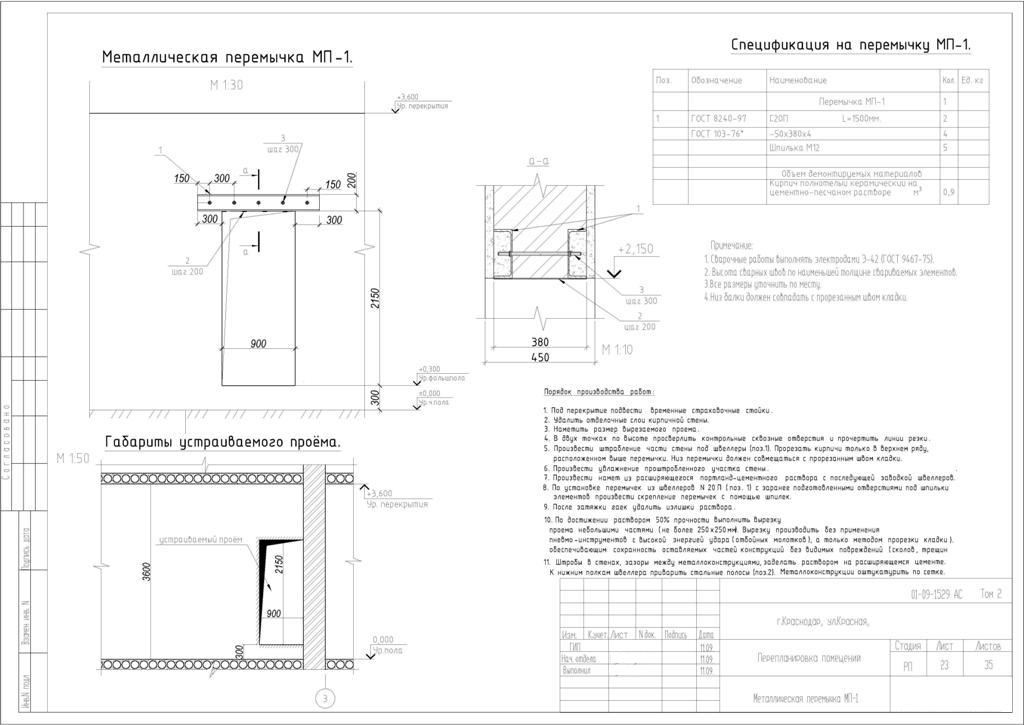

You need to make sure that it matches the jumper. This is done because the bottom mark of the lintel does not coincide with a multiple of the rows of bricks. Because of this, an extra row is removed and the jumper is mounted on the desired mark. With a large thickness of the walls fit two lintels and monolithic. The gap between the wall and the laid lintel is filled with cement mortar trowel. Further punching is done as described above. If there are concerns about the collapse of the brickwork, it is disassembled completely to the ceiling and spread on the new over the lintel. Punching openings in bearing wallsWhen work is carried out with load-bearing or reinforced walls, attention should be paid to the load and impact that the wall transmits to the base. The overlap is reinforced by so-called shoes, placed on both sides of the wall. A timber, a thick board is taken and a pole of non-circular timber is placed on it.

The process of punching the opening is done after the screed and the embedment of the beams. In all cases, it is required to maintain strength and stability, and this requires knowledge of the structures of floors and coatings. Concrete floors are best for supporting, but the use of wooden floors and drywall is not recommended. The bearing parts of the ceiling, supported on the wall, in the masonry of which the doorway is made, are temporarily supported. For safety, installation of jumpers is carried out in two stages.

It should be noted once again that when punching an opening in a brick wall it is necessary to treat with great responsibility.

Additional masonry is connected to the old masonry using spike ligation. It is performed in 1/2 brick with a height of 5 rows. The length of the laying is 300-450 mm.

When punching in a solid masonry, there is no need to reinforce the old one, only the slots for the supporting blocks are punched. They are installed later. Narrow opening deviceStructures up to 100 or 120 mm wide are considered to be a narrow element. In solid masonry, they make their way without supports. For the lintel, the groove is cut to the full width immediately. After the jumper is installed, the hole itself is punched. Vaulted Jumper

After punching the opening, it is necessary to weld metal strips from the bottom of the beams to reinforce the structure. The laying above the new device is also strengthened with a vaulted lintel. This is possible with a system width of 100 mm, and the height between the overlap and the opening is sufficient to transfer the load to the masonry. Then the design for the vaulted lintel is punched simultaneously with the main device. Laying start with the heel of the arch. The heel of the arch is chipped, the lower front surface intended for the device of the vaulted crosspiece is covered with a thin solution until the form of the vaulted overlap is obtained. The laying of this overlap is made of baked bricks on the mortar.

Niches and corners are used to house electrical appliances, built-in cabinets. When analyzing niches, there is no such need as retaining floors or walls if they are made in solid masonry. In this regard, you can completely disassemble a niche, and then build a jumper. If the walls are made of mixed masonry or they are fragile, then work on the liner support under the ceiling. The jumper is set in advance. We all want our home to be cozy, convenient and comfortable. Unfortunately, the typical layout of apartments can not provide the desired conditions. But it can be fixed by resorting to redevelopment of their living space. Redevelopment is a process that requires obtaining permission from various authorities, since unauthorized re-planning is prohibited by law. Although many repair and construction companies relieve their customers from going to instances and bureaucratic red tape - they have established connections in this area and will take over the whole process by settling all the formalities. In addition, they will perform a thorough analysis of the building materials from which the apartment or house was built, and will propose a project that would fully comply with state standards and safety requirements, responding to your wishes. You can perform redevelopment by moving window and door openings, as well as creating additional walls or partitions. Experienced specialists will do all the necessary work to strengthen the window and door openings, cutting new ones in the bearing walls, as well as creating additional openings, partitions and windows. It is important that all works be carried out using new technologies and not cause damage to the basic structure. But when making such a responsible decision, many immediately get a logical question: “How much does it cost to make an opening in a brick wall? And is it necessary to apply for this service to specialists? ” Proper planning of cutting openings in brick walls is a protection against expensive and consequential damages. For this reason, before starting work, be sure to consult with experts and find a plan for an apartment or house.

How much does it cost to make an opening in a brick wall: average prices on the market

Popular:

NewHow to restore the menstrual cycle after childbirth:

|