Site sections

Editor's Choice:

- Bedroom design options in blue for a couple

- How to paint wallpaper for painting: tips and tricks

- Kitchen design in Khrushchev: useful tips for those who have a small kitchen

- How to punish noisy neighbors from above

- Design of a nursery for children of different sexes

- Shower cabin in the interior of a small bathroom

- Which light is better - warm or cold

- How to care for recently pierced ears

- What to do if the neighbors above are constantly poured

- Materials used for suspended kitchen ceilings

Advertising

| Required air exchange rate for industrial premises. Ventilation rates in various rooms |

|

When designing ventilation systems, developers are obliged to pay attention to the instructions, recommendations and requirements of controlling authorities. The norms that need to be guided are SanPins, GOSTs, AVOK data and so on. They are quite detailed, numerous and complex, since they take into account a large number of parameters:

Basic calculation methods taken into account when regulating ventilationExperts are guided by the generalized tables. They take into account the necessary parameters and after calculating all possible methods, the greatest value is chosen - it is taken as the basis for the design (this approach is not used when organizing such systems in basins). Regardless of what exactly is described in them - air exchange in kindergarten or ventilation of warehouse premises, the norms are based on several key indicators:

In residential, public and industrial premises where people spend a lot of time, the calculation is made according to the following methods:

Features of norms for residential and office types of premisesThere are high requirements for living spaces - when designing ventilation, people should be safe. In such construction, a classical aeration scheme is usually used - natural exhaust, with channels. Contaminated masses are removed, first of all, from the sanitary zone - kitchens, bathrooms - and the space is considered to be the same pressure level and unpressurized by default, therefore, the calculation takes into account trimming of door panels and window parameters. Air exchange rates are divided by purpose of the premises:

This is a brief description, since housing design is a voluminous, complex industry, and it takes into account an impressively large number of regulatory indicators. The same, in principle, applies to office spaces - people spend a lot of time there, sometimes joining together in rather big groups. According to the design standards for such objects it is necessary to consider that:

Rationing of technical, production and storage facilitiesVentilation rates in industrial premises and storage areas are formed in a slightly different way. Here, besides the needs of people, it is necessary to take into account the features and technical requirements for equipment and the goods and substances contained in the room. If we talk about the sanitary component, then in the hall without windows it is necessary to organize the supply of outdoor air mass - 60 cubic meters per person. m / h Also standardized (by individual names):

As a rule, the system, which is organized indoors, combines natural and mechanical sources of ventilation and is based on the supply and exhaust principle. The main parameter is the multiplicity. For production and warehouse space it can vary from unit to 10. In general, the calculation of the multiplicity alone is insufficient and should be considered:

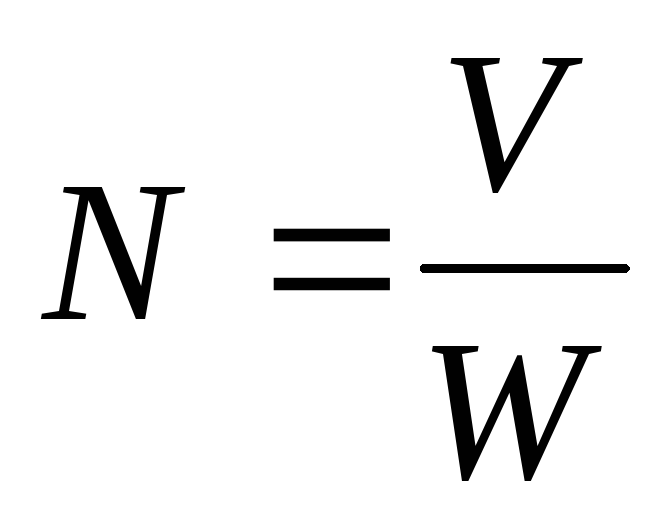

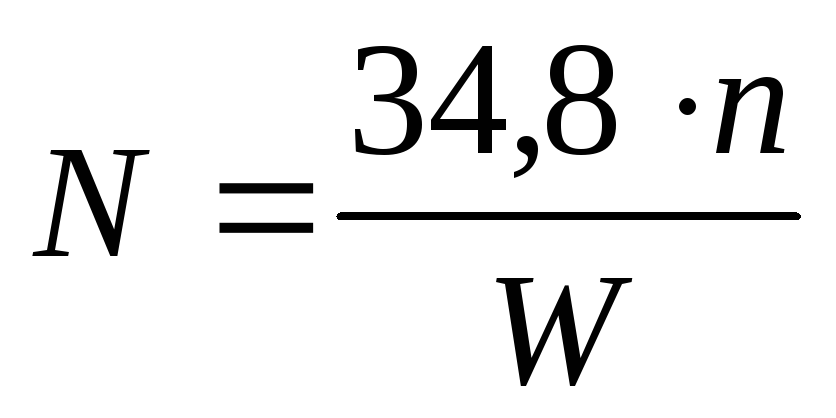

associate Professor Mironova E.M. laboratory work Calculation of the frequency of air in the room Methodical instructions Objective: Familiarize yourself with the concept of air exchange rate in rooms and acquire practical skills in calculating this meteorological value. Study questions: Determination of the frequency of air in the room, carried out by natural aeration. The calculation of the area of the open transom, through which atmospheric air enters the room, necessary to achieve a given air exchange rate. Determining the time of airing the room with periodic opening of the transom of known area. The order of work: To study the method for determining the air exchange rate of a room. Get a job assignment from a teacher. Carry out calculations to determine the rate of air exchange, the cross-sectional area for air exchange and air exchange time. 1. MAXIMUM AIR EXCHANGE IN THE PREMISES Air exchange is called replacing polluted air with clean air. Air exchange is divided into natural and artificial. Natural occurs due to the difference and pressure drop of air inside and outside the room. It is carried out with the help of periodic opening of the vents, transoms, windows (aeration), as well as through the slots of the walls, windows, doors (infiltration). Artificial air exchange is carried out by using various systems of mechanical ventilation and air conditioning. The air exchange rate determines how many times per hour it is necessary to change all the room air in order to clean it to the limit of permissible concentration of pollution (MPC). Air exchange rate N is given by the formula:

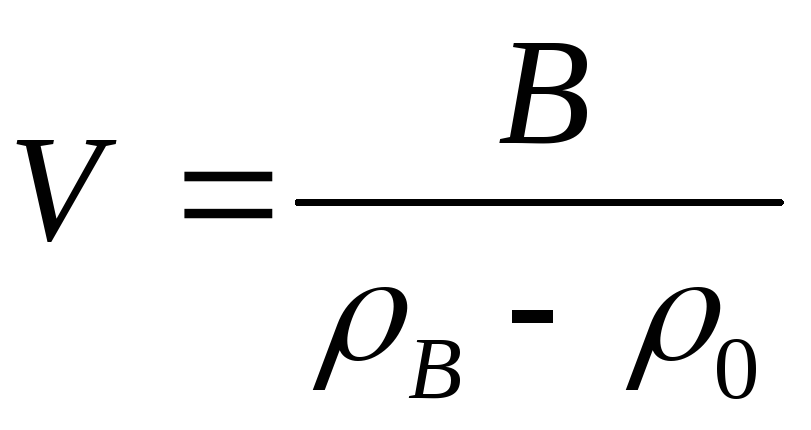

where: V(m 3 / h) - the required amount of clean air entering the premises within 1 hour; W(m 3) - the volume of the room. By natural aeration, usually three to four times air exchange is achieved, and, if necessary, greater frequency is resorted to mechanical ventilation. The volume of clean fresh air, which must dilute harmful gases to the maximum permissible concentration, is determined by the formula:

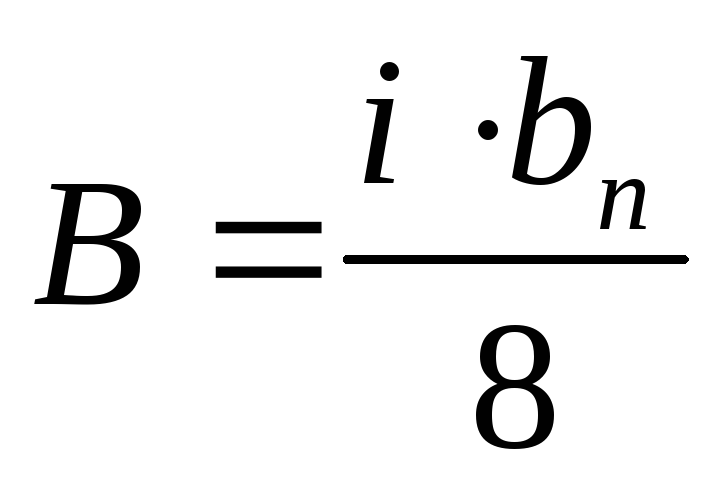

where: AT - amount of harmful substance (gas) entering the premises at 1 hour, mg / h; ρ AT - MPC of the harmful substance in the air of the working room, mg / m 3; ρ 0 - the concentration of the same harmful substance in the fresh air, mg / m 3. Amount of harmful gases ATin the air of the working room can be determined in several ways: a) Measurement of gas concentration per unit volume b using a gas analyzer. Then the amount of harmful substances is determined by the formula: B = a∙ b∙ W mg / h where: but- infiltration coefficient (for cameral workshops a = 1for garages a = 2); b - concentration of harmful substances in the air (mg / m 3 at 1 hour); W (m 3) - the cubic capacity of the working room. b) Determination of the consumption of harmful substances by all workers per shift (8 hours) in one working room

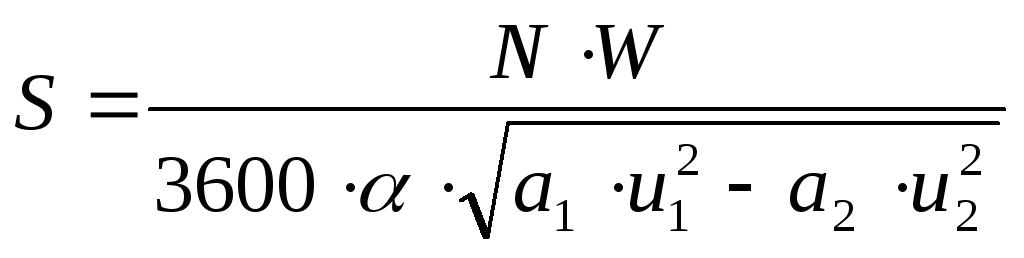

where b p - the amount of material containing a harmful substance consumed by all working in a given room, mg. c) Taking into account the release of carbon dioxide (CO 2) in the process of human breathing in the amount of 22.6 liters per hour. Then B = 22,6 ·n l / h where: n - the number of employees in the room. 2. CONDITIONS OF ACHIEVEMENT OF THE REQUIRED CAPACITY OF AIR EXCHANGE BY NATURAL AERATION Air flow Qpenetrating inside the room as a result of the pressure drop is determined by the formula: M 3 / s, (3) where: α

=

0,6 S (m 2) - the total area of sections through which air enters the room; u 1 (m / s) - wind speed on the windward side of the building; but 1

- appropriate aerodynamic coefficient, depending on the shape and design features of the building, u 2

(m / s) - wind speed on the leeward side, for average conditions but 2

- the corresponding aerodynamic coefficient,

For ensuring the set frequency of air exchange N The following condition is required: V = 3600 Q (4), where the coefficient of 3600 appeared as a result of the conversion of hours to seconds. According to (1), (3), condition (4) can be rewritten in the form:

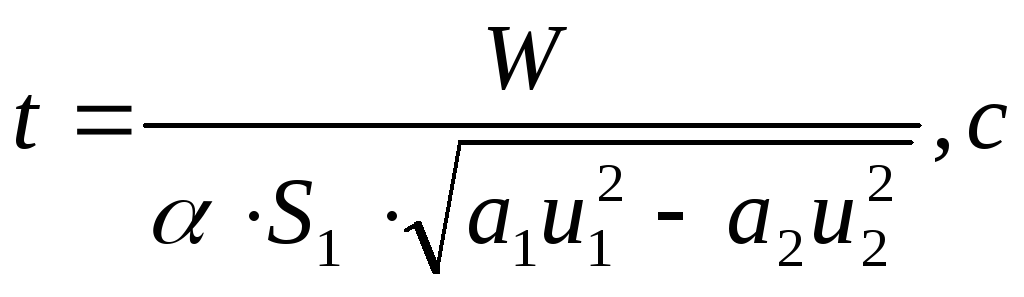

It is assumed that clean air enters the room through the cross section S continuously throughout the workday. In order to avoid drafts, as well as in the cold season, aeration of the room is carried out using periodic opening of the transoms. In this case, the frequency of air exchange shows how many times in 1 hour it is necessary to ventilate the room. Airing time t can be determined from the condition:

In the formula (6) area S 1 considered known. 3. EXAMPLES OF CALCULATION OF AIR EXCHANGE Task 1. Determine the air exchange rate of the production room height h = 3.5 m,in which 20 people work, there is 4.5 square meters per person. Air pollution occurs due to exhaled carbon dioxide. Forced ventilation is absent. Amount of harmful substance AT,entering the premises at 1 o'clock, is given by the formula: B = 22,6∙ n (l / h) The maximum permissible concentration of CO 2 is 0.1% or ρ AT = 1 l / m 3. Carbon dioxide content in atmospheric air is 0.035%, i.e. ρ about = 0.35 l / m 3. Then the volume of clean air Vrequired for n man, according to the formula (2), will be:

The air exchange rate is determined by the formula (1):

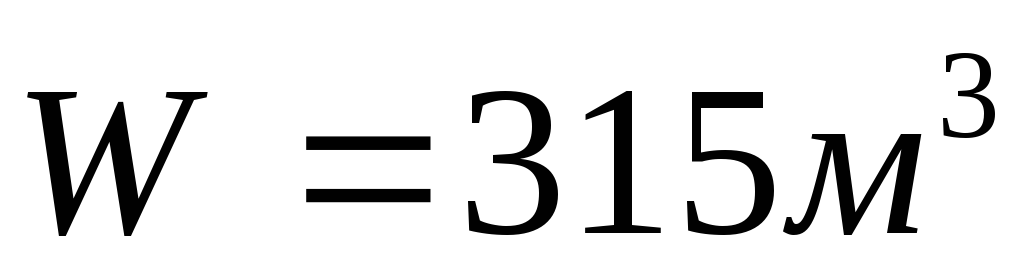

For the considered production premises n = 20 people, volume. According to the formula (7):

Therefore, if 3 times in 1 hour to replace the polluted air of the room with clean air, the concentration of carbon dioxide in the room will be below the maximum allowable. Answer: N = 3. Task 2. Determine the sectional area Sthrough which clean air enters the room to ensure the rate of air exchange N

= 3 indoor volume Wind speeds on the windward and leeward sides and the corresponding coefficients are given: u 1 = 5 m / s; but 1 = 0.8; u 2 = 2.5 m / s; but 2 = 0.3; α = 0.7. We use the formula (5):Consequently, the aeration of the working room can be carried out using a window that is open throughout the working day, S= 50 cm * 20 cm Answer: S = 0.1 m 2 Task 3. Determine the time airing room volume but 2 = 0.3; α = 0.7. We use the formula (6):

Consequently, two minutes is enough to completely ventilate a room of a given volume. Answer: t = 106 s. Aeration of a room with a capacity of 315 m 3, where 20 people work, can be done with the help of a permanently open vent with an area of 0.1 m 2. It is also possible to periodically, every 20 minutes, airing the room by opening a transom for 2 minutes, with an area of 1 m 2. 4. CONTROL TASKS FOR STUDENTS Indoors W, works n person. 1% of the premises occupied by furniture and industrial equipment. Determine the air exchange of the room as a result of natural aeration, considering the air pollutant carbon dioxide produced during human breathing. Determine the area S an open throughout the working day transom, providing a given rate of air exchange N. Determine the time t airing the room with periodic opening N time in 1 hour transom, area S 1 (S 1 \u003e S). The initial data for the assignment are given by the teacher. TOOLKIT to perform calculations for labor protection in graduation projects N. Novgorod 1. Calculation of air exchange in the production area .............................. 3 2. Calculation of air exchange in welding shops ........................................... ......... five 3. Calculation of local exhaust ventilation ............................................ ............. 15 4. Calculation of artificial lighting ............................................. ................... 18 5. Calculation of natural lighting ............................................. ..................... 32 6. Determination of noise level in industrial premises ................... 39 7. Calculation of vibration isolation .............................................. .................................... 46 8. Calculation of protective grounding ............................................. ......................... 52 9. Calculation of the null .............................................. ............................................ 57 10. Calculation of electromagnetic radiation ............................................. ........................ 60 11. References .............................................. .................................................. ... 62 Calculation of air in the production area. The calculation of the amount of intake air required for general ventilation is carried out from the condition of emission of harmful substances in the production area (for example, carbon monoxide CO) and excess of apparent heat. The calculation of air exchange given below is made in accordance with SniP 2.04.05-91 “Heating, ventilation and air conditioning. Design standards ”for the warm period of the year, as the most severe mode of operation of the mechanical ventilation system. 1.1.Calculation of air exchange from the conditions for the release of harmful substances:

where L in- the amount of intake or exhaust air, depending on the adopted scheme of mechanical ventilation, m 3 / c, G BP - the amount of harmful substances released in the production area mg / s, q MAC - the maximum permissible concentration of harmful substances in the room, mg / m 3 Determined from GOST 12.1005-88 SSBT “General sanitary and hygienic requirements for working area air”. q P- the concentration of harmful substances in the outside air supplied to the room, mg / m 3:

When several harmful substances are emitted into the air of the working area, the calculation is carried out according to the harmful substance for which the supply of clean air in the largest quantities is required. So, for example, in thermal shops during the work of quenching units. Running on natural gas, the air in the work area is polluted with carbon monoxide (CO). The amount of carbon monoxide entering the air of the working area is determined by the formula:

where AT- natural gas consumption, kg / h; b- the amount of waste gases generated during combustion 1 kg fuel, kg / kg (for gas furnaces 15 kg / kg); r- the percentage of CO in the exhaust gases (3-5%). Consumption of natural gas is determined by the formula: where a- specific fuel consumption by 1 kw power is assumed to be 0.58 kg / kWh; To p- the coefficient of operation of the furnace, taking into account the heating and regulation of the combustion process, is assumed to be from 1.2 to 1.5; N-the power of the furnaces kw. 1.2.Calculation of air exchange from the condition of the release of excess apparent heat. When allocating excess apparent heat in the production room, the amount of supply (exhaust) air is determined from the condition for compensating for the excess heat:

Here Q d- an excess of apparent heat in the production area, W, there is a difference between the apparent heat entering the room and the amount of heat leaving the room is determined from the formula: where q- specific excess of apparent heat, W / m 3 . In cold workshops (mechanical, assembly, etc.) the specific excess of apparent heat is at least q=23 W / m 3 In hot shops (foundry, forge, rolling, thermal, boiler houses, etc.) the specific excess of apparent heat in the estimated work is assumed to be 100-200 W / m 3 in more accurate value calculations Q d determined taking into account the heat generated by all power plants. V- volume of industrial premises, m 3; From to- mass heat capacity of fresh air received by 1000 J / (kg × K); r in- supply air density taken 1.2 kg / m 3 ; t beats- the temperature of the air removed from the room, determined by the formula: where t norms- the normalized temperature in the room is selected according to GOST 12.1.005-88, depending on the category of room for the warm period of the year; D t- temperature gradient taken for non-production premises equal to 0.5 deg / mfor industrial premises equal to 1.5 deg / m; H- the distance from the floor to the center of the exhaust openings, m; t n- supply air temperature. Adopted at 5¸8 WITH 0 below the normalized temperature in the work area. |

| Read: |

|---|

Popular:

How to fix a grip profile to a wall

|

New

- The interior of the room with wallpaper in flowers

- Piercing - “8 earrings, a lot of photos, how to care, how many heal, where to do, how to accelerate healing, what would I bring back?

- Window opening in a brick wall

- Finishing the bathroom with plastic panels

- Long narrow kitchen - layout (41 photos) of comfortable space

- White apron on the white kitchen - a classic combination

- Selection, consumption and features of applying paint on the wallpaper

- Designing a wardrobe - six simple steps

- Rating of the best oil heaters by user reviews

- What ear pierce guys normal orientation

once in 1 hour (one)

once in 1 hour (one) m 3 / h (2)

m 3 / h (2) mg / h

mg / h - coefficient taking into account air flow through the transom in relation to buildings of industrial and urban type;

- coefficient taking into account air flow through the transom in relation to buildings of industrial and urban type; ;

;

;

; ,

, , m 2 (5)

, m 2 (5) (6)

(6) m 3 / h

m 3 / h once in 1 hour

once in 1 hour times in 1 hour

times in 1 hour .

.