Website sections

Editor's Choice:

- Download live wallpapers

- Video and live wallpaper for Windows from the developer Push Entertainment

- Download live wallpapers

- KPI System Implementation: Steps, Examples, Process and Performance Assessment

- What is a KPI system and how to work with key performance indicators

- Determine the type of economic system

- Economic systems and their characteristics

- How the pool affects the shape

- Inverse matrix definition of existence and uniqueness

- First wonderful limit

Advertising

| DIY door hinge templates How to set up a router for inserting door hinges |

|

If earlier, such tools as a hammer and chisel were used to install door hinges and locks, today the electric router is more often used. You can use the template for inserting hinges and locks - there are several options, so that the best option for any individual situation is selected. Device benefitsSuch a device will be convenient for both professional and home masterwho decided to install new doors. A device such as a milling cutter for inserting locks will be convenient due to:

The tool is intended for processing wooden surfaces, in particular for creating edges or grooves. With its help, it is possible to carry out such types of work as quickly as possible, such as tapping and installing locks in precisely fitted holes, and making notches for loops (their subsequent installation).

In addition, the milling cutter will not only conveniently install door fittings, but also round the edges, you can make neat profiled trims, create beautiful and reliable connections. Despite the apparent complexity, everyone can easily learn how to use the milling cutter - no similar tool is different from a curly loop, or drill. Types and models of a similar toolUsing the router, you can create almost any profile - both with straight and with rounded edges.

You can purchase a set of several cutters for the milling cutter, each of which performs a separate function and is designed for a separate type of work:

If you purchase a milling cutter for working with door leafs, then you can choose models with which you can ensure the formation of a hinge of the desired depth. There are also models with which you can embed a lock. The possibility of making spike joints is also offered.

There are professional models that are more suitable for masters who are engaged in installing doors daily. For homework, a simpler model is suitable. There are a lot of manufacturers of such devices, so you can choose a model not only in terms of functionality, but also in cost, quality and reliability. You can save money only if you plan to work with the tool extremely rarely, otherwise you should buy a professional model that is not only highly reliable, but also has a large assortment of functions.

A cheap model will quickly exhaust its reserve and, accordingly, there will be a need to purchase a new tool. Application areaAs already mentioned, to install the hinges and locks you can use the usual hammer and chisel, but when using them you should be prepared that you have to spend a lot of time and effort. Such a device is an indispensable tool for those who are professionally and daily engaged in the installation of doors. In order to perform all the necessary actions, the canvas must be fixed vertically by means of a slipway. Be sure the master must precisely mark the place where the installation of the lock or hinges is planned. The next step is to check - you need to attach the part to the marked area and see how perfectly the markup is made. For areas of the canvas that go beyond the marking, cover with masking tape to protect against damage.

In any case, such a tool as a milling cutter for inserting any type of locks and hinges will be relevant for any apartment or private house. The need to install doors arises infrequently, however, the need to replace the hinges, or to align the door leaf with the box, can occur frequently. If you deal with this on a professional level, then it is the milling cutter that will allow you to quickly and conveniently complete the entire front of the work. Although the device is convenient to use, to work with it you need some experience and knowledge why not all milling machines are acquired. To install the door with your own hands, it is necessary to correctly insert the door hinges. For accurate work, you need to have special tools, one of which is a template for loops. The simplest device helps facilitate the insertion process and minimize the possibility of errors. Types of TemplatesA hinge template is a device that restricts the movement of a hand or electric tool that removes a door leaf. The device is designed to simplify operation and minimize the number of errors that can lead to a door replacement. Devices can be:

The finished device costs between 2500 and 3500 rubles and in most cases is intended for professionals. If a template for home use is required, then it is more expedient to make it yourself with minimal cash costs. Template makingTo make a device for inserting loops on your own, you must:

Preparation of materialsTo make a template for inserting loops with your own hands, you will need:

The main elements are bolts, nuts and washers, which allow you to make a design for installing various types of loops. Instead of the wooden constituent parts for the manufacture of the template, you can use other materials available, such as plexiglass. Necessary toolsThe following tools will be required during the manufacturing process:

It is desirable that each tool be supplemented with various nozzles: drills, saws and so on. Manufacturing processThe template for installing loops is made as follows:

The presented design is intended for door hinges of various types and sizes. Setting loops with a patternThe door hinge template is suitable for both regular and hidden hinges. The necessary tool and instructions for using the device are exactly the same. Tools for tappingSo, to install the hinge on the door, you need to prepare:

To install furniture hinges, you will need a special nozzle on the router that can cut round holes. Sidebar InstructionsBefore proceeding with the insertion of door hinges, it is necessary to determine what distance of the hinges on the door is the most optimal:

Inset loops are made as follows:

When removing a tree, the thickness of the hinge and the fixing rod should be taken into account. If you make a minimum groove for the loop, then this will lead to a limitation of the functionality of the fittings. If the recess is too large, the hinge will be loosened and cannot hold the door leaf securely.

Similarly, the second part of the hinge is mounted on the door jamb. The entire process of installing door hinges using a special template is presented in the video. A template designed for installing door hinges can simplify the work several times and reduce the number of possible errors that can lead to the need to replace the door leaf. The device can be purchased at the store, which is most preferable for professionals who perform the insertion of loops daily or do it yourself. to make the template yourself, you will need 2-3 hours of free time and a small amount of materials. At minimal cost, you can make a fixture for yourself that will come in handy more than once during repair work. Hello. Today we’ll talk about the correct and easy installation of hinges with a milling cutter in the door leaf and door frame. The loops can be embedded in several ways, the most affordable one is, but it is the longest and the result will largely depend on the evenness of hands and accuracy. Milling cutter speeds up the process several times and the quality of each installed loop is the same, which is very good for serial insert. Personally, I install the hinges at a distance of 200 mm from the edge of the canvas, this, in my opinion, is the best option. We start marking, set aside 200 mm from the edges of the door leaf, this will be the edge of the hinge. We apply a loop to the label and align it. In order to mark the hinge on the canvas, I advise you to use a regular segment knife, just cut the veneer of the door leaf with it, guide the knife from the edge of the hinge to the center.

If you lead the knife in a different way, your hand may tremble and the scratch on the veneer will be outside the loop, which in the end will not be very good. Mark the edges of the loops in this way.

Now you need to prepare the router for work. I have a Makita RP0900 milling cutter, it’s such a normal device, but it has a significant drawback, as for me, it has a sharp start, when the button is pressed it jerks, because of this, it can be milled where it is not needed. The principle of setting the milling cutter is the same for all manufacturers. First, set the cutter. For milling loops, I use a conventional slot mill of 18 mm in diameter. Here is one:

We expose the cutter flush with the platform of the mill and tighten the screw, which is responsible for fixing the platform.

On the side of the milling cutter there is a depth limiter, on my milling cutter it is like this:

We insert a loop between the bolt and the stopper rod and fix it to fix the thickness of the loop.

We set the width of the insert of the loop, for this you need to attach the loop to the side stop of the router and turn the cutter so that the edge of the blade coincides with the edge of the loop, to adjust, we move or under the side stop until the blade matches. When setting up the router, it must be de-energized, otherwise you run the risk of becoming a person with nine fingers.

We check our depth settings on a piece of wood. Personally, I check immediately on the door leaf, just make a small call in the middle of the hinge. I put a loop and look flush with the door leaf or not. If not level, then adjust the setting and again try the depth.

After adjusting, we mill the loop. Here, very carefully, so as not to mill excess.

We mill a little without reaching scratches.

With a chisel, make the corners straight and remove the excess to scratches.

The result should be a rectangular groove into which the loop ideally becomes.

We mark places for screws and drill holes of a slightly smaller diameter than the screws themselves.

Mark the hinges on the door frame. On the side rack from the top, we postpone the thickness of the part of the door frame, which will be on top. In my example, the thickness of the door frame is 25 mm.

We add 3-4 mm to the gap from the door leaf to the frame and apply a side pillar to the door leaf, combining this mark with the edge of the door leaf.

Transfer the edges of the hinges from the door leaf to the side pillar of the door frame.

Then we follow all the same steps as with the door leaf. Mark with a knife, mill, clean with a chisel. If door frame has a quarter, then when milling you need to use a gasket whose thickness is equal to the height of this quarter. After milling all the loops we fasten them in their places.

This is how the hinges are installed using the manual router. Installation of a wooden interior door begins with embedding door hinges that serve as a kind of holder. To facilitate the insertion process, experts recommend using a milling machine and a special template. Patterns for the router for loops help to quickly determine optimal sizes excavation and perform all work as accurately as possible. The principle of operation of the deviceThe template for inserting loops with a milling cutter is a design that allows you to:

To use the device, you must:

Making a DIY hinge templateReady-made templates, which are sold in specialized stores, cost about 3.5 thousand rubles. Therefore, it is advisable to purchase a product exclusively by professional masters. For home use, the template can be made by yourself. Preparation for manufactureAt the stage of preparation for the assembly of the device, you must:

The design of the template implies:

For manufacturing, you will need:

Device assemblyThe assembly of the structure is as follows:

Self-production of the template will save money, since all structural elements can be made from existing materials. Setting the hinges with the router and templateThe process of installing loops using a template and a milling machine is as follows:

When working with a milling machine, safety precautions are required. The medium power device produces a high rotation speed, which can contribute to damage.

You can find out how to use the template and the milling machine for inserting loops by watching the video. Even beginners, not experienced masters, can engage in the installation of loops using a template and a milling machine. The main thing at work is to strictly observe all safety rules and carefully make the required measurements and settings. A milling machine is a manual power tool designed for curly processing of edges and grooves in wooden products. Rounded edges, profiled strips, beautiful joints, inset locks, the device of the notches for the hinges - all this and much more can be done by the router for installing doors. He is an indispensable assistant in the household, but not every master is familiar with him. Of course, this tool is a little more complicated than a drill or a curly saw, but it allows you to work wonders. Varieties of Hand MillingUsing the router, you can make various profiles with both flat and rounded edges. It all depends on the type of cutter that is installed in it. Currently in the markets you can buy whole sets of cutters, each of which is designed for a certain type and shape of a groove or hole.Milling machines are:

The door milling cutter, in turn, can be used for:

The use of electric routerYou can use a chisel and a hammer to install locks and hinges, but the use of a milling cutter greatly simplifies and simplifies the work process. For professional door installers, it is one of the main devices without which the craftsmen cannot imagine a tool case. Using a milling cutter, you can not only install, but even make interior doorshaving minimal skills and a huge desire. The risk of damage to the door unit when working with the milling cutter is minimized, the quality of the inserted lock and installed hinge will be higher, and the percentage error will be less. It should be noted that for a door hinge model without a frame, called a butterfly hinge, a milling cutter is not necessary.

Now it is necessary to insert a milling cutter of the appropriate plate size into the electric mill, adjust the depth equal to the thickness of the bar, and make a recess. Next, you can set the loop. To arrange a seat for the lock, a slot mill is used. Its locking system allows you to install the tool on both a vertical surface and a horizontal one. What to consider when choosing a manual routerThere are several factors that you should pay attention to when buying an instrument. One of the main is the estimated intensity of the use of the router. If there is not much work, but from time to time there is a need for carpentry, it is better to purchase an inexpensive model. At the same time, you should carefully consider the choice of the manufacturer. Self-respecting companies, even little-known ones, produce milling cutters not only for home use. The range of products they produce will necessarily include professional equipment. By the way, today there are a lot of manufacturers of power tools, but there is no recognized leader among them. Therefore, an additional criterion will be the cost, functionality and characteristics of the selected model.

The next important point is the ergonomics of the tool. It will be appropriate to hold the router in your hands before buying, ask the seller to turn it on and test it at idle. In this case, it is worth listening to whether there are any extraneous noises and knocks, how quietly the milling cutter works, pay attention to the presence of backlash and check the available electronics. |

| Read: |

|---|

New

- Arithmetic progression

- Sum of arithmetic progression

- How to find arithmetic progression?

- How to find the difference of arithmetic progression

- Ohm's complete law for a complete circuit

- Ohm's law - nowhere is easier!

- Basic electrical laws

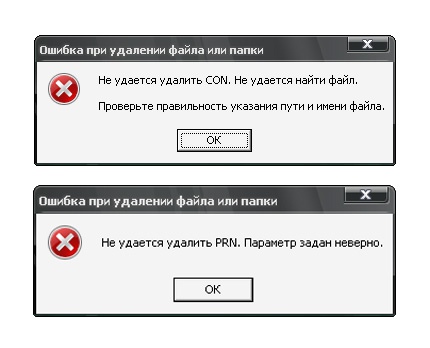

- Program to delete folders that are not deleted

- Driver installer: how to update everything at once

- Properties of logarithms and examples of their solutions

The canvas is laid on its side and fixed vertically with the help of a slipway. It is imperative to outline a place for inserting a lock or a loop, then attach the desired part or bar and outline their bottom and top in straight lines. Then transfer them using a square to the outside, and so that the lines are visible, stick two masking tapes on the marking, which will act as limiters.

The canvas is laid on its side and fixed vertically with the help of a slipway. It is imperative to outline a place for inserting a lock or a loop, then attach the desired part or bar and outline their bottom and top in straight lines. Then transfer them using a square to the outside, and so that the lines are visible, stick two masking tapes on the marking, which will act as limiters. With a large amount of planned work, one should not skimp. It must be remembered that cheap models are not designed for everyday loads, even if there are no complaints about the quality of the hand milling machine. Such a tool will quickly exhaust its reserve. And for a one-time job, it would be wiser to ask a milling cutter from a neighbor or rent it at the nearest specialized point.

With a large amount of planned work, one should not skimp. It must be remembered that cheap models are not designed for everyday loads, even if there are no complaints about the quality of the hand milling machine. Such a tool will quickly exhaust its reserve. And for a one-time job, it would be wiser to ask a milling cutter from a neighbor or rent it at the nearest specialized point.